Yeast’s Sweet Secret: Unlocking Wood Sugar for Better Bioproduction

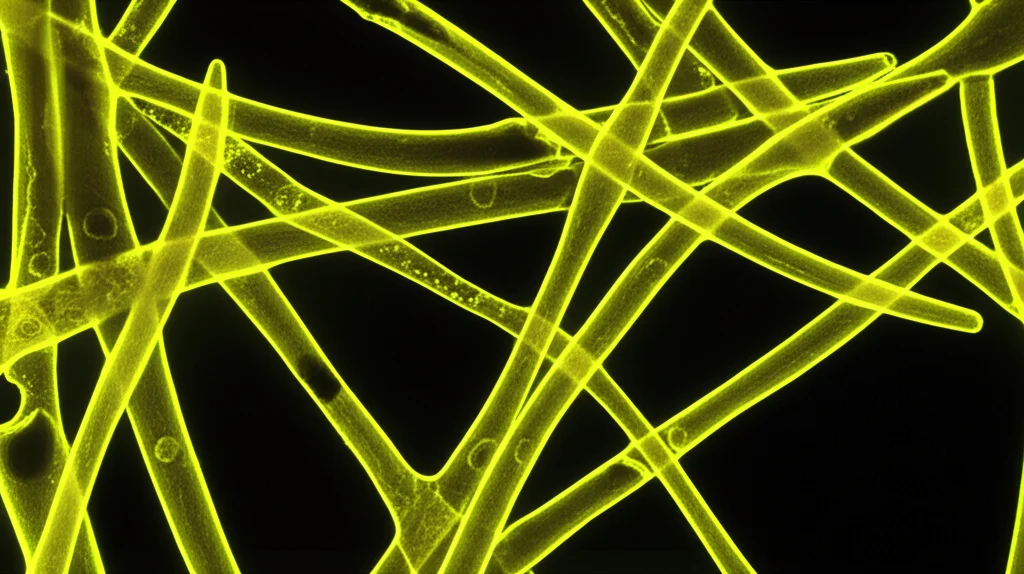

Hey there! Let me tell you about some seriously cool science I stumbled upon. You know how everyone’s talking about making things more sustainable, right? Less reliance on fossil fuels, more on renewable stuff like plants. Well, one of the big challenges is using *all* the bits of those plants, not just the easy parts. And a huge part of that plant goodness, especially in things like wood (lignocellulose), is a sugar called xylose.

Why Xylose Matters

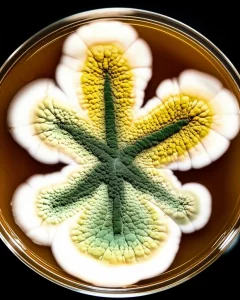

Think of lignocellulose as a giant buffet for making chemicals and fuels. Glucose is the main course, and yeast (*Saccharomyces cerevisiae*), our trusty little cell factory, is great at gobbling that up. But xylose? That’s like the side dish yeast often leaves on the plate. If we can get yeast to eat the xylose too, suddenly that plant buffet becomes way more efficient and, honestly, more economically feasible. Plus, yeast is already a superstar in fermentation – tough, reliable, and already used to making lots of cool molecules. Many of these valuable molecules, like those used in flavors, fragrances, and even some plastics, start from a central hub inside the cell called acetyl-CoA. So, getting yeast to turn xylose into acetyl-CoA? That’s the golden ticket!

The Yeast Challenge: Tight Metabolism

Here’s the tricky part: Yeast’s internal machinery, its central carbon metabolism, is super tightly controlled. It’s evolved over millions of years to be really good at growing and staying balanced, especially when its favorite food (glucose) is around. When you try to feed it something less familiar like xylose and then ask it to pump out tons of something else (like acetyl-CoA derived products), that tight regulation kinda fights back. It’s like trying to reroute a busy highway during rush hour – things get complicated, and the flow isn’t what you want. Previous efforts often focused on just getting yeast to *use* xylose or making the final product pathway better, but they didn’t really dig into how the *central* metabolism changes when xylose is the main meal. This leaves us a bit in the dark on how to really push that xylose through the system efficiently.

Our Game Plan: Modular Deregulation

So, what did these clever scientists do? They decided to tackle this tight regulation head-on with what they call a “modular deregulation strategy.” Instead of trying to fix everything at once, they broke down the central carbon metabolism into different sections, or modules. Then, they used a bunch of different tools to loosen up the rules in each section, both at the genetic level (changing the DNA) and the enzymatic level (tweaking the proteins that do the work).

The toolbox they used was pretty impressive, including:

- Engineering promoters (the on/off switches for genes)

- Manipulating transcription factors (the master controllers of gene expression)

- Building biosensors (little detectors inside the cell)

- Introducing enzymes from other organisms (heterologous enzymes)

- Using mutated versions of yeast’s own enzymes

Their goal? To get more xylose carbon flowing towards acetyl-CoA and, as a test case in this study, towards a specific product called 3-hydroxypropionic acid (3-HP). And let me tell you, they saw some *remarkable* results!

Module 1: Building the 3-HP Factory

First things first, they needed a way to convert that acetyl-CoA into the target product, 3-HP. They set up a pathway using an enzyme from a different microbe (*Chloroflexus aurantiacus*) called MCR. This enzyme takes malonyl-CoA (which comes from acetyl-CoA) and turns it into 3-HP. They tinkered with this pathway, even trying split versions of the enzyme and different gene copy numbers, to get it working well. They found that getting the balance right between the different parts of the enzyme was key.

Finding the Right Switches: Promoter Power

Promoters are like the volume knobs for genes. Some turn things up high, some keep them low, and some respond to what the cell is eating. Since xylose metabolism is different from glucose, they needed to find promoters that worked well specifically when yeast was munching on xylose. They did a deep dive into how yeast genes were expressed on xylose versus glucose and found a whole bunch of promoters with different behaviors – some strong on xylose, some strong on glucose, and some that didn’t care much (constitutive). They even showed that using a xylose-responsive promoter for a key xylose-using enzyme made the yeast grow faster on xylose. Pretty neat, right? It’s like giving the yeast the right instructions for the food it’s actually eating. They also used these promoters to fine-tune the expression of the enzymes in their 3-HP factory module.

Tweaking the Conductors: Transcription Factors

Transcription factors (TFs) are like the conductors of the cellular orchestra, telling whole groups of genes when to play. Yeast usually acts like it’s in “aerobic respiratory metabolism” mode on xylose (think slow, steady energy burning), but the pathway to acetyl-CoA for making products is more like the “aerobic fermentative metabolism” mode it uses on glucose (think faster, product-oriented). The scientists wanted to nudge the yeast towards that glucose-like metabolic state even on xylose. They analyzed which TFs were more active on glucose versus xylose and then tried overexpressing (turning up) or deleting (turning down) some of the key ones. They found that boosting some TFs (like MBP1, GCR1, and GCR2) and removing others (like SIP4 and Mig1) helped push more carbon towards 3-HP, though the improvements from TFs alone were modest. This highlights how complex the TF network is in yeast – it’s not just one or two switches!

Module 2: Cracking the Glycolysis Code

Glycolysis is a central pathway that breaks down sugars. On xylose, this pathway isn’t as active as on glucose, and things get complicated because yeast also tries to do gluconeogenesis (making glucose) and the glyoxylate cycle at the same time. This can lead to “futile cycling,” where the cell wastes energy going back and forth.

Blocking the Back Roads: No More Futile Cycling

To fix this, they blocked some of the genes involved in gluconeogenesis and the glyoxylate cycle. Deleting genes like PCK1 and FBP1 (involved in gluconeogenesis) significantly boosted 3-HP production, confirming that this futile cycling was indeed a problem they needed to stop.

Boosting the Assembly Line: Enzyme Engineering

They also tried turning up the expression of the enzymes in the glycolysis pathway itself. Overexpressing individual enzymes gave small bumps in 3-HP, but overexpressing groups of enzymes from the “upstream” or “downstream” parts of glycolysis helped more. Interestingly, overexpressing *all* the glycolytic enzymes at once actually *decreased* production, showing that balance is super important in this complex pathway.

Swapping Parts: Heterologous and Mutant Enzymes

Another cool trick was bringing in enzymes from *E. coli* or using mutated versions of yeast’s own enzymes. Some key glycolytic enzymes in yeast are heavily regulated by things like allosteric control (where molecules bind elsewhere on the enzyme to change its activity) or phosphorylation (adding a phosphate group). By using enzymes from *E. coli* or yeast enzymes with mutations in these regulatory spots, they could bypass some of this native control. For instance, mutating the PFK enzyme (a key control point) had a big impact, showing its crucial role on xylose. Similarly, mutating Gpm1 helped increase flux, suggesting phosphorylation negatively regulates it.

Balancing the Books: Cofactor Management

Metabolic pathways need cofactors like ATP, NADH, and NADPH to work. They looked at how these influenced 3-HP production. Lowering ATP levels (using a chemical called benzoate) seemed to increase flux through glycolysis, though overall 3-HP didn’t necessarily go up. NADPH is important for making 3-HP, while NADH is generated in glycolysis. They introduced an enzyme (GapN) that makes NADPH and also tweaked the enzyme that makes NADH (Tdh3). Using a constitutive promoter for GapN gave a significant boost in 3-HP, and reducing NADH production slightly also helped. It’s all about getting the right balance of these energy carriers!

Module 3: Taming the Mitochondria Gatekeeper

When yeast has lots of glucose and oxygen, it exhibits the “Crabtree effect,” diverting pyruvate away from the mitochondria (where it would be fully burned for energy) and towards products like ethanol. On xylose, this effect is less pronounced, and more carbon goes into the mitochondria and gets “lost” for product synthesis. Pyruvate needs to get *into* the mitochondria via transporters (Mpc proteins). They found that on xylose, yeast uses a different version of this transporter (Mpc1-Mpc3) compared to glucose (Mpc1-Mpc2). By turning down the expression of MPC3 using a weaker promoter, they successfully reduced the amount of pyruvate entering the mitochondria, pushing more carbon towards the desired acetyl-CoA pathway.

Module 4: Rerouting Pyruvate (The PDH Bypass)

Once pyruvate is in the cytoplasm (outside the mitochondria), it needs to get converted to acetyl-CoA via the PDH bypass pathway. This pathway is also tightly regulated in yeast. They tried several ways to improve this:

- Overexpressing native enzymes (like Pdc1) – modest improvement.

- Using a mutant version of ACS (acetyl-CoA synthetase) to avoid regulation – surprisingly decreased production.

- Introducing an enzyme from *E. coli* (EutE) that directly converts acetaldehyde to acetyl-CoA – a nice 40% improvement!

- Bringing in a whole new pathway from other bacteria (using PO and PTA) that goes through acetyl phosphate – this was tricky! It seemed to generate reactive oxygen species (like H2O2), which hurt the cells. They had to overexpress antioxidant genes (like SOD1 and SOD2) to clean up the mess, and then they saw a significant boost in 3-HP.

This shows that sometimes you need to bring in completely new routes or fix unintended side effects to get things flowing.

Driving Towards the Product: Malonyl-CoA Control

Acetyl-CoA is converted to malonyl-CoA by an enzyme called Acc1, which is also heavily regulated. They used mutant versions of Acc1 that were less regulated by phosphorylation, and this significantly increased 3-HP production. They also tried replacing a regulatory part of Acc1 with a flexible linker, which also worked well.

Avoiding Fatty Distractions: The Biosensor Idea

Malonyl-CoA is also used to make fatty acids, which is a major competing pathway. To prevent carbon from being siphoned off into fats, they got clever. They built a biosensor system that could *detect* the levels of fatty acyl-CoA (an intermediate in fatty acid synthesis) inside the cell. This biosensor was designed to turn *down* the expression of a key fatty acid synthesis enzyme (Fas1) when fatty acyl-CoA levels got too high. It’s like an automatic shut-off valve for the fatty acid pathway! Initially, this didn’t work as expected, perhaps because acyl-CoA wasn’t accumulating enough. They then removed a gene (PXA1) involved in transporting acyl-CoA away, which helped. They also found a link between fatty acid metabolism and xylitol production (a common byproduct when yeast struggles with xylose) and had to remove another gene (Adh6) to reduce xylitol and boost 3-HP even more. This biosensor approach, once tweaked, significantly improved 3-HP production by helping steer carbon away from fats.

Putting It All Together: The Super Strain

The real magic happened when they started combining these strategies. They systematically integrated the most effective modifications from each module – blocking gluconeogenesis, overexpressing mutated glycolytic enzymes, introducing GapN, tweaking TF expression, downregulating MPC3, introducing the improved PDH bypass (with antioxidants!), and optimizing Acc1 and Fas1 control. Step by step, they saw the 3-HP production climb. The final strain, a combination of many of these changes, showed a *massive* increase in 3-HP production – a 4.7-fold jump compared to their already optimized starting strain on xylose, and roughly a *100-fold* improvement over the very first strain they tested! They even used fancy modeling (pFBA) to confirm that the metabolic flux was indeed being successfully redirected towards 3-HP.

Looking Ahead: What’s Next?

This research is a fantastic demonstration that you *can* rationally engineer yeast’s central metabolism to make it better at using non-glucose sugars like xylose for valuable products. They identified key control points in the pathway when using xylose, which are different from when yeast uses glucose. While they made huge strides, they also noted that the complex nature of yeast’s regulatory networks, especially transcription factors, still presents challenges. Future work might involve even more sophisticated ways to control gene expression dynamically based on what’s happening inside the cell, improving how the product (3-HP) gets out of the cell, making the yeast more tolerant to the product, and keeping the pH just right during fermentation.

Overall, this study is a brilliant example of how breaking down complex biological systems into manageable modules and applying a diverse set of engineering tools can lead to dramatic improvements in cellular performance. It really pushes the boundaries of what our little yeast factories can do with sustainable resources!

Source: Springer