From Old Batteries to Solar Power: Inkjet Printing Perovskites Sustainably

The Big Problem with Old Batteries

Okay, so let’s talk about something that’s a real headache for our planet: old lead-acid batteries. You know, the ones from cars, forklifts, backup power systems – basically, anything that needs a reliable zap of energy without being plugged in. They’re super useful, absolutely essential for lots of applications, but when they reach the end of their life? They become this toxic mess. Getting rid of them properly is a huge, costly challenge because of all that lead and sulfuric acid. It’s a major environmental concern, contributing to pollution if not handled just right.

Globally, electronic waste is piling up, and these batteries are a big part of it. We’re getting through electronics faster than ever, and while we’re getting better at recycling some bits, the toxic stuff like lead from batteries is still a major hurdle. We really need smart, sustainable ways to deal with this waste, especially if we’re serious about tackling climate change and reducing our carbon footprint. That’s where the exciting part comes in!

Turning Toxic Waste into Solar Gold

What if we could take that toxic lead from spent batteries and turn it into something amazing, something that helps power our future with clean energy? That’s exactly the innovative idea we’ve been diving into. Our big goal? To recycle the lead from these non-reusable batteries and transform it into high-value materials called lead halides (that’s things like PbI2, PbCl2, and PbBr2). Why these? Because they are key ingredients, the essential precursors, for making perovskite materials – the rockstars of next-generation solar cells.

Think of it as a superhero origin story for materials: taking something hazardous and giving it a new, incredibly powerful life in renewable energy technology. This approach isn’t just clever; it’s crucial. It minimizes environmental pollution by diverting toxic waste from landfills and converts that waste into high-value components needed for sustainable energy applications. It’s a win-win for the planet and for advancing solar technology.

The Recycling Journey: From Battery Paste to Pure Powder

So, how do we actually do it? It’s a multi-step process that requires careful handling. We started by collecting spent lead-acid batteries – big thanks to our partners who provided the raw material! Safety is paramount here, so we wore all the right gear to protect against the acid and lead. We carefully discharged the batteries, removed the top covers, and drained the acidic electrolyte, which was then neutralized properly. Inside, you find the lead plates and separators. These are the parts containing the valuable lead compounds we want to recycle.

The detailed recycling process involves several chemical transformations. We take the lead paste from the plates, which is a mix of lead compounds like PbSO4, PbO2, and metallic Pb. We dissolve it, clean it up (desulfurization), reduce some compounds, and then precipitate out the pure lead halides by reacting the lead solution with hydroiodic, hydrochloric, or hydrobromic acid. This results in beautiful, high-purity powders of PbI2 (yellow), PbCl2 (white), and PbBr2 (white). We used all sorts of fancy analytical tools – XRD, XPS, TEM, EDX, and optical spectroscopy – to check their structure, purity, and properties. And guess what? Our recycled lead halides were super pure and had the right crystalline structures and optical characteristics, just like the expensive stuff you’d buy off the shelf!

Why Perovskites and Why Print Them?

Now, why are we so excited about perovskites for solar cells? Because they’re incredibly efficient at turning sunlight into electricity, and potentially much cheaper to manufacture than traditional silicon solar panels. They have fantastic optoelectronic properties. But making them on a large scale, moving from tiny lab samples to big solar panels, is a challenge. Traditional lab methods aren’t always easy or cost-effective to scale up.

That’s where inkjet printing comes in! Yep, like your home printer, but instead of ink on paper, we’re printing layers of material onto a substrate. It’s a fantastic technique because it’s precise, scalable, and works on various surfaces, including flexible ones. It also wastes minimal material compared to some other deposition methods. We can control exactly where the material goes, layer by layer. This makes it a really promising candidate for mass-producing perovskite solar cells cost-effectively.

Printing Perovskite Thin Films

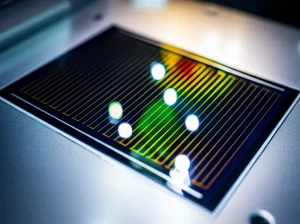

We took our recycled PbI2 and mixed it with other components to create a special perovskite “ink.” We used a high-tech inkjet printer (a Dimatix Fujifilm DMP-2800, if you’re curious!) to deposit this ink onto glass substrates. We prepared the substrates carefully and optimized the printing parameters – things like how fast the ink jets out, the voltage, and the spacing between drops. We even heated the printer bed to help the film form correctly. Right after printing, we annealed the films on a hotplate – basically baking them – to make sure the perovskite crystal structure formed perfectly. All of this was done in a controlled environment with specific temperature and humidity levels to get the best results.

We experimented with two different concentrations of our perovskite ink: 1 M and 1.3 M. We wanted to see how the amount of perovskite precursors in the ink affected the final film quality. Using optical microscopy, we could see the printed patterns. The 1 M ink, unfortunately, left gaps and looked a bit uneven – you could see the substrate underneath in places. Not exactly ideal for a continuous solar cell layer! But the 1.3 M ink? Much, much better. It resulted in a denser, more uniform film with fewer defects. This clearly showed that having a higher concentration of our recycled lead-based precursors in the ink is key to getting a high-quality, continuous perovskite layer.

Checking Out the Printed Films: Structure and Light Magic

Beyond just looking at them under a microscope, we needed to understand the films’ fundamental properties. We used XRD again to check their crystal structure. Both concentrations formed the correct tetragonal perovskite phase, which is what you want for efficient solar cells. However, the films made with the 1.3 M ink showed sharper, more intense peaks, indicating higher crystallinity and purity compared to the 1 M films, which had some leftover precursor impurities. We also calculated the size of the tiny crystals (crystallites), and they were slightly smaller in the 1.3 M films, which can sometimes be beneficial.

Then we looked at their optical properties – how they interact with light. Both films absorbed visible light strongly, which is essential for a solar cell. The 1.3 M films showed slightly higher absorbance, meaning they’re better at capturing sunlight. We also measured their band gap – basically, the energy needed to excite electrons and create electricity. The 1.3 M films had a slightly lower band gap (1.546 eV vs 1.557 eV), which is actually closer to the ideal range for perovskite solar cells, potentially boosting performance. Finally, we used photoluminescence (PL) spectroscopy. This tells us about defects and how efficiently charges move. The 1.3 M films showed a much stronger PL signal, indicating fewer defects and better charge dynamics. All signs point to the 1.3 M concentration being the sweet spot for high-quality films using our recycled lead precursors.

Ready for Solar? And What About the Cost?

So, are these inkjet-printed films ready for prime time in solar cells? Based on their excellent light absorption, optimal band gap, high crystallinity, and low defect density (especially the 1.3 M films), we’d say they’re highly suitable! These properties are exactly what you need for high-efficiency perovskite solar cells. The beauty of inkjet printing is its potential for scalability and use on flexible substrates, opening up possibilities for all sorts of new solar applications, like tandem cells (stacking different solar materials) or flexible panels you could put almost anywhere.

Now, let’s talk money. One of the biggest costs in making perovskite solar cells is the raw materials, particularly the high-purity lead iodide (PbI2). This is where our recycling process really shines. By sourcing the lead from spent batteries, we can significantly cut down on the cost of the perovskite precursors. Our assessment showed that the recycled PbI2 is roughly 40% cheaper than buying new, commercially available PbI2. This isn’t just a small saving; it makes the whole process much more economically viable for large-scale production. We also found that we could recycle some of the chemicals used in the lead extraction process, further reducing costs. The yields from our recycling steps were also very high – over 90% for converting lead paste to PbO and then to PbI2, and over 95% for the lead grid. This means we’re very efficient at recovering the valuable lead.

Scaling Up: Challenges and the Path Forward

Okay, so we’ve proven the concept works beautifully in the lab, both for recycling and printing. But taking this to industrial scale? That’s a whole different ballgame, and we need to be realistic about the hurdles. On the recycling side, handling massive quantities of toxic materials safely requires sophisticated automated systems and strict protocols. Maintaining the high purity and yield of the lead halides during large-scale chemical reactions is also more complex. And, of course, managing the waste by-products responsibly is essential for environmental compliance.

For the inkjet printing, scaling up means ensuring the ink properties (like viscosity and surface tension) stay perfectly consistent over huge volumes. We need to print quickly across large areas while maintaining the precision and uniformity we achieved in the lab. Printing on different types of substrates, especially large or flexible ones, also adds complexity. But we’re not stopping here! We’ve got solutions in mind:

- Automation: Using robots and automated systems for handling materials and controlling processes will boost efficiency and safety.

- Advanced Printing Tech: Exploring multi-nozzle printers and real-time monitoring systems will improve speed and precision on a large scale.

- Closed-Loop Systems: Developing ways to recycle and reuse solvents and other chemicals within our own process will minimize waste and costs.

- Partnerships: Working closely with industry experts is crucial to navigate the challenges of scaling up and bringing this technology to market.

Environmental Superpowers

Beyond the cool tech and cost savings, the environmental benefits of this approach are massive. By recycling lead from spent batteries, we’re directly preventing toxic lead from contaminating soil and water. Neutralizing the sulfuric acid properly stops acid leaks and environmental damage. We’re also conserving resources – using recycled lead means less need for energy-intensive and environmentally damaging mining and refining of new lead. It’s a perfect example of a circular economy, turning waste into valuable resources.

Recycling lead uses significantly less energy than producing it from scratch, which means lower greenhouse gas emissions. And inkjet printing itself is more environmentally friendly than some other coating methods because it’s so precise and uses less material and solvent, reducing waste and emissions. When you look at the whole lifecycle, this process has a much lower carbon footprint compared to traditional ways of dealing with battery waste and making solar cells. It really ticks all the boxes for sustainable development.

The Future Looks Bright (and Sustainable!)

So there you have it. We’ve taken a serious environmental problem – spent lead-acid batteries – and found a way to turn that hazardous waste into high-quality, cost-effective materials for the next generation of solar cells, using a cool, scalable printing method. We’ve shown that the recycled lead halides are pure and perform just as well as commercial ones, and that inkjet printing can produce high-quality perovskite films with excellent properties for solar energy conversion, especially when the ink concentration is optimized.

This research lays the groundwork for a truly sustainable and economically viable path for producing perovskite solar cells. It not only cleans up toxic waste but also helps power our future with clean, renewable energy. By addressing the scalability challenges head-on, we’re confident that this approach can contribute significantly to the widespread adoption of affordable, environmentally friendly solar technology. Pretty neat, right?

Source: Springer