Pump Priming Secrets: How Installation Height Tanks Performance

Hey there! Ever wondered how those clever pumps that don’t need you to manually fill them with water actually get going? We’re talking about self-priming pumps! These are the workhorses you find everywhere – from keeping fields watered in agriculture to tackling emergencies like firefighting or handling tricky fluids in chemical plants. They’re super handy because they can start pumping even if there’s air in the suction line, pulling the liquid up themselves.

Now, because these pumps are used in all sorts of places, they need to be tough and reliable. But getting that initial “self-priming” phase right can be a bit of a puzzle. It’s all about mixing air and liquid, separating them, and pushing the air out until only liquid is flowing. Once that’s done, they just hum along like a regular pump.

Researchers have been digging into how to make this process better for ages. They’ve looked at all sorts of things, like the shape of internal parts or how the liquid flows back inside. And these days, we’ve got some seriously cool tools to help us figure things out without even building a physical pump first. That’s where numerical simulation, especially something called Computational Fluid Dynamics (CFD), comes in. It lets us peer inside the pump and see exactly what the fluid is doing under different conditions.

But, and this is a big “but,” a lot of previous simulations simplified things a bit too much. They might only look at the pump itself, or they’d just *assume* how the air and water were distributed to start. They often skipped the crucial moment when the pump first starts and speeds up. We thought, “Hold on, the real world isn’t that simple!”

Our Approach: Simulating the Whole Shebang

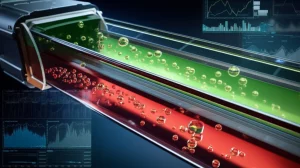

So, we decided to take a more realistic approach. Instead of just simulating the pump, we built a virtual model of the *entire system*. Imagine a digital twin of the pump, the pipes leading to and from it, the valves, and even the water tank with air sitting above the water – just like you’d find it in a real setup. We used a specific simulation method called Volume of Fluid (VOF), which is great for tracking how air and water mix and separate.

Crucially, we also included the pump’s startup phase. We simulated the impeller (that’s the spinning part inside) accelerating from a standstill up to its full speed, and then running steadily. We controlled this using a clever little piece of code called a User-Defined Function (UDF). This gave us a much more accurate picture of the *entire* self-priming process from the moment you flip the switch.

We wanted to see how one specific factor changed things: the installation height. That’s the vertical distance between the water level in the tank and the pump. We set up simulations for two different heights to see the impact.

Before we got too excited about our findings, we did our homework. We compared our simulation results for a normal pump operation (just pumping water) with real-world experiments, and they matched up really well. We also validated our self-priming simulation against visual experiments where we could actually *see* the water level rise in a transparent pipe. This gave us confidence that our virtual setup was behaving like the real deal.

The Big Reveal: Height Matters, A Lot!

Alright, let’s get to the juicy part. We ran our simulations for two different installation heights: 0.5 meters and 1.0 meters. The main thing we looked at was how long it took for the pump to become fully primed – meaning the entire pump cavity was filled with liquid and the air was expelled. And the difference was staggering!

When we increased the installation height from 0.5 meters to 1.0 meters, the self-priming time shot up by a whopping 6.260 seconds. Now, that might not sound like much on its own, but relatively speaking, that’s an 82% increase! Imagine waiting over 80% longer just because the pump is installed a bit higher. This clearly shows that installation height isn’t just a minor detail; it’s a critical factor affecting how quickly and efficiently a self-priming pump can do its job.

Peeking Inside: Gas and Liquid Dynamics

To understand *why* this happens, we looked at what was going on inside the pump during the self-priming process. We tracked the amount of air (the gas volume fraction) in different parts of the pump over time. We saw how the air gets drawn in, mixed with liquid, and then pushed out.

- In the S-pipe (the inlet section), increasing the height meant it took longer for the liquid from the tank to reach the pipe entrance and longer to push the air out. The peak amount of air in the S-pipe was also slightly higher at the greater height.

- Inside the impeller (the spinning heart of the pump), the gas started entering a little later at the higher height, the peak amount of gas was higher, and it took longer for the gas to be completely expelled.

- Even in the volute (the casing around the impeller), gas entered later and took longer to clear out at the higher installation height. Interestingly, during the phase where the pump is trying to push air out in bursts, the amount of air in the volute was always less than in the impeller chamber. This is because there’s some liquid clinging to the volute walls and also liquid coming back in from the separation chamber through a special hole (the reflux hole).

- The gas-liquid separation chamber, where the air and liquid are supposed to separate, also took significantly longer to clear out the air at the higher installation height.

Basically, at the higher installation height, the pump has to work harder against gravity to pull the liquid up and push the air out. This makes the whole process slower and less efficient in getting rid of the gas.

We also looked at the rate at which air was entering and leaving the pump. At the higher installation height, the rate of air coming into the pump inlet decreased more slowly after the initial rush, and it took longer for it to drop to zero. At the outlet, the average rate of air discharge was noticeably lower during the key phases when the pump is trying to expel air. This confirms that the higher height reduces the pump’s ability to efficiently move both air *in* and *out* during priming.

Understanding the Chaos: Vortices and Energy Loss

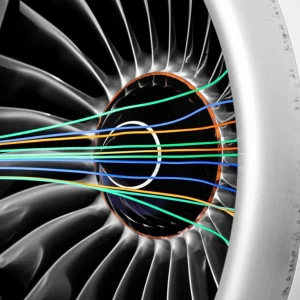

Beyond just tracking air and water, we wanted to understand the *energy* dynamics inside the pump. When fluids flow, especially when they’re mixing like air and water, things can get turbulent. This turbulence creates swirling patterns called vortices and leads to wasted energy, which scientists measure using something called entropy production.

We used methods to identify where these vortices were forming and where entropy production was high. What did we find?

- Even during the initial startup, we saw lots of vortices forming, especially where the air first hits the impeller and around the outer edge of the impeller where it meets the volute. These areas are clearly hotspots for energy loss.

- As the self-priming process continued, the distribution of vortices and high entropy production areas changed depending on how much air and water was in different parts of the pump.

- Crucially, we consistently saw significant energy losses concentrated at the impeller inlet, the outer edge of the impeller, and near the volute tongue (that pointy part of the volute where the flow starts to expand). These are the places where the fluid flow is most chaotic and energy is being wasted.

- In the later stages, when the impeller and volute were mostly filled with liquid, we saw very high entropy production right at the impeller inlet. This is likely due to the sudden change in flow direction and the liquid hitting the back of the impeller blades.

- Comparing the two installation heights, we observed that the lower height (0.5m) often showed more intense vortex activity and higher entropy production *at specific moments*, especially in the later stages. This might seem counterintuitive, but it’s likely because the self-priming process was happening *faster* at the lower height, leading to higher liquid velocities and more intense turbulence during those rapid changes. However, the *total time* to prime was much shorter.

- We also noticed that some air tended to get stuck in the rear pump chamber, which is tough to get out because there’s no direct outlet there and the centrifugal force on the gas is weak.

Putting It All Together

So, what’s the big takeaway from all this simulation work? It’s pretty clear: the installation height of a self-priming pump has a really significant impact on how well and how quickly it can prime itself. Installing the pump higher means it takes considerably longer to get rid of the air and start pumping liquid effectively.

Our detailed look inside showed *why* this happens – higher heights make it harder to draw air in and push it out efficiently, leading to a slower process overall. We also pinpointed the key areas inside the pump where energy is lost due to turbulent mixing and complex flow patterns, like the impeller inlet, the impeller outer edge, and the volute tongue. Understanding these loss hotspots could be super valuable for engineers looking to design even better, more efficient self-priming pumps in the future.

This study isn’t just academic; it offers practical guidance. If you’re installing a self-priming pump, keeping the installation height as low as possible relative to the liquid source is going to make a big difference in its performance and how quickly it gets the job done. It helps us understand the challenges and optimize designs and operations to improve efficiency and save energy in real-world applications.

Source: Springer