UV Vision: Catching Oil Sheen in Produced Water, Real-Time!

Well hey there! Let me tell you about something pretty neat we’ve been looking into. You know that stuff called produced water? It’s a big deal in the oil and gas world – basically, it’s water that comes up from the ground along with the oil and gas. And it’s not just plain water; it’s often got a whole cocktail of organic and inorganic bits, plus chemicals they used during extraction.

Now, managing this stuff is crucial because there’s a *ton* of it globally, and if it’s not treated right, it can cause environmental headaches, especially in the ocean. Regulators have limits on how much oil can be left in it before it’s discharged. The usual way to check this is to grab a sample right at the pipe end and send it off to a lab. It gives you a snapshot, sure, but it doesn’t tell you much about what happens once it hits the big blue sea, how it spreads, or where the contaminants actually end up. That’s where dispersion models come in, but honestly, predicting how things move in a dynamic ocean is tricky business.

Traditional methods like gravimetric analysis, IR absorption, or GC-FID are okay, but they have their downsides. Some use nasty chemicals, others are sensitive to things evaporating, and they often need fancy equipment and experts, which isn’t always easy when you’re out on an offshore platform. Plus, they’re all about that “end-of-pipe” moment, not the real-time situation out in the water.

Why Real-Time Monitoring is a Game Changer

Imagine being able to see what’s happening *as* it’s happening, right there in the marine environment. That’s the dream, right? Produced water, being warmer and less salty than seawater, tends to float up, forming plumes on the surface. Sometimes, these plumes can create a thin layer of oil, what we call a “sheen.” You might have seen it – that shimmery, rainbow-like film on water. While a visible sheen is bad news, often the hydrocarbons in produced water are too spread out to see with the naked eye, even if they’re still above environmental limits further from the discharge point.

So, we need something smarter, something that can detect this stuff even when it’s not obvious, and do it remotely and in real-time. That’s where remote sensing comes in. People have used it for big oil spills, but applying it to the much thinner, more dispersed sheens from produced water? That’s a different ballgame, and that’s what got us excited.

Shining a UV Light on the Problem

Ultraviolet (UV) sensors have shown promise because oil tends to reflect UV light strongly. They’ve been good at spotting thin oil layers, even those less than 0.1 µm thick, which is perfect for the kind of subtle sheen we’re talking about with produced water. But usually, UV sensors are used to guess how *thick* the oil layer is, not how *much* hydrocarbon is actually in the water.

And that’s where our study steps in. We thought, “Hey, could we use UV sensing not just to *see* a sheen, but to actually monitor produced water in real-time and figure out the concentration of total petroleum hydrocarbons (TPH)?” This lab-scale study was our first crack at proving that concept.

We set out to answer a few key questions:

- Could UV sensors detect a sheen from produced water at really low concentrations, statistically different from just plain seawater? (Objective 1)

- Could they tell the difference between samples with different oil concentrations based on how intense the sheen looked? (Objective 2)

- How does time affect the sheen and our ability to detect it? Does it evaporate? (Objective 3)

- Can we link the UV sheen intensity directly to the TPH concentration we measure? (Objective 4)

- Where does the oil hang out in the water column, and does the amount on the surface match what the UV sensor sees? (Objective 5)

Getting answers to these would be super helpful for managing produced water discharges and making sure we’re meeting environmental rules, especially by spotting those surfacing plumes and knowing if they’re above acceptable levels.

Setting Up Our Little Lab World

We kicked off the experiments in Western Australia. We grabbed some local seawater and filtered it to make sure it was consistent. Then, we got our hands on some condensate (that’s like a light, liquid hydrocarbon) from an offshore platform. We mixed the condensate into the seawater at different concentrations, from zero all the way up to 19.5 mg/L. We kept everything at a steady 22°C to mimic average sea surface temps.

We used a mechanical stirrer to mix the samples really vigorously, like they might experience in the treatment systems on a platform before discharge. After mixing, we let them settle for just a minute. Then, we transferred these samples into amber glass jars – turns out, clear glass causes too much glare under UV light!

For each concentration, we made eight samples. Four of these we put under a UV camera and floodlight for 60 minutes, taking pictures over time. After the imaging, we did the TPH analysis. The other four samples we sent straight for TPH analysis right after preparing them. This helped us see if the imaging process itself, or just time passing, caused any of the volatile stuff to evaporate.

We did the UV imaging inside a custom-made container to block out external light and keep things consistent. We even put a sheet of muslin over the UV light to soften it and avoid weird spotlight effects in the pictures. (Trust me, the first few pictures looked wild before we figured that out!).

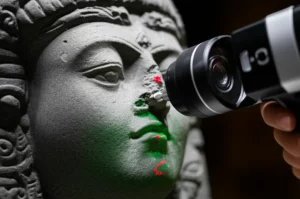

Peeking Through the UV Lens

UV imaging has some cool perks compared to other remote sensing methods like near-infrared. It’s really sensitive, meaning it can pick up even tiny differences in the sheen and potentially give us precise TPH numbers. It’s also *real-time* – we could take pictures every minute initially, then every 10 minutes, watching how the sheen changed. And it’s non-invasive; we didn’t have to mess with the water to see what was going on.

After taking the UV pictures, we used special software called ImageJ to analyze them. We did this thing called “flat field correction” to account for uneven lighting (even with the muslin, it wasn’t perfect, so we did a “pseudo” correction). Then, we “thresholded” the images – basically, we set a brightness level, and anything brighter than that was considered “sheen.” We figured out this threshold by looking at the pictures of pure seawater, which still showed a tiny bit of “background sheen” (just the water reflecting UV). We measured the average brightness of the “sheen” pixels to get a “relative sheen intensity.”

For the TPH analysis, we used an ERACHECK PRO analyser. We had to extract the oil from the water first using cyclohexane – it’s a standard liquid-liquid extraction method. After the imaging was done, we split the samples into a “top half” and a “bottom half” and extracted the oil from each separately. This let us see how the oil was distributed vertically in the sample.

We had to do a bit of math to account for the tiny bit of TPH we found even in the pure seawater samples (that’s normal with these tests) and to convert the analyser’s reading back to the concentration in the original seawater sample.

What the Data Told Us (The Aha! Moments)

Okay, so we crunched the numbers. The average relative sheen intensity (OMRSI) we measured with the UV camera generally went down over time. The biggest drop happened in the first 20 minutes. After that, things started to level off. This tells us that most of the sheen forms pretty quickly after the sample is mixed, and then evaporation starts taking over, especially for the lighter hydrocarbons in the condensate we used.

Interestingly, the lower concentration samples (0-3.9 mg/L) showed a less steep decline in sheen intensity initially. We think this is because the oil droplets might be smaller at lower concentrations, taking longer to rise to the surface. So, while buoyancy is driving the bigger droplets up fast, other things like mixing currents and evaporation are battling it out for the smaller ones, making the sheen intensity more stable at first. But eventually, evaporation wins out for all concentrations.

The really cool part? At a standard statistical confidence level (p-value of 0.05), the sheen we detected was statistically significant compared to the background seawater sheen for at least the first 20 minutes, even at low concentrations. This is a big deal because, as I mentioned, UV sensors were mostly used for much higher concentrations in oil spills before this. We showed they can work for the lower levels found in produced water!

At the 5-minute mark, the sheen intensities from different concentrations were statistically different from each other. This means the UV sensor could actually tell the difference between samples based on their original TPH concentration *right after* they settled. However, as time went on and the sheen faded due to evaporation, the sensor lost its ability to distinguish between similar concentrations, especially after about 30 minutes.

This highlights something important: for continuous discharges from offshore facilities, the surface layer is constantly being refreshed by new water coming up. So, the data from the *first few minutes* is actually the most relevant for real-world monitoring. If a UV sensor can detect a sheen above a certain threshold in that initial window, it’s a good indicator of potential environmental risk at that spot. Our results strongly suggest that UV sensing *can* be used to screen for produced water presence and even estimate its concentration in the field.

Where Does the Oil Go? Top vs. Bottom

We also looked at the TPH concentrations in the top and bottom halves of our samples, both immediately after preparation (5-min mark) and after 60 minutes of imaging. The TPH in the bottom half stayed pretty consistent over time. This makes sense because the smaller oil droplets (less than about 70 µm) aren’t really buoyant; they tend to stay dispersed throughout the water column.

But the TPH in the top half decreased noticeably over the 60 minutes. This confirms that evaporation is a major factor, especially for the lighter hydrocarbons that make up the condensate we used. The oil that rises to the surface (the larger, more buoyant droplets, likely between 70 and 100 µm) is exposed to the air and evaporates.

We compared the TPH in the top and bottom halves and, as expected, there was more TPH in the top half due to those buoyant droplets accumulating there and forming the sheen. The difference between the top and bottom TPH gives us an idea of how much condensate was specifically on the surface.

And here’s another cool finding: when we plotted the amount of condensate on the surface (calculated from our TPH analysis) against the average relative sheen intensity (OMRSI) measured by the UV camera at the 5-minute mark, we saw a strong linear relationship. This is exactly what you’d hope for – the brighter the sheen the UV sensor sees, the more oil is actually on the surface.

The Takeaway and What’s Next

So, what’s the big picture? Our lab study showed that UV sensor technology has excellent potential for real-time produced water monitoring. We could detect produced water at concentrations as low as 1.95 mg/L, which is meaningful for environmental risk management, and potentially even lower with further refinement. The UV sensor could differentiate between concentrations, especially in those crucial first few minutes after the water surfaces.

The fact that sheen detectability decreases over time due to evaporation isn’t a dealbreaker for monitoring continuous discharges offshore. Since the surface layer is constantly being replaced by fresh plume water, monitoring the *initial* sheen intensity gives you the information you need about the current discharge quality at that location. Detecting a sheen above a certain threshold essentially tells you, “Hey, the TPH concentration here is likely above X mg/L,” allowing for quick action.

The most exciting potential application we see for this technology, once it’s further developed, is putting these UV sensors on unmanned autonomous vehicles – think drones! Drones could fly over the discharge zone, scanning for surfacing plumes and measuring sheen intensity out to the compliance point. This would give operators real-time data to make decisions about treatment and discharge, helping them manage environmental risks effectively.

Of course, this was a lab study in a controlled environment. The real world has waves, currents, and varying ambient light, which could all affect how the UV sensor performs. Future research absolutely needs to tackle these physical factors to truly evaluate how well this technology would work in operational conditions. But based on what we’ve seen, UV sensing offers a really promising way to move beyond static, “end-of-pipe” checks towards dynamic, real-time monitoring of produced water in the marine environment. It’s a bright idea, literally!

Source: Springer