Sleeping Smarter: Our Deep Dive into Mattresses That Keep You Cool

Why Your Mattress Temperature Matters More Than You Think

Okay, let’s be real. We all know sleep is super important, right? It’s our body’s and brain’s reset button. But did you know that how hot or cold your mattress gets can seriously mess with your sleep quality? It’s true! Feeling too warm or too cool can lead to tossing and turning, and over time, that adds up. We’re talking potential links to all sorts of issues, from feeling foggy during the day to more serious long-term health stuff. So, finding a mattress that helps you stay just right temperature-wise? That’s a big deal for feeling good and staying healthy.

Enter the Game Changer: Phase Change Materials (PCMs)

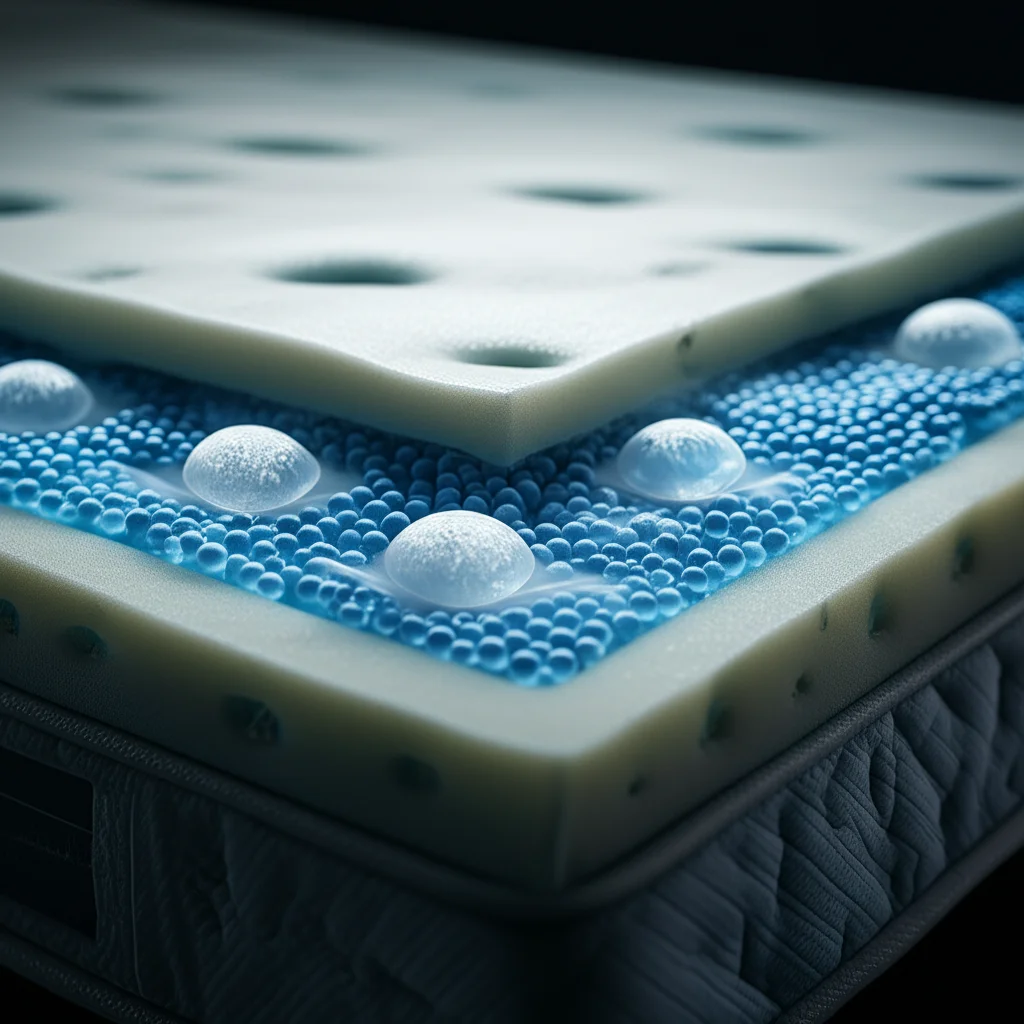

For ages, mattresses have been pretty basic when it comes to temperature. Some foams can even trap heat, making you feel like you’re sleeping in a warm hug you didn’t ask for. But what if your mattress could actively help manage your temperature? That’s where Phase Change Materials, or PCMs, come in. Think of them like tiny little thermal batteries. They can absorb heat when you get too warm, storing it away, and then release it back if things cool down too much. It’s a clever way to keep the surface temperature more stable and comfortable.

We’ve seen PCMs used in other cool ways – like in special clothing or building materials – but integrating them effectively into something squishy and supportive like mattress foam? That’s where the real challenge and excitement lie. Previous studies have shown promise, mixing PCMs into foams, but we wanted to take a really close look at how different types of foam, adding PCMs, and even adding ventilation would *really* perform under conditions that mimic you sleeping.

Our Mission: Finding the Coolest Combo

Our goal was pretty straightforward but super important: figure out the best way to use PCMs in polyurethane foam mattresses to keep things cool and comfortable. We weren’t just guessing; we set up a proper experiment to test different scenarios. We looked at:

- Standard polyurethane foam (what we called Low-Density Foam, or LDF)

- Denser foam (High-Density Foam, or HDF)

- Both types of foam *with* PCMs added

- Both types of foam *with* ventilation holes

- And, the ultimate test, both types *with* both PCMs *and* ventilation holes!

That gave us eight different mattress setups to compare side-by-side. We wanted to see which combination was the champion of temperature regulation.

Setting Up Our Thermal Playground

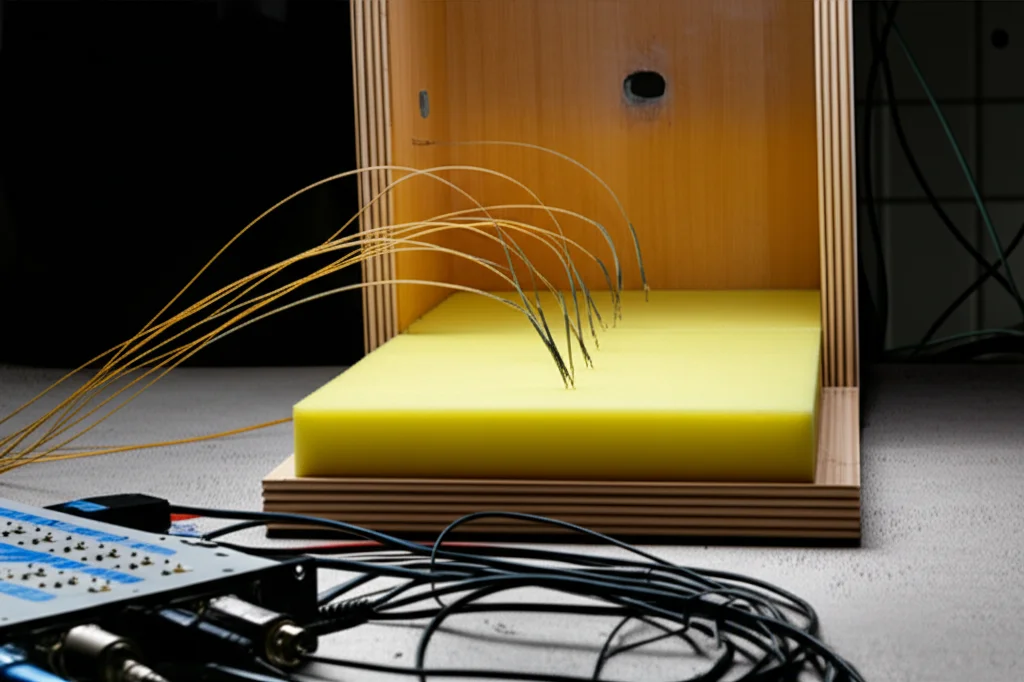

To do this right, we built a controlled testing environment. Imagine a wooden box, kind of like a mini-mattress chamber. Inside, we layered up our foam samples. To simulate the heat a human body gives off while sleeping, we used incandescent light bulbs. Why bulbs? Because they put out heat in a way that’s pretty similar to our resting metabolic rate – around 114 Watts, which is right in the ballpark of what a person generates. We placed these bulbs carefully to spread the heat evenly across the surface, just like your body heat would.

Measuring the temperature accurately was key. We used special temperature sensors called T-type thermocouples. We stuck them at different depths within the foam layers – top, middle, and bottom – and also monitored the ambient (room) temperature. These sensors were hooked up to a fancy data acquisition (DAQ) system that recorded the temperatures constantly. This gave us a real-time picture of how heat was moving and building up (or not building up!) in each mattress configuration over several hours.

We also paid close attention to making sure our measurements were reliable. We did all the necessary calibration for our thermocouples and performed an uncertainty analysis. This sounds technical, but it just means we checked how much potential error there might be in our readings and confirmed that our setup was accurate enough to trust the results – our total measurement uncertainty was really low, less than 5%.

Choosing Our PCM Champion

Now, about the PCM itself. There are different types out there. We chose Sodium Carbonate Decahydrate (SCD). Why SCD? Well, it’s a bit of a superstar in the PCM world for this kind of application. It has a really high latent heat capacity – meaning it can soak up a lot of heat as it changes phase (melts). Its phase change temperature is also just about perfect for body temperature, around 32°C. Plus, it conducts heat pretty well, which helps it absorb and release heat efficiently. And, importantly, it’s quite cost-effective compared to some other options like paraffin wax, which doesn’t store as much heat and isn’t as good at moving it around.

We packaged the SCD into little 100-gram pouches and placed them strategically within the foam layers in our test chamber. This setup mimicked how PCMs might be integrated into a real mattress.

Putting the Mattresses to the Test

The experiment involved turning on our heat source (the bulbs) and letting it run for several hours. We gave the setup about 30 minutes to stabilize before we started recording data. We did this for each of the eight configurations – foam alone (LDF and HDF), foam with PCM, foam with holes, and foam with both. By recording the temperatures in the different layers over time, we could see how well each setup managed the heat.

To figure out the temperature for each layer (top, middle, bottom), we averaged the readings from the three thermocouples placed in that layer. This gave us a clear picture of the temperature profile within the mattress sample. We then plotted these temperatures over time to visualize the thermal performance.

The Results Are In: And There’s a Clear Winner!

After crunching the numbers and looking at the graphs, some configurations definitely stood out. We focused on the temperature difference (ΔT) between the ambient room temperature and the top layer of the mattress after the heating had been going for a while. A bigger ΔT means the mattress surface stayed cooler relative to the heat source, indicating better thermal regulation.

- Just HDF foam? Not great at controlling heat.

- Just LDF foam? A little better than HDF, but still got warm.

- HDF with PCM? Much better! The PCM helped absorb heat and keep the surface temperature more stable.

- LDF with PCM? This was the star performer! It showed the biggest temperature difference, meaning the top surface stayed significantly cooler. The combination of the lighter foam structure and the PCM’s heat absorption really worked wonders.

What about the ventilation holes? We added holes to some samples thinking they’d help airflow and dissipate heat. And they did help a little, improving performance compared to foam without holes. But here’s the key takeaway: ventilation alone wasn’t nearly as effective as adding PCMs. The configurations with PCM, even without holes, performed much better than those with holes but no PCM.

The combination of LDF with both holes and PCM also performed well, showing the benefits of both, but the PCM was clearly the dominant factor in achieving superior thermal regulation. Our statistical analysis (the ANOVA test we mentioned) confirmed this big time – the differences we saw between the configurations, especially those with and without PCM, were statistically significant. This wasn’t just random chance; the materials and design choices *mattered*.

What This Means for Your Sleep

So, what’s the big picture here? This study strongly suggests that putting PCMs into polyurethane foam mattresses is a fantastic way to improve thermal comfort. Specifically, using Sodium Carbonate Decahydrate in a low-density foam structure seems to be a really effective and potentially cost-effective way to go. We saw a temperature reduction of over 7°C on the top layer with the LDF + PCM setup compared to ambient conditions – that’s a noticeable difference for anyone who sleeps warm!

While our experiment was done in a controlled lab setting (real-world sleeping involves more variables like movement, humidity, and body weight distribution), the findings give us a solid foundation. They show the incredible potential of PCM technology to make mattresses smarter and more comfortable, helping you stay in that sweet spot temperature-wise all night long.

Ultimately, this research is a step forward in sleep technology. It shows that we can design mattresses that don’t just support your body but also actively manage your temperature, leading to better, more restful sleep. And who doesn’t want that?

Source: Springer