Eco-Friendly Clay Catalyst: Making Carvacryl Acetate Greener e Faster

Hey there! Let’s chat about something pretty cool happening in the world of chemistry. You know carvacrol, right? It’s that awesome compound found in things like oregano and thyme, famous for its anti-inflammatory and antibacterial powers. Well, scientists are always looking for ways to make even better versions of these natural goodies. And one compound that’s catching a lot of attention is carvacryl acetate.

Why Carvacryl Acetate?

Think of carvacryl acetate as carvacrol’s slightly more stable, potentially even more potent cousin. It seems to pack a similar punch when it comes to fighting inflammation, bacteria, and even pain, but with the added bonus of being less toxic and more stable than carvacrol itself. So, finding a good way to make it is a big deal for pharmaceuticals and other industries.

The Old Way: A Bit Messy

Traditionally, making carvacryl acetate involves reacting carvacrol with stuff like acetyl chloride or acetic anhydride. This usually happens with what we call “homogeneous” catalysts – basically, catalysts that dissolve right into your reaction mixture. While this works, it’s got downsides. First, if you use acetyl chloride, you end up with a fair bit of chlorinated waste, which is definitely not great for the environment. Second, and this is a big one, separating the dissolved catalyst from your final product can be a real headache. Imagine trying to filter out something that’s completely mixed in – it’s tricky and often requires extra steps and solvents, adding to the waste and cost.

Enter Montmorillonite: Our Earthy Hero!

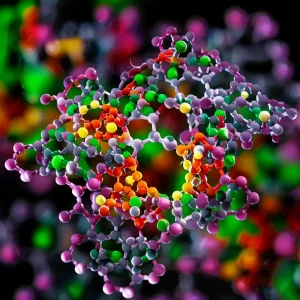

This is where things get exciting! What if we could use something cheap, readily available, and totally eco-friendly as a catalyst? Something that *doesn’t* dissolve, making it super easy to separate? That’s where montmorillonite comes in. It’s a type of clay, a natural alumosilicate mineral, and it’s got this fantastic layered structure with acidic properties. These acidic sites are key because they can help speed up chemical reactions, like the one we need to make carvacryl acetate.

Montmorillonite is already known for being a useful catalyst in various reactions, but using it for this specific carvacrol esterification with acetic anhydride, especially without any solvent? That wasn’t really a common thing. And let me tell you, finding a solvent-free, eco-friendly alternative to those traditional methods is a huge win for green chemistry.

Boosting the Clay’s Power

While natural montmorillonite (like the commercially available K10 type) is pretty good, you can make it even better. How? By treating it with acids! In this work, they took montmorillonite K10 and treated it with either nitric acid or sulfuric acid. This acid treatment does some neat things to the clay’s structure, primarily boosting its acidity by creating more acidic sites, especially stronger ones. Think of it like giving the clay catalyst a power-up!

They did a bunch of tests to really understand these acid-treated clays. They looked at their structure (using things like XRD and FTIR), their composition (XRF and elemental analysis), their surface area and pore structure (nitrogen physisorption), how acidic they were and what *kind* of acid sites they had (temperature programmed desorption of pyridine and DR-UV-Vis), and even the size of the clay particles (laser light scattering). All these tests basically confirmed that the acid treatment successfully increased the acidity without messing up the fundamental clay structure too much, making them ready for action.

Our Experiments and Amazing Results

So, we (well, the researchers whose work this is!) set up the reaction: carvacrol plus acetic anhydride, at room temperature, with no solvent, and added a small amount of our catalyst – either the commercial montmorillonite or one of the acid-treated versions. And the difference was night and day!

- Without any catalyst, the reaction was super slow. We’re talking only 5% conversion after 30 minutes.

- Using the commercial montmorillonite K10 sped things up a lot – 93% conversion in an hour. Much better!

- But the real stars were the acid-treated montmorillonites (MMT-H2SO4 and MMT-HNO3). Using just a small amount (3.75% by weight relative to carvacrol), they achieved *total* carvacrol conversion in a mind-blowing 10-15 minutes! And get this: the selectivity to the desired carvacryl acetate was 100% in all cases. No unwanted byproducts!

They even checked what happens if you use *more* catalyst. With 5% of the sulfuric acid-treated montmorillonite, total conversion happened in just 3 minutes! Talk about fast!

Digging Deeper: Why It Works So Well

The increased activity of the acid-treated clays directly correlated with their increased acidity, especially the formation of new, stronger acid sites. The studies showed that the dominant acidic sites were Brønsted acid sites (basically, sites that can donate a proton), which are crucial for this type of esterification reaction.

They also looked into the reaction kinetics – how fast the reaction proceeds and what factors influence it. Interestingly, the acetic acid that’s produced during the reaction didn’t seem to act as a catalyst itself under these mild conditions. This is likely because carvacrol isn’t a simple primary alcohol, and phenolic compounds like carvacrol don’t easily esterify with carboxylic acids under mild conditions like these. This confirms that the clay catalyst is doing all the heavy lifting.

They did notice some catalyst deactivation over time, especially with lower catalyst amounts. This could be due to things sticking to the catalyst surface or the catalyst running out of protons as acetic acid is formed. But even with this, the treated catalysts were incredibly effective for rapid conversion.

The Big Picture: Greener, Faster, Better

What this all means is that acid-treated montmorillonite clay is a seriously promising catalyst for making carvacryl acetate. It offers a fantastic environmentally friendly alternative to older methods. It’s cheap, it works without needing any solvents, it’s incredibly fast, and it gives you a pure product with 100% selectivity. Plus, because it’s a solid (heterogeneous) catalyst, separating it from the liquid product is simple – just filter it out!

Developing efficient, green ways to synthesize valuable compounds like carvacryl acetate is super important. This work shows that something as simple and abundant as clay, with a little acid treatment, can be a powerful tool in making chemistry cleaner and more efficient. It’s exciting to see how natural materials can be harnessed for modern chemical processes!

Source: Springer