R448A in Mini-Channels: Spilling the Beans on Its Boiling Behavior!

Hey everyone! Ever wondered how we keep things cool, like, really cool, in everything from your local supermarket’s freezer aisles to big industrial systems? Well, a huge part of that magic comes down to refrigerants and how they behave. But there’s a catch – many traditional refrigerants are a bit of a nightmare for our planet because of their high Global Warming Potential (GWP). Thanks to agreements like the Kigali Amendment, we’re on a mission to phase these out. This is where our story with a refrigerant called R448A begins!

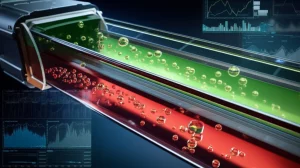

We’ve been diving deep into understanding R448A, which is a promising, lower-GWP alternative. It’s not just one substance, but a clever mix of five different components designed to hit that sweet spot of being eco-friendlier while still getting the job done efficiently. Our focus? How R448A boils when it’s flowing through super tiny tubes, what we call mini-channels. This is super important because how well a refrigerant boils (transfers heat) inside these channels dictates how efficient and effective a cooling system can be.

So, What’s the Big Deal with R448A and Mini-Channels?

R448A is a blend: R32 (26%), R125 (26%), R1234yf (20%), R134a (21%), and R1234ze(E) (7%). This complex cocktail is designed to be a good stand-in for older refrigerants like R404A, especially where non-flammability is a big must-have. Previous studies have shown it’s a pretty decent performer, sometimes matching the old guard. But when you shrink things down to mini-channels, things get… interesting. These tiny pathways are all the rage for making cooling systems more compact and efficient, but they also present unique challenges for how refrigerants boil.

Some researchers found that R448A’s heat transfer could be a bit lower than traditional refrigerants in certain setups, possibly due to something called “mass transfer resistance” and its “temperature glide” (because it’s a mixture, its components boil at slightly different temperatures). So, we figured, let’s get to the bottom of this! We decided to tackle this with a two-pronged attack: good old-fashioned experiments and some pretty slick computer simulations (CFD, or Computational Fluid Dynamics).

Hitting the Lab: Our Experimental Escapades

First up, we rolled up our sleeves and got our hands dirty in the lab. We built a specialized test rig to meticulously measure how R448A transfers heat and what kind of pressure drop it creates while boiling inside multiport mini-channel tubes. Think of these tubes as having several tiny parallel channels within a single, small tube structure. We played around with different conditions, like how fast the refrigerant was flowing (mass flux) and how much heat we were pumping into it (heat flux).

What did we find? Well, no huge surprises in some respects, which is good because it means physics still works!

- The heat transfer coefficient (a measure of how well heat moves) generally went up when we increased the mass flux. More flow means more turbulence and better mixing, which helps whisk heat away.

- Cranking up the heat flux also boosted the heat transfer coefficient, especially at lower flow rates. This is because more heat encourages more bubbles to form and dance around, a process called nucleate boiling.

- Interestingly, the shape and size of the mini-channels themselves made a difference, especially at lower flow rates. Tubes with smaller hydraulic diameters, larger perimeters, or higher aspect ratios seemed to do a bit better. It seems like having more surface area for bubbles to form and a good distribution of liquid helps. However, as we cranked up the flow, these geometric effects became less obvious, probably because convective boiling (heat transfer due to the fluid flow itself) started to dominate.

- And what about pressure drop? As you’d expect, pushing more refrigerant through (higher mass flux) or having more vapor in the mix (higher vapor quality) led to a greater pressure drop. More stuff moving faster means more friction! Heat flux, though, didn’t seem to bother the pressure drop much.

Based on all this juicy data, we even cooked up our own mathematical recipe – a correlation – to help engineers quickly predict how R448A will behave in similar mini-channels. Handy, right?

Diving into the Digital World: CFD to the Rescue!

Experiments are awesome, but they don’t always tell you the *full* story of what’s happening at a microscopic level. That’s where Computational Fluid Dynamics (CFD) comes in. It’s like having a virtual laboratory inside a computer, allowing us to see the invisible dance of fluid and heat.

Simulating boiling, especially for a non-azeotropic mixture like R448A (where components boil at different temperatures), is no walk in the park. The tricky part is that the more volatile components (those that boil off easily) tend to evaporate first. This changes the composition of the remaining liquid, which in turn changes its boiling point. It’s a dynamic, ever-changing situation!

So, we developed a new mass transfer model specifically for these kinds of mixtures. This model helps us account for two critical things:

- The preference for more volatile components to boil off first.

- The resulting rise in the bubble point temperature of the liquid as it becomes depleted of these volatile components.

We used the popular Volume of Fluid (VOF) method to track the interface between the liquid and vapor. We also made sure our digital setup, the mesh (think of it as the resolution of our simulation), was fine enough to capture the important details without making our computers cry from overwork. We ran simulations at a mass flux of 100 kg/m²s and tested different heating conditions.

Did Our Computer Model Get It Right?

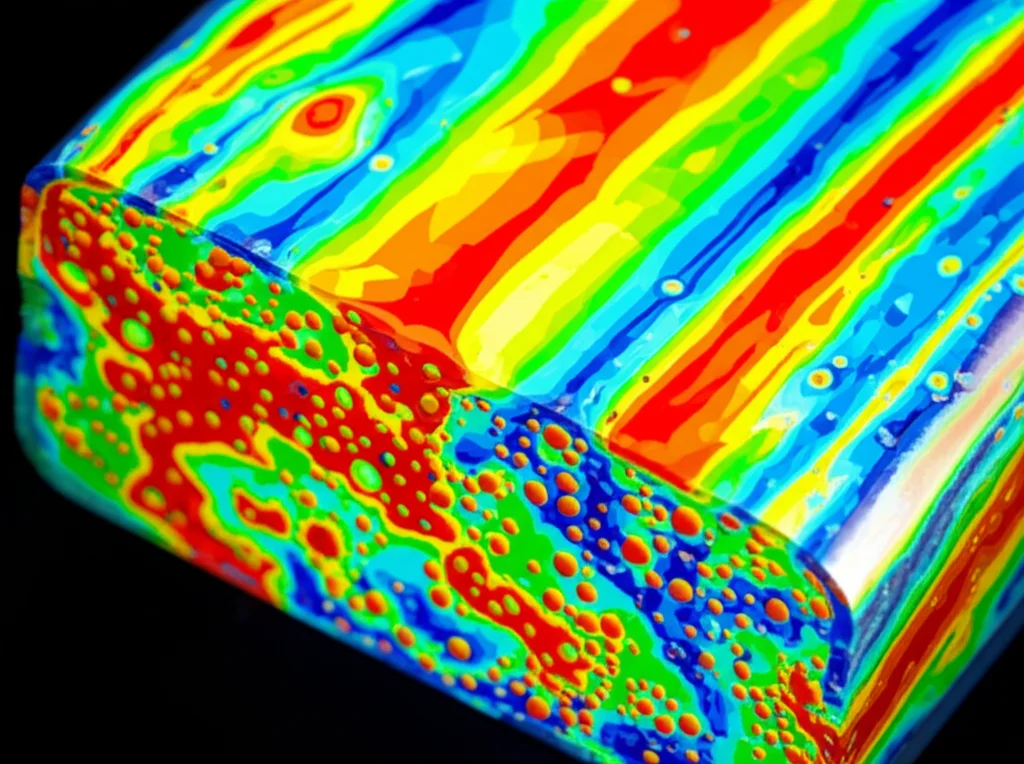

You bet! Well, mostly. We compared the heat transfer coefficients predicted by our CFD model with our experimental correlation and data from other researchers. The agreement was pretty good – generally within a 20% deviation, which is quite acceptable for these complex simulations. We’re talking about simplifying a 3D reality into a 2D model for some simulations, and averaging results over very short timescales compared to experiments. So, we were pretty chuffed with that!

We also looked at the flow patterns. Our simulations showed things like intermittent flow (where slugs of vapor and liquid chase each other) and transitional flow (moving towards a state where vapor flows in the core and liquid along the walls). When we compared these digital visuals to actual experimental observations reported in literature, they looked strikingly similar. It’s always cool when the computer “sees” what happens in real life!

The Secret Life of Boiling R448A: What CFD Revealed

This is where CFD really shines – it lets us peek under the hood. Our simulations showed exactly what we suspected about those pesky mixture effects:

- Volatile Components Bail First: As R448A flows and boils, the components that evaporate more easily (like R32 and R125 in this case) do indeed decrease in concentration in the liquid near the heated wall. Conversely, the less volatile components (R134a, R1234yf, R1234ze(E)) become more concentrated there.

- Bubble Trouble (Temperature Glide): This change in liquid composition means the bubble point temperature (the temperature at which it starts to boil) of the liquid near the wall actually increases as it moves along the channel. This reduces the effective superheat (the temperature difference driving boiling), which can penalize bubble formation.

- The Wall’s Resistance Layer: Because the less volatile stuff builds up near the wall where evaporation is most intense, it forms a kind of “diffusion layer.” This layer makes it harder for the more volatile, easy-to-boil components from the bulk liquid to reach the hot wall. This is that “mass transfer resistance” we talked about, and it can put a damper on the whole boiling process.

It’s like the refrigerant is constantly changing its mind about when it wants to boil as it travels along! These insights are crucial for designing more efficient heat exchangers that can handle these complex fluid behaviors.

So, What’s the Big Takeaway?

Our journey into the boiling world of R448A inside mini-channels, using both real-world experiments and powerful computer simulations, has given us some pretty neat insights. We confirmed that factors like mass flow and heat input significantly jazz up heat transfer, and that the geometry of these tiny tubes plays a role, especially when the flow isn’t too wild.

More importantly, our CFD work, armed with a new mass transfer model, helped us visualize and understand the tricky business of how a non-azeotropic mixture like R448A boils. The preferential boiling of certain components and the resulting mass transfer resistance near the wall are key phenomena that engineers need to consider when designing systems with these next-generation refrigerants.

This kind of detailed understanding is what helps us push the boundaries of cooling technology, making systems more efficient, more compact, and kinder to our planet. It’s a complex puzzle, but piece by piece, we’re figuring it out!

Source: Springer