Sisal Power: How We’re Supercharging Bio-Mortars for Greener, Stronger Buildings!

Hey everyone! I’m super excited to chat with you today about something that’s pretty close to my heart: making our construction materials not just strong, but also kind to our planet. We’re talking about bio-mortars, and specifically, how we can give them a serious upgrade using good old sisal fibers. You know, those tough fibers from the sisal plant? Turns out, they’re not just for ropes and mats anymore!

The Challenge with Traditional Materials

Traditional concrete and mortar are amazing, no doubt. They’re strong in compression, but sometimes they need a bit of help with tensile and flexural strength – that’s where steel reinforcements usually come in. But steel has its own issues, like the energy needed to produce it, and how it reacts to temperature changes. Plus, with our planet warming up, we really need to think about more eco-friendly and efficient building solutions.

Enter Natural Fibers!

This is where natural fibers, like sisal, step into the limelight. Researchers have been exploring adding these cellulose-based wonders to cement materials to boost strength, durability, and even thermal and sound insulation. The perks? They’re:

- Biodegradable

- Relatively low-cost

- Renewable

- Low density

- Good thermal insulators

It’s no wonder their use in construction has jumped by about 13% in the last decade! Sisal, in particular, is a star player because it’s widely available, cheap, and has mechanical properties surprisingly similar to polypropylene fibers.

The Sisal Story So Far – A Mixed Bag

Now, you’d think adding sisal fibers would always be a win-win, right? Well, the literature shows it’s a bit more complicated. Some studies have found that adding sisal fibers can actually decrease compressive strength, sometimes by quite a bit! Others have seen only slight improvements in flexural strength, even with chemical treatments like NaOH (sodium hydroxide) to help the fibers bond better with the cement. Most research has only looked at one or two factors at a time, like fiber length or NaOH concentration. This often leads to results like a 25% drop in strength or, at best, a tiny 9% gain. We knew there had to be a better way to unlock sisal’s full potential.

Our Mission: Cracking the Code for Super Sisal Bio-Mortars

So, that’s where this fascinating piece of research comes in! The goal was clear: how can we optimize a whole bunch of factors simultaneously to create a sisal-reinforced bio-mortar that doesn’t just match, but significantly outperforms standard mortar and previous fiber-reinforced attempts? We decided to look at four key things:

- Fiber content percentage in the mortar (how much sisal?)

- Fiber length (short, medium, or long-ish?)

- NaOH concentration percentage for treating the fibers (how strong a chemical bath?)

- Immersion duration in NaOH (how long do they soak?)

We wanted to see how these ingredients in our ‘recipe’ would affect both bending (flexural) and compressive strength and modulus. The dream? To get environmentally friendly, super-strong, top-quality mortars for the building industry.

The Magic Tool: Response Surface Methodology (RSM)

To tackle this multi-variable puzzle, we turned to a super clever statistical technique called Response Surface Methodology (RSM). Think of it like this: instead of testing every single possible combination (which would take forever!), RSM helps us design a smaller, smarter set of experiments to understand how different factors interact and influence the outcome. We used a specific design called a Box-Behnken design (BBDL29), which led to 29 different bio-mortar recipes to test. This way, we could find the sweet spot for production, save time, and still get robust results. RSM is a popular kid on the block, used in everything from bio-composites to optimizing chemical reactions!

Getting Our Hands Dirty: Prepping the Sisal and Mixing the Mortar

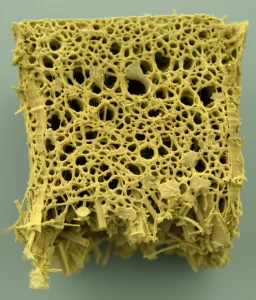

Alright, let’s talk about the star of the show: the sisal fibers! We got these commercially – they have a lovely beige color and an average diameter of about 200 μm. We used them both raw and chemically treated. Why the treatment? Soaking them in sodium hydroxide (NaOH) at different concentrations (1%, 3%, and 5%) and for various times (2, 8, and 14 hours) helps to clean the fiber surface and improve how well they stick to the cement matrix. It also makes them a bit more resistant to moisture. After their NaOH spa day, they got a quick dip in sulfuric acid, a good rinse with tap water, and then a final soak in distilled water to balance their pH. Then, we dried them, chopped them into 5, 10, and 15 mm lengths, and stored them in airtight bags, ready for action.

The bio-mortars themselves were mixed following European standards. The basic recipe was four parts sand, one part Portland cement, and half a part water. The sisal fibers, in their carefully measured amounts, were added gradually right from the start of mixing. We then poured these mixtures into stainless steel molds to create specimens for bending and compression tests. After 24 hours, we de-molded them and let them cure at room temperature for 28 days – patience is a virtue in material science, folks!

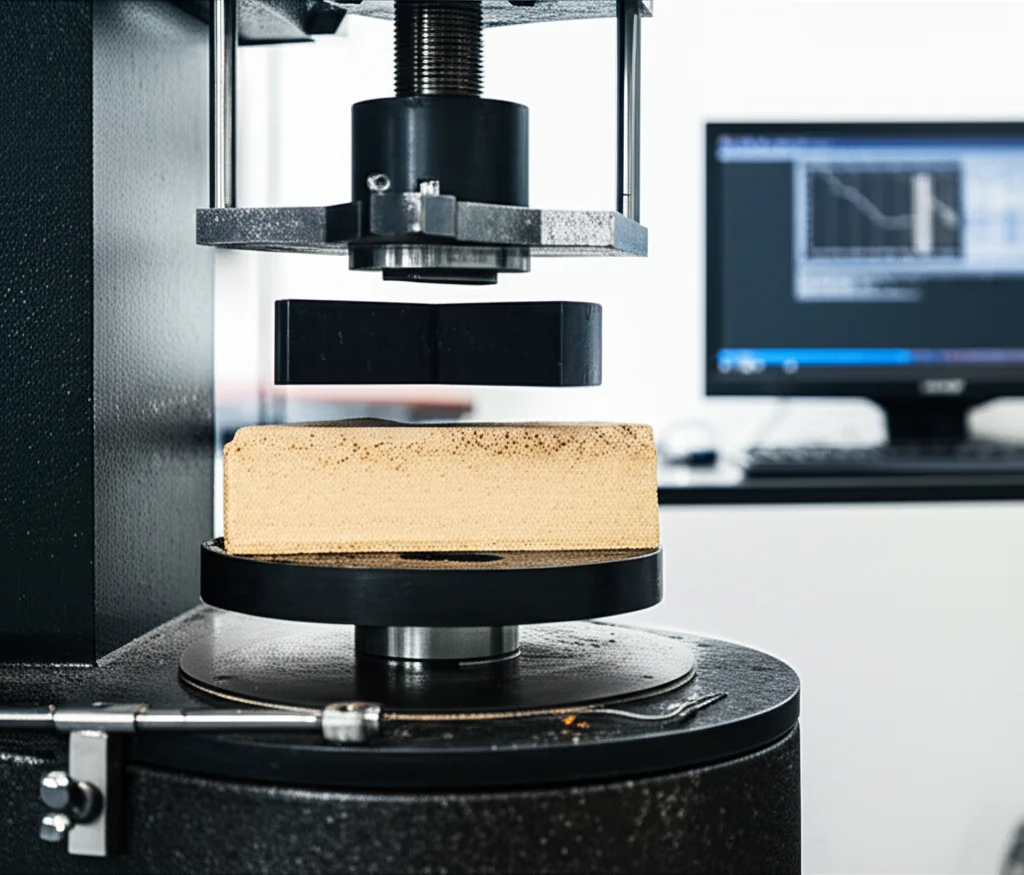

The Moment of Truth: Testing Time!

After 28 long days of curing, it was time to see what our bio-mortars were made of! We conducted three-point bending (3PB) tests and compression tests at room temperature using a universal testing machine. We were looking at two main things: the maximum stress the mortar could handle before breaking (strength) and its stiffness (Young’s modulus).

And boy, did we see some interesting results! The data (all 29 variations of it!) showed that adding sisal fibers could indeed either boost or, in some cases, reduce the mechanical performance compared to a control mortar (one with no fibers). This just goes to show how tricky finding that perfect balance can be.

Let me give you a taste of how individual factors played out. For bending stress:

- Increasing fiber content from 1% to 5% (with other factors constant) actually decreased stress by over 53%! This tells us more isn’t always better.

- Increasing fiber length from 5mm to 15mm led to a smaller reduction of about 9.6%.

- Upping the NaOH concentration from 1% to 5% for treatment caused a 20.8% drop in bending stress.

- Interestingly, a longer immersion time (from 2h to 14h) gave a slight increase of about 7%.

So, for bending, it seems fiber content was the biggest player, followed by NaOH concentration.

Now, for compressive strength, the story was a bit different:

- Increasing fiber content from 1% to 5% (again, others constant) actually increased compressive strength by nearly 20%!

- Longer fibers (5mm vs 15mm) led to a decrease of about 30%.

- Higher NaOH concentration (1% vs 5%) resulted in a significant decrease of almost 35%.

- And longer immersion time (2h vs 14h) also led to a substantial decrease of over 43%.

It’s clear that what’s good for bending isn’t necessarily good for compression, and vice-versa! The immersion time had the biggest impact here, followed by NaOH concentration and fiber length. It really highlights that you can’t just tweak one thing in isolation; it’s all about the interplay between these factors.

We even found a ‘neutral/critical zone’ – one bio-mortar mix (3% fiber, 10mm length, 3% NaOH, 8h immersion) had the lowest compressive strength. This showed that if the parameters aren’t harmonized, you can end up with pretty poor results. It’s all about finding that interdependent balance!

The Champion Mix and How Fibers Change the Game

So, after all that testing, which mix came out on top? Compared to our control mortar (no fibers), the star performer was a bio-mortar with:

- 1% fiber content

- 10 mm fiber length

- Fibers treated with 1% NaOH

- For an 8-hour immersion

This champion mix showed a whopping 66.3% increase in compressive strength and an incredible 82.8% boost in compressive modulus (stiffness)! For bending, the improvements were also fantastic: 34.8% more stress resistance and a 21.5% higher modulus. These are not just small tweaks; these are serious enhancements, way beyond what’s usually reported in the literature!

On the flip side, one of the worst configurations (5% fiber, 10mm length, 3% NaOH, 14h immersion) saw bending strength and stiffness plummet by 47.3% and 86.9% respectively. This really drives home how crucial optimization is.

But what’s actually happening inside the mortar when we add these fibers? We looked at the fracture damage. The control mortar, as expected, showed a brittle fracture – a crack starts and zips through it pretty fast. But when we added sisal fibers, especially at higher contents like 5%, the behavior changed to more ductile. The cracks propagated slower, and the fibers acted like tiny bridges, holding things together. They absorb energy and stop cracks in their tracks, or at least make them work harder to spread.

Longer fibers can be better at this crack-bridging, but only if they’re well-bonded and distributed. Too many fibers, or poorly dispersed ones, can create defects or voids, which isn’t what we want. In compression, the control specimen had one big crack. With 1% sisal, we saw multiple smaller cracks, indicating the fibers were distributing the stress. At 5% fiber, there were even more micro-cracks, which, while it sounds bad, can be a sign of energy dissipation before a catastrophic failure, especially if the overall strength is maintained or improved (which wasn’t always the case at 5% for all properties).

Decoding the Data with ANOVA and Building Predictive Models

Okay, so we had a mountain of experimental data. How do we make sense of it all and, more importantly, predict what would happen with other combinations? This is where the statistical heavy-lifting comes in, using something called ANOVA (Analysis of Variance). We used ANOVA to figure out which of our four factors (A: fiber content, B: fiber length, C: NaOH %, D: immersion time) and their interactions were statistically significant – basically, which ones really mattered for bending and compressive properties.

We looked at different mathematical models (linear, two-factor interaction, quadratic, and cubic) to describe the relationship between our input factors and the mechanical properties. The quadratic model turned out to be the best fit – it gave us high correlation coefficients (R² values), meaning it did a good job of explaining the variations we saw in our results.

For bending stress, factors A, B, and C were significant, as were the interactions AC (fiber content e NaOH) and BC (fiber length e NaOH). For bending modulus, A, B, C, and interactions AB, AC, BC, and CD were key.

For compressive stress, all individual factors A, B, C, D were significant, plus a bunch of interactions (AB, AC, AD, BD, CD). And for compressive modulus, A, C, D, and interactions AD, BC, CD played important roles.

Using these significant factors, the Design-Expert 12 software helped us cook up some pretty neat mathematical equations. These equations (Y1 for bending stress, Y2 for bending modulus, Y3 for compressive stress, and Y4 for compressive modulus) essentially allow us to predict the mechanical properties for any given combination of our four input parameters within the tested range! How cool is that? We could even visualize these relationships as 3D response surfaces, showing how, for example, changing fiber length and NaOH concentration together would affect bending strength. For instance, the highest bending stress (5.39 MPa) was found with 1% sisal, 5mm long, treated with 1% NaOH.

Finding the “Holy Grail”: Multi-Objective Optimization with Desirability

Now, the ultimate goal wasn’t just to understand these relationships, but to find the absolute best combination of parameters to maximize both bending and compressive properties simultaneously. For this, we used a nifty tool within RSM called the desirability function. It’s a way to combine all our objectives (high strength, high modulus in both bending and compression) into a single ‘desirability’ score, aiming for a value as close to 1 (or 100%) as possible.

The RSM analysis, using this desirability function, crunched the numbers and gave us ten ideal combinations! The top predicted solution suggested that a bio-mortar made with:

- 1.00% sisal fiber content

- 7.94 mm fiber length

- Treated with 1.85% NaOH

- For a 14-hour immersion

…would give us fantastic results: predicted bending stress of 5.393 MPa, bending modulus of 1.066 GPa, compressive stress of 37.524 MPa, and compressive modulus of 43.722 GPa.

Now, how does this compare to our best *experimental* result (the one I mentioned earlier with 1% fiber, 10mm length, 1% NaOH, 8h immersion)?

- Experimental Bending: Stress 5.39 MPa, Modulus 1.13 GPa

- Predicted Bending: Stress 5.393 MPa, Modulus 1.066 GPa (Very close!)

- Experimental Compression: Stress 34.94 MPa, Modulus 48.91 GPa

- Predicted Compression: Stress 37.524 MPa, Modulus 43.722 GPa (Pretty close! Errors of about 7.4% for stress and 10.5% for modulus)

The fact that these predicted optimal values are so close to what we actually achieved in the lab is a huge validation for the RSM approach! It means we can confidently use these models to fine-tune our bio-mortar production. We even got these cool contour plots showing the ‘sweet spots’ for different parameter interactions.

So, What’s the Big Deal?

Why am I so jazzed about all this? Well, this study really shows that by systematically optimizing the recipe, we can create sisal fiber-reinforced bio-mortars that are significantly stronger and stiffer than plain mortar. We’re talking about potential increases of over 66% in compressive strength and over 82% in compressive modulus! That’s a game-changer.

The key takeaways for me are:

- Sisal fibers are awesome: When used right, they can seriously boost mortar performance and make it more ductile.

- Optimization is crucial: Just throwing fibers in won’t cut it. The fiber percentage, length, chemical treatment, and immersion time all need to be carefully balanced.

- RSM is a powerful tool: It helps us navigate complex interactions and find the best formulations efficiently, developing predictive models that save a ton of experimental work.

This research paves the way for developing more sustainable, high-performance construction materials. Imagine buildings that are not only strong and durable but also have a smaller environmental footprint because they use renewable, natural fibers. That’s the future I’m excited about!

It’s truly inspiring to see how we can take a natural material like sisal, combine it with smart science like RSM, and come up with solutions that could help build a greener future. This isn’t just about lab results; it’s about pushing the boundaries of what’s possible in construction and material science. And who knows, maybe the next building you see going up will have a little bit of sisal power in its walls!

Source: Springer