Unlock Peak QLED Performance with Operando ZnO Recrystallization

Hey everyone! Let me tell you about something pretty cool happening in the world of displays. You know those gorgeous, vibrant QLED screens? Well, scientists are always pushing to make them even better, brighter, and more efficient. And guess what? A big part of that puzzle involves a material called Zinc Oxide, or ZnO.

The Problem with Our Electron Highway

So, ZnO nanoparticles (NPs) are like the tiny little highways for electrons in QLEDs, helping them get where they need to go to make light. They’re usually pretty good at transporting electrons. But, and this is a big but, there was a hidden snag. Turns out, having *too many* charge carriers packed into the ZnO can cause a problem called Auger recombination right where the quantum dots (the light-makers) meet the ZnO. Think of it like a traffic jam causing collisions instead of smooth sailing. This traffic jam actually *reduces* the efficiency of the light emission.

What we really needed was an electron transport layer (ETL) that’s super speedy (high mobility) but doesn’t have a crazy high density of charge carriers causing all that trouble. It’s a bit of a balancing act, right? High conductivity usually means high density *or* high mobility. We needed the latter.

Witnessing the Transformation: Operando Recrystallization

Here’s where things get really interesting. We stumbled upon a way to achieve this ideal balance through a process we’re calling operando recrystallization. “Operando” basically means it happens while the device is doing its thing, or in this case, just sitting there after fabrication under specific conditions.

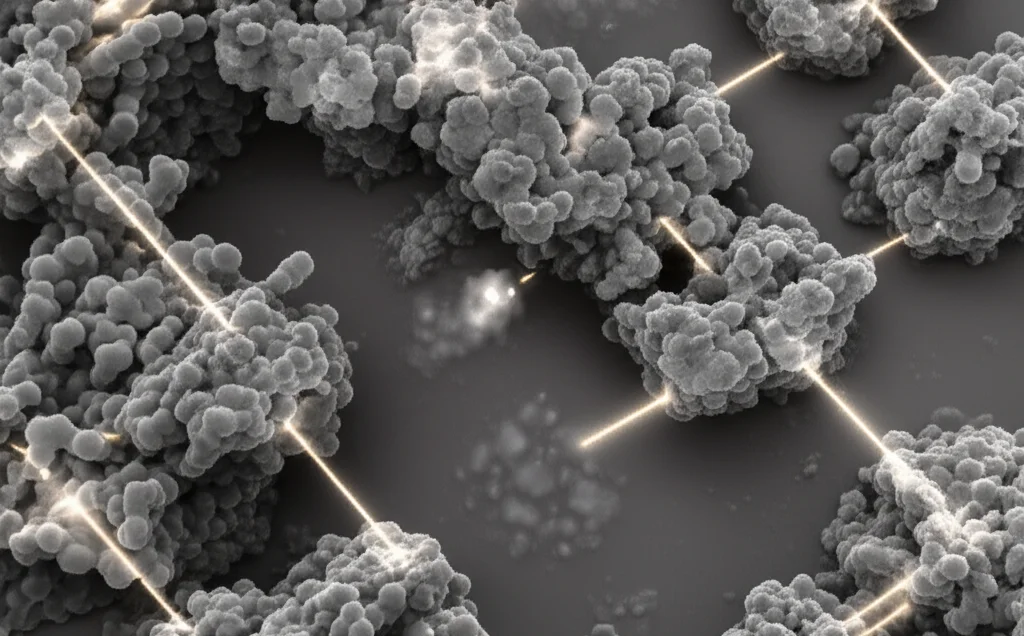

What triggers this magical transformation? It’s all about the diffusion of aluminum (Al) ions from the cathode (that’s one of the electrodes in the device) under slightly acidic conditions. As these Al ions wander into the ZnO NP film, they actually cause the neighboring ZnO nanoparticles to start merging, or *coalescing*.

This isn’t just random clumping. It forms larger, more ordered ZnO crystals. And here’s the crucial part: this recrystallization process helps to *passivate* defects in the ZnO structure. Think of defects as potholes on our electron highway. Filling those potholes makes the road smoother.

The Payoff: Supercharged QLED Efficiency

The result of this operando recrystallization is pretty dramatic. When we used this recrystallized ZnO as the electron transport layer in QLEDs, the performance jumped significantly. We saw the external quantum efficiency (EQE) — which is a key measure of how efficiently the device converts electricity into light — shoot up from a respectable 17.2% to an incredible 33.7%! That’s a massive improvement, basically doubling the efficiency compared to devices using the standard, non-recrystallized ZnO.

This wasn’t just a fluke. We saw this “positive ageing” effect, where the device performance actually *improved* over time when stored under specific conditions (acidic environment, active metal cathode like Al or Ag). This positive ageing phenomenon, which scientists had observed before but didn’t fully understand, is now explained by this operando recrystallization process.

Digging Deeper: How It Works

We did a bunch of tests to figure out exactly what was going on. We looked at:

- Current-Voltage-Luminance (J-V-L) and EQE: These showed the clear performance boost and how the luminance increased much more than the current, indicating better light generation, not just more current flowing.

- Electron Transport Properties: Using special devices, we saw that the acid-treated, aged ZnO had significantly fewer electron traps (those pesky potholes!) compared to the original ZnO.

- Electron Mobility: This was a big one! Measurements showed that the electron mobility in the recrystallized ZnO was *orders of magnitude* higher than before. This means electrons can zip through the layer much faster and more efficiently. While carrier density *decreased* (which you’d normally think would lower conductivity), the huge boost in mobility more than compensated, leading to better overall transport *and* reduced Auger recombination.

- Defect Passivation: Techniques like XPS and PL spectroscopy confirmed that the Al ions, especially under acidic conditions, were effectively filling in defects in the ZnO structure.

- Structural Changes: XRD analysis showed that the crystal structure of the ZnO was enhanced, specifically growing along a certain direction. TEM and high-resolution TEM images gave us a visual confirmation – we saw the individual nanoparticles merging into larger, continuous nanocrystals.

- Charge Carrier Dynamics: We looked at how electrons behaved in the quantum dots when in contact with the recrystallized ZnO. The passivated ZnO layer did a much better job of protecting the quantum dots from quenching (losing their energy non-radiatively), allowing them to emit light more effectively.

It turns out that the Al ions substitute into the ZnO lattice, forming strong bonds and stabilizing the structure. The acidic conditions also help by promoting dehydration reactions between hydroxyl groups on the ZnO surface, further encouraging the nanoparticles to link up and form those larger crystals. It’s like the Al and acid work together to help the little ZnO particles hold hands and form bigger, stronger teams.

Why This Matters

This finding is a pretty big deal! It shows that the electron transport in the recrystallized ZnO shifts from a slower “hopping” mechanism (like electrons jumping between isolated islands) to a faster, more efficient “band-like” conduction (like electrons flowing freely in a continuous material).

This improved transport means electrons are injected into the quantum dots in a much more controlled, “injection-on-demand” way. Instead of flooding the area and causing traffic jams (Auger recombination), electrons arrive efficiently when needed to form excitons (the light-emitting pairs). This dynamic charge balance is key to achieving higher efficiency.

Beyond just QLEDs, ZnO is used in lots of other cool devices like perovskite solar cells and organic LEDs. So, this idea of using operando engineering – triggering changes in the material *after* it’s put into the device – could be a powerful way to fine-tune the properties of nanocrystals with active surfaces for all sorts of high-performance optoelectronic applications.

It just goes to show that sometimes, the most exciting breakthroughs happen not just by creating new materials, but by finding clever ways to make the materials we already have work even better, right there inside the device!

Source: Springer