Bugs to the Rescue: Healing Desert Channels with Microbial Magic

Hey there! Fixing Cracks in the Desert

So, imagine you’ve got these crucial water channels cutting right through a seriously tough place – the Xinjiang desert. These aren’t just ditches; they’re lifelines, bringing water where it’s desperately needed. But the desert is harsh, right? Think scorching heat, then maybe freezing nights, water levels going up and down… all that environmental stress really takes a toll on the concrete lining of these channels. It cracks. And when it cracks, water seeps out into the sandy soil, messing everything up, potentially even causing the banks to collapse. Not good for keeping that precious water flowing!

Traditionally, fixing these kinds of cracks means using stuff like epoxy or grout. They work, sure, but sometimes they’re not the most eco-friendly, can be a bit energy-hungry to apply, and might not play nice with the existing concrete long-term. I mean, we’re looking for something sustainable, something that fits the environment.

Enter the Microbes: A Natural Fix?

That’s where this really cool idea comes in: using microbes – tiny bacteria – to do the repair work for us. It’s called Microbially Induced Calcium Carbonate Precipitation, or MICP for short. The basic gist? Certain bacteria, like the Sporosarcina pasteurii strain we looked at, can basically create tiny little mineral crystals, specifically calcium carbonate (think of it like natural cement or limestone), right inside the cracks. They do this through their normal life processes, like breaking down urea. This process is super appealing because it’s energy-saving, environmentally friendly, and doesn’t require ripping things apart.

People have already seen how well MICP can work in desert sands, stabilizing things. So, the big question was, could it work just as well for fixing concrete cracks in these vital desert channels?

Putting the Microbes to Work: Our Experiment

We wanted to see if this bug-powered repair trick could handle the job on concrete cracks specifically. Since testing directly on a real, massive desert channel is a bit tricky (cracks are all over the place and irregular), we decided to bring the problem into the lab in a controlled way. We made concrete cylinder specimens, kind of like mini sections of the channel lining, and intentionally created cracks of different widths, ranging from super thin (0.1 mm) to quite wide (5.0 mm).

Then came the microbial repair part. We used the ‘passive repair’ method, which means we injected our special bacterial solution, along with the necessary nutrients (like calcium sources), directly into these prefabricated cracks. We did this repeatedly – 16 cycles in total, once a day for 16 days. This is different from ‘self-healing’ concrete where the bugs are mixed in from the start; here, we’re fixing existing damage.

After the 16 cycles, we needed to figure out how well it actually worked. We didn’t just eyeball it! We got serious with our evaluation, looking at both the big picture (macroscopic) and the tiny details (microscopic).

Measuring Success: Area, Water Flow, and Soaking

On the macroscopic side, we measured a few key things:

- Area Repair Rate: We took pictures of the cracks before and after the 16 repair cycles and used image analysis to see how much of the crack area got filled in. This gives us a visual idea of the repair progress.

- Penetration Resistance (Permeability): This is crucial for a water channel! We tested how much water could seep through the repaired cracks under pressure. A lower permeability coefficient means the repair is doing its job blocking water. We compared this to the original cracked state and intact concrete.

- Capillary Water Absorption: Concrete can soak up water like a sponge through tiny pores (capillary action). We measured how much water the repaired specimens absorbed over time. Reducing this absorption means the repair is making the concrete more waterproof.

To really understand *what* was happening inside the cracks, we also used microscopic techniques:

- XRD (X-ray Diffraction): This tells us the chemical composition of the material that formed inside the cracks. We expected to see a lot of calcium carbonate!

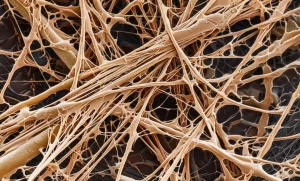

- SEM (Scanning Electron Microscopy): This gives us super high-resolution images of the repair material, showing its structure and how well it’s bonding with the concrete.

The Big Reveal: It Works, But There’s a Sweet Spot!

After all the testing, the results were pretty clear and exciting! MICP technology definitely works for repairing these concrete cracks. The microscopic tests confirmed that yes, a lot of calcium carbonate (calcite, specifically) was forming inside the cracks, filling them up and bonding nicely with the concrete. This is why we saw significant improvements in how much water could get through (permeability) and how much water the concrete soaked up (water absorption).

For the narrower cracks, say between 0.1 mm and 0.8 mm, the microbial repair was incredibly effective. After 16 cycles, the cracks were almost completely sealed, with an area repair rate close to 100%. The permeability reduction was dramatic – we’re talking a recovery rate of 99.4% or even higher! The waterproofing also improved significantly.

However, here’s the key finding: as the crack width increased, the repair efficiency started to drop off. For cracks 1.0 mm wide, the area repair rate after 16 cycles was still decent at around 93.6%, and the permeability was still greatly reduced (similar to the narrower cracks, about three orders of magnitude reduction compared to unrepaired cracks). But for cracks wider than that, the repair rate plummeted. A 1.5 mm crack only got about 43.2% filled, and anything over 2.0 mm barely showed any significant area repair (less than 10%).

The permeability and water absorption results mirrored this trend. While wider cracks (up to 2.0 mm) still saw a big drop in permeability compared to being unrepaired, the effectiveness decreased significantly for cracks wider than 2.0 mm. The water absorption tests also showed a sharp decline in repair effectiveness for cracks exceeding 1.0 mm.

Why the 1.0 mm Limit?

So, why does this microbial magic work so well on narrow cracks but struggle with wider ones within the same number of repair cycles? Think of it like trying to build a bridge. In a narrow gap, the calcium carbonate particles precipitated by the bacteria can easily bridge the space and build up a dense, continuous layer. There’s less distance for the microbes and nutrients to travel, and the physical constraints of the narrow crack help guide the precipitation and make it stick together tightly.

In wider cracks, it’s a different story. The microbes and their metabolites have to travel further. The calcium carbonate tends to settle more at the bottom due to gravity and might form looser connections in the middle. It’s harder to build that continuous, dense barrier layer needed for full sealing and waterproofing. Under water pressure, these looser formations in wider cracks are more vulnerable to being washed away or damaged.

Based on all these results – the area repair rate, the permeability reduction, and the improved waterproofing – we concluded that for a 16-cycle repair process using this specific MICP method, a crack width of 1.0 mm is pretty much the optimal threshold. It gives you the best balance of structural filling and, crucially for a water channel, excellent waterproofing and impermeability without needing excessively long repair times.

Looking Ahead: What About Wider Cracks?

Does this mean MICP is only for small cracks? Not necessarily! The study suggests that for cracks wider than this optimal threshold (1.0 mm for 16 cycles), you might need a different approach. One promising idea mentioned is combining MICP with local materials, like the aeolian soil from the desert itself, to act as an aggregate or filler in the wider cracks before applying the microbial treatment. This could help fill the larger volume, make the repair material more compatible with the environment, potentially reduce costs, and improve efficiency for those bigger gaps.

This research provides valuable insights specifically for fixing those tricky lining cracks in Xinjiang’s desert water channels. While the optimal width might vary slightly depending on the specific concrete and environmental conditions of other projects, the methodology used here – combining macroscopic performance tests with microscopic analysis – offers a solid blueprint for evaluating and applying MICP technology in similar challenging environments. It’s all about finding the right balance and potentially combining this cool bio-technique with other methods for the best results.

Source: Springer