Squishing Steel Foam: How Hot Can It Get Before It Cracks?

Hey there! So, you know how engineers are always looking for materials that are tough, light, and can handle a beating? Well, metal foams are pretty high up on that list. Think of them like a metallic sponge – lots of empty space, but the solid bits give them surprising strength and amazing energy-absorbing powers. They’re popping up everywhere, from cars to planes to buildings.

There are a couple of main types: open-cell (like a regular sponge, connected holes) and closed-cell (like bubble wrap, sealed pockets). Closed-cell ones are usually better at things like insulation and carrying loads. At room temperature, these foams are rockstars for crash protection – they just crumple up and soak up the impact energy. Pretty neat, right?

Now, folks have done tons of work squishing these foams at normal temperatures. But what happens when you turn up the heat? That’s a whole different ballgame! Applications like heat shields, parts in hot engines, or even fire-resistant panels need materials that don’t just perform well, but can *survive* when things get seriously hot.

Most of the research on high-temperature performance has focused on aluminum foams. They’re popular, sure, but steel? Steel is known for being tough, and steel foams, especially a cool variation called Composite Metal Foams (CMFs), show some real promise for handling heat without losing their mojo too quickly. But honestly, there hasn’t been *enough* investigation into how these steel CMFs behave when the temperature climbs. And that’s where our little adventure comes in!

Meet the Steel CMFs: A Clever Twist on Foam

So, what exactly are these steel CMFs we’re talking about? Imagine tiny, hollow steel spheres – like miniature ball bearings, but hollow – packed together. Then, fill the spaces *between* these spheres with a stainless steel matrix. That’s a Composite Metal Foam! It’s a really smart design. The hollow spheres create the lightweight, porous structure, and the solid matrix holds it all together, making it stronger and helping it spread out stress evenly. This structure also helps stop cracks from just zipping through the material, and the sphere walls are less likely to buckle under pressure compared to some other foam designs.

Because of this unique setup, CMFs are great candidates for things like crash protection systems (they absorb energy beautifully) and even biomedical implants (though we’re focusing on the hot stuff here!). While we know a fair bit about how they act at room temperature, their behavior when it’s hot has been a bit of a mystery. And that’s a shame, because their built-in thermal insulation and energy dissipation make them *perfect* for high-temperature jobs like fire-resistant panels or thermal shielding.

We really needed to figure out the critical properties – like how stiff they are (elastic modulus), how much force they can handle before collapsing (plateau strength), when they basically turn into a solid block (densification point), and how much energy they can soak up – all when the temperature is cranked up.

Our Mission: Squish ‘Em Hot!

Our main goal in this study was to put these steel CMFs through their paces at various temperatures. We picked temperatures based on how stainless steel (the stuff they’re made of) behaves: room temperature (23°C), then 400°C and 600°C (where stainless steel starts to soften a bit), and finally 700°C and 800°C (where things get seriously challenging for steel). We skipped lower temperatures like 200-300°C because stainless steel doesn’t change much there.

We decided to hit them with *quasi-static compression tests*. Think of it as a slow, steady squish, not a sudden impact. This lets us see how the material deforms and handles load over time. We measured the force applied and how much the sample shortened (axial displacement). At room temperature, we also managed to measure how much the sample *expanded* sideways (lateral expansion) – this is key for calculating something called Poisson’s ratio, which tells you how much a material bulges when you squeeze it. Unfortunately, measuring that sideways bulge at high temperatures was tricky with our equipment.

To figure out the *elastic modulus* (how stiff the material is and how much it bounces back), we used a special technique: loading and *unloading* the sample repeatedly. Why unloading? Because when you first squish a foam, there’s a bit of irreversible deformation and tiny movements of the internal structure. The unloading phase gives you a cleaner picture of the material’s *true* elastic stiffness, free from those initial plastic effects. It’s like checking how much a spring bounces back *after* you’ve stretched it a little too far the first time.

Building Our Samples and Setting Up the Heat

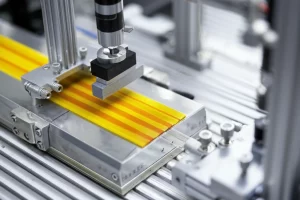

Making these CMF samples is a whole process! We used hollow steel spheres made with a technique called powder metallurgy, and filled the gaps with stainless steel powder. They’re packed into a mold and heated in a vacuum hot press. The samples we tested were little blocks, roughly 25.4 x 25.4 x 38.1 mm. We made sure they were big enough to contain at least ten hollow spheres in every direction – you want a representative sample, right? We also ground the ends perfectly flat so they’d sit nicely in the testing machine.

We calculated the density and porosity of our samples. Porosity is the amount of empty space, and for our samples, it was around 60%. This number turned out to be surprisingly important later on!

For the high-temperature tests, we needed a special setup. Our testing machine itself can’t handle the heat, so we built an insulated system with a furnace that wraps around the sample. We used special high-purity alumina rods to squish the samples because they’re super strong and don’t expand much when hot. We even pumped argon gas into the chamber to try and stop the steel from oxidizing (rusting) at high temps. We had to leave a tiny gap between the sample and the rods at the start to account for the sample expanding as it heated up. A thermocouple kept a close eye on the temperature, making sure it stayed right where we wanted it for 30 minutes before we started squishing.

Seeing How They Squish: The Stress-Strain Story

When you squish a metal foam, you typically see three distinct stages on a stress-strain graph (stress is the force per area, strain is the deformation):

1. Linear Elastic Region: At first, it’s like a spring. Stress goes up linearly with strain. If you stop, it bounces back to its original shape. This is where the material is just slightly bending and adjusting.

2. Plateau Region: This is the foam’s signature move! Stress stays relatively flat (or increases slightly) while the material deforms a lot. This is where the internal structure – the cell walls or, in our case, the hollow spheres and matrix – starts to buckle and collapse. This phase is where most of the energy absorption happens.

3. Densification Region: Eventually, all the empty space is pretty much gone. The material is now like a squashed block of solid metal. The stress shoots up dramatically with very little additional strain.

Steel CMFs are a bit different from traditional foams because of that matrix between the spheres. Their “plateau” isn’t perfectly flat; it has a bit of a slope. So, we fit lines to these three regions to define things like the “yield point” (where the plateau starts) and the “densification point” (where it ends). The plateau stress is basically the average stress in that middle region. The area under the curve up to the densification point tells us the total energy absorbed.

Looking at our experimental results, the stress-strain curves clearly showed these three phases at *all* temperatures. But boy, did temperature make a difference! As it got hotter, the curves got lower – meaning the material got weaker and less stiff.

The elastic region got shorter and shorter as temperature increased. At room temp, it went up to about 0.9% strain, but at 800°C, it was only 0.1%! This tells us the material starts to yield (deform permanently) much earlier when it’s hot.

The plateau phase still happened, spanning about 60% strain on average, regardless of temperature. This suggests that the *amount* of squishing before it becomes solid is mostly determined by the initial porosity – that 60% empty space we talked about earlier. However, the *stress level* in the plateau dropped significantly at higher temperatures.

And the densification phase? It was still there, with stress shooting up, but the peak stress reached was much lower at high temperatures.

Energy Absorption and Strength: The Hot Truth

We calculated the energy absorption and plateau strength from these curves. As expected, both dropped as the temperature went up. Going from room temperature to 400°C and 600°C, the drop wasn’t *too* dramatic. But beyond 600°C? Ouch. At 800°C, the CMF had lost over 80% of its energy absorption capacity compared to room temperature! This clearly shows there’s a temperature threshold where the material starts to really struggle.

What Did They Look Like After? (Visuals and Microstructure)

After squishing, we took a good look at the samples.

* At 23°C and 400°C, they looked pretty good – uniformly deformed, no weird bulges or cracks. Just nicely squished.

* At 600°C, they still deformed uniformly, but the surface had a bluish tint, suggesting oxidation (that argon wasn’t *perfect*!).

* At 700°C, things got dicey. We saw localized damage, like shearing and peeling, especially at the corners. The structure was starting to break down.

* At 800°C, it was pretty severe. Lots of shearing, peeling, and the material looked dark and heavily damaged. It had really lost its structural integrity.

We also peeked inside using a scanning electron microscope (SEM). Before testing, we could see the hollow spheres embedded in the porous matrix. The matrix itself had tiny pores too, from the manufacturing process.

After squishing at room temperature, we saw compressed matrix areas and cracked sphere walls. Looking super close, the fracture surfaces showed “dimples” – little cup-like features. This is a classic sign of *ductile* fracture, meaning the material stretched and deformed plastically before breaking.

At 400°C and 600°C, the microstructure still looked pretty intact, similar to room temperature, with deformed spheres and matrix. The bonding between the spheres and matrix seemed strong. At 600°C, we saw some light oxidation on the matrix surface.

But at 700°C and 800°C? Big changes. Where the outer layers had peeled off, we saw compressed spheres and areas where the matrix had detached from the spheres. The dimples were still there, showing ductile fracture, but they were less clear, especially at 800°C, where they were partially covered by oxide layers. We also saw evidence of grain boundary issues – the boundaries between the tiny crystals in the steel were weakening, contributing to the breakdown.

So, while the material still fractured in a ductile way even when hot, the overall structure was severely compromised by oxidation, thermal expansion stresses, and weakening at the grain boundaries at those higher temperatures.

Elastic Modulus: How Stiff Are They When Hot?

Remember those loading-unloading tests? We used them to measure the elastic modulus. We found that the unloading modulus was consistently *higher* than the loading modulus. This is typical for metal foams and confirms that the unloading phase gives a better measure of the true elastic stiffness, accounting for those initial plastic adjustments and sphere movements during loading.

As expected, the elastic modulus dropped as the temperature increased. The material gets softer and less resistant to deformation when it’s hot. However, the modulus values were still consistent within the loading-unloading cycles, suggesting the material retains *some* structural integrity even as it softens.

The Computer Simulation: Digital Squishing

Since we couldn’t measure everything experimentally at high temperatures (like Poisson’s ratio), we turned to computational modeling using ABAQUS software. We built a digital model of the CMF structure, representing the hollow spheres packed in a matrix. We used a special “crushable foam” model that’s designed for materials like this.

We fed the model the material properties we measured experimentally, especially the elastic modulus at different temperatures. For Poisson’s ratio at high temperatures, we made an assumption: based on studies of the parent material (stainless steel), we assumed it stayed constant at 0.2 (the value we measured at room temperature).

A cool part of the modeling involved dealing with how foams deform. Unlike solid metals, foams change volume a lot when you squish them. The standard math for “true stress” (the actual stress on the material as its shape changes) doesn’t work directly. We introduced a correction factor (K) to account for this volume change. When we fitted this correction factor to our room temperature data, we got K = 0.6. Guess what? That’s almost exactly the porosity (ϕ) of our samples (around 60% or 0.6)! This was a great moment – it showed that porosity isn’t just a physical property; it’s also a key mathematical factor governing how these CMFs behave under compression. We could then use this idea, along with porosity recalculated for thermal expansion, to estimate true stress at higher temperatures for the model.

We ran the simulations and compared the results to our experiments. Up to the densification point, the computer model matched the experimental stress-strain curves really well – the difference was less than 4%! This agreement is a big deal. It validates our model and, importantly, supports our assumption that Poisson’s ratio doesn’t change dramatically at those moderate elevated temperatures (up to 600°C).

Beyond the densification point, the model wasn’t quite as accurate (up to 10.5% deviation). This makes sense because after densification, the material acts more like a solid block, and our foam model isn’t designed for that solid-like behavior. But for predicting the energy absorption and plateau strength (which happen *before* densification), the model was spot on.

We didn’t even try to model the behavior at 700°C and 800°C with this basic model. The severe degradation we saw experimentally means you’d need a much more complex model that includes things like material damage, oxidation effects, and how cracks form. That’s a job for future research!

The Big Picture: What Does This All Mean?

So, what’s the takeaway from all this squishing and simulating?

Steel CMFs are pretty awesome materials, especially for applications where you need lightweight energy absorption and structural stability up to moderately high temperatures – let’s say around 600°C. They maintain their structure, deform predictably, and soak up energy effectively in this range. Think crash absorbers in vehicles, thermal shields in aerospace, or protective packaging for hazardous materials.

However, when the heat goes up further, to 700°C and 800°C, they start to fall apart. Thermal softening, oxidation, and weakening of the internal structure lead to significant loss of strength and energy absorption. They still offer *some* resistance, but their reliable performance range is definitely capped around 600°C.

Our study confirms the importance of porosity – that empty space is key to their behavior, both physically and mathematically. And the combination of experiments and computational modeling is a powerful way to understand these complex materials, even when experiments are limited.

There’s still more to explore, of course. We need better computational models to predict the behavior at *really* high temperatures, incorporating all those damage mechanisms we saw. And getting more experimental data on properties like Poisson’s ratio at high temps would be fantastic.

But for now, we’ve got a much clearer picture of how tough these steel CMFs are when the heat is on. They’re definitely a material with a bright future, as long as we use them within their temperature limits!

Source: Springer