Our Magnetic Palladium Catalyst: Making Isatin Synthesis Greener and Easier!

Hey there! Let’s chat about something pretty cool happening in the world of chemistry. For the last couple of decades, folks like me (well, the collective “me” of the scientific community!) have been really pushing hard for chemistry that’s, you know, *nicer* to the planet. We’re talking about cutting down on nasty chemicals, making reactions less dangerous, and generally simplifying the whole process. It’s all about sustainable chemistry, and a big piece of that puzzle is finding better catalysts.

Why Catalysts Matter (and the Problem with Old Ones)

Think of a catalyst as a helpful friend who speeds up a chemical reaction without getting used up themselves. They make things happen faster and often with less energy. Historically, we’ve used what are called “homogeneous” catalysts. These are dissolved right in the reaction liquid. The upside? They can be super efficient because they’re mixed in everywhere. The downside? Trying to fish them back out of the reaction mixture afterward can be a real headache. And if they contain heavy metals (like palladium, which is awesome but needs careful handling), you definitely don’t want them hanging around in your final product or waste.

So, the big goal has been to create “heterogeneous” catalysts. These aren’t dissolved; they’re solid little particles. The dream is to keep their “active sites” (the spots where the magic happens) working just as well, but make them easy to separate. Imagine being able to just scoop or filter your catalyst out when the reaction is done. Much cleaner, much simpler!

Enter the Magnetic Marvel

This is where things get really interesting. What if you could make your heterogeneous catalyst *magnetic*? That’s right, just wave a magnet, and *poof*, your catalyst is separated! Magnetic supports for catalysts are gaining popularity because they’re generally less toxic, cheaper to make, have lots of surface area for reactions, and, most importantly, you can recover them super easily with an external magnet.

We’ve seen all sorts of things used to build these magnetic catalysts – from organic bits to biological compounds. These different materials help hold onto the metal (like palladium) that does the actual catalytic work. But figuring out exactly *how* the metal sits on these supports can be tricky.

Our Special Blend: Fe₃O₄@SiO₂-SD@Pd

Okay, deep breath for the name: Palladium-supported Fe₃O₄@SiO₂-functionalized methyl 2-(phenylthio) acetate. Let’s break it down a little. We start with magnetic iron oxide nanoparticles (Fe₃O₄). We coat them with silica (SiO₂) – think of it like a protective shell and a surface to build on. Then, we attach a specific organic molecule, methyl 2-(phenylthio) acetate (we called it SD for short in the lab chatter), which acts like a handle or anchor. Finally, we get the superstar palladium (Pd) to attach to this handle. So, it’s a magnetic core, a silica layer, an organic linker, and the palladium doing the heavy lifting. Pretty neat, right?

Why Are We Making Isatins?

Now, why bother making this specific catalyst? Well, we were focused on synthesizing a really important group of compounds called *Isatin derivatives*. These aren’t just random chemicals; they’re biological heavy hitters! They show promise for all sorts of therapeutic uses – anti-cancer, antiviral, antibacterial, and lots more. Making these compounds efficiently and sustainably is a big deal for drug discovery and chemical synthesis.

Specifically, we looked at making 5-styryl indoline-2,3-dione derivatives. Palladium is known to be fantastic for these kinds of reactions, particularly something called the *Heck reaction*, which is great for making carbon-carbon bonds in a sustainable way.

Putting Our Catalyst to the Test

We synthesized our Fe₃O₄@SiO₂-SD@Pd catalyst step-by-step. First, we made the magnetic core with the silica shell. Then, we attached the organic linker (SD). Finally, we added palladium acetate to get the palladium onto the support.

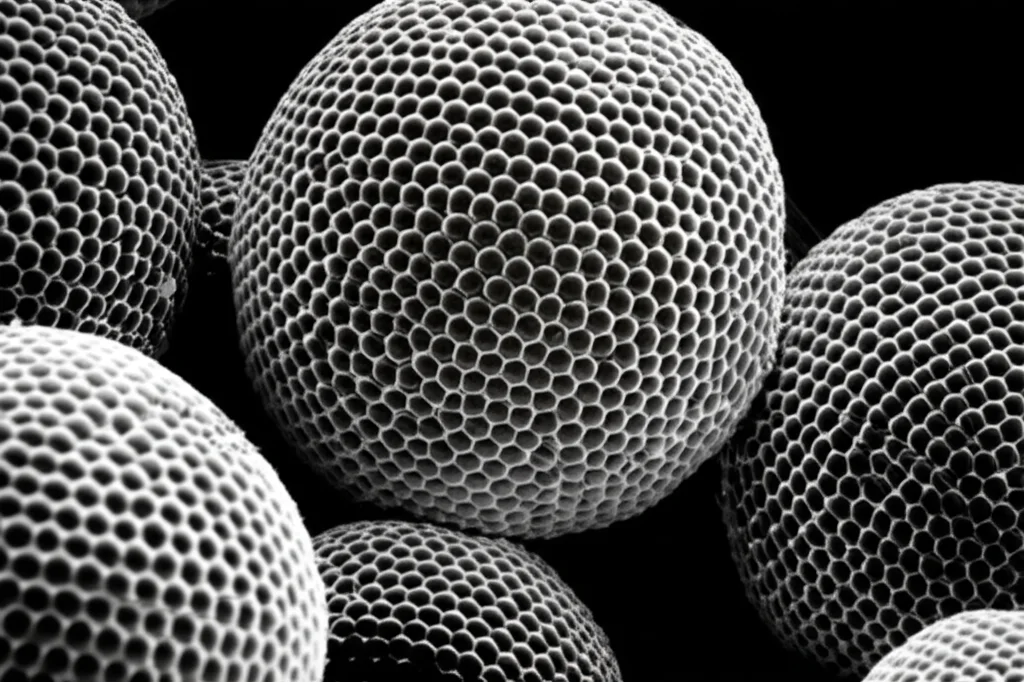

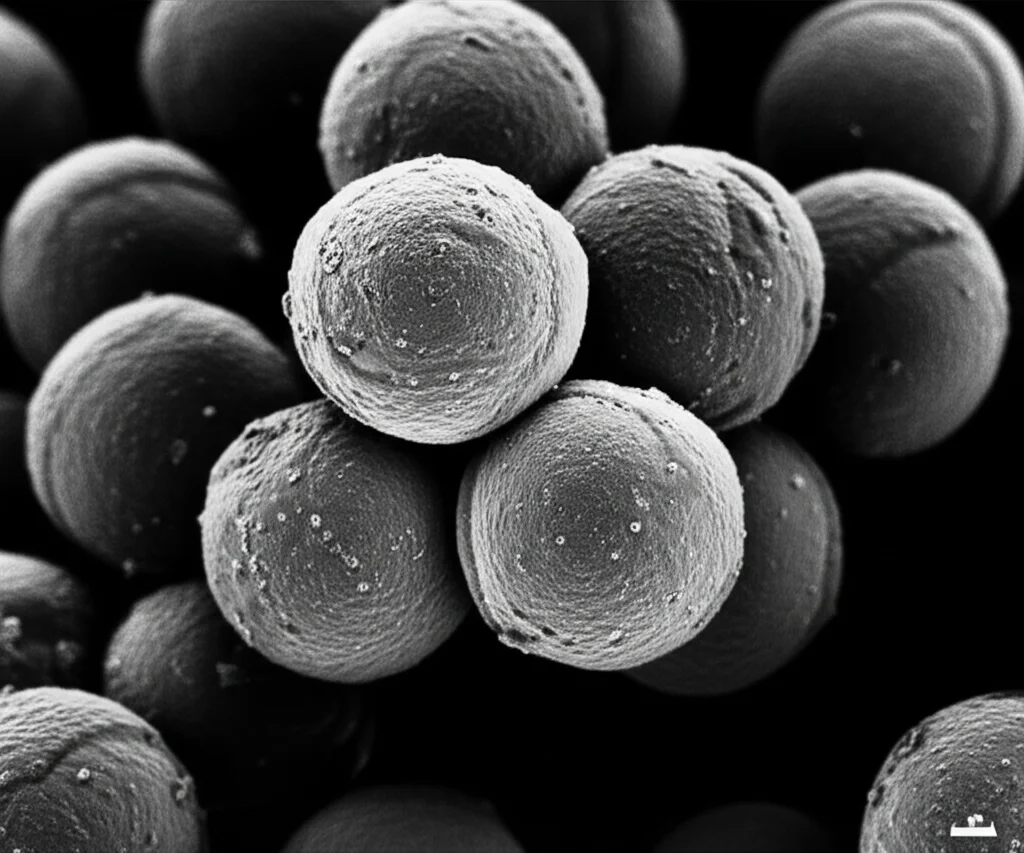

To make sure we actually made what we thought we did and to understand its properties, we threw the book at it with characterization techniques. We used things like FT-IR (to see which chemical groups were there), TGA (to see how much organic stuff was on it by burning it off), FE-SEM and TEM (to see what the particles looked like and how big they were – turns out they’re nice and spherical, around 40-57 nm!), VSM (to check its magnetic properties), EDS and ICP (to confirm the elements, especially the palladium content), and XRD (to see the crystal structure). All the tests basically confirmed our catalyst was built correctly and had the properties we wanted. It was magnetic, had the organic linker, and carried the palladium.

Then came the fun part: testing its catalytic power! We used a standard *Isatin Heck reaction* as our model – reacting a bromo-isatin derivative with styrene. We tried our catalyst alongside some components of it to see which was the active one (spoiler: our full Fe₃O₄@SiO₂-SD@Pd catalyst was the winner!).

We played around with the reaction conditions – temperature, base, and solvent. We found that a mix of DMF and water (8:3 ratio) with KOtBu as the base at 90°C gave us the best results. Interestingly, this temperature is lower than some previous reports for similar reactions, which is a win for energy saving! DMF, being a polar solvent, really helps stabilize things and speed up the Heck reaction. We also figured out the optimal tiny amount of catalyst needed – just 0.01 mmol got the job done beautifully, giving us high yields (between 78% and 88% for various Isatin derivatives).

Beyond the Basic Heck: Dual and Triple Challenges

Feeling confident, we decided to push our catalyst further. Could it handle more complex reactions? We tried a *dual Heck reaction* on a starting material with two bromine atoms that could react. Success! Our catalyst could make two new carbon-carbon bonds simultaneously. This shows its versatility for building more complex molecules.

Then, we got ambitious and tried a *triple Heck reaction* on a molecule with three potential reaction sites. This one threw us a curveball! Instead of just three Heck reactions, we found that two Heck reactions happened, *plus* a *C-H activation* reaction on a different part of the molecule. This was an unexpected but awesome discovery! It means our catalyst isn’t just good at one thing; it can perform different types of reactions (*orthogonal tandem catalysis*) in the same pot. It’s like a master conductor leading a complex symphony of chemical transformations!

We also explored *C-H activation* on other Isatin derivatives, looking at different positions on the molecule. It seems our catalyst is quite good at activating those tricky C-H bonds, especially within the same molecule (intramolecular activation).

Sustainable and Recyclable!

One of the biggest wins for a heterogeneous catalyst is its reusability. We put our Fe₃O₄@SiO₂-SD@Pd catalyst through the wringer, using it for five reaction cycles. And guess what? It kept its efficiency without significant loss! This is huge for making the process cost-effective and reducing waste.

How did we know the palladium wasn’t just leaking off the support into the solution (acting like a homogeneous catalyst)? We did a “hot filtration test.” We stopped the reaction partway through, separated the catalyst with a magnet while it was still hot, and let the liquid keep stirring. The reaction pretty much stopped, showing that the catalyst needed to be physically present to work. We also checked the liquid with ICP and found hardly any palladium had leached out.

We even did a “mercury poisoning test,” which is a classic way to check if palladium is working heterogeneously or if tiny bits are dissolving and doing the work homogeneously. Adding mercury gums up dissolved palladium. When we added mercury, the reaction yield dropped significantly, confirming that the reaction was indeed happening on the surface of our solid catalyst particles via a Pd(0)/Pd(+2) mechanism.

After using the catalyst multiple times, we checked its structure again using the same characterization techniques (FT-IR, XRD, SEM, TEM, etc.). Everything looked pretty much the same, confirming that the catalyst structure held up well during use.

How We Think It Works (The Mechanism)

Based on our findings and what’s known about these reactions, we proposed a mechanism for how our catalyst helps make these *arylated* products (like the styryl Isatins). It likely starts with the palladium on the catalyst surface reacting with the bromo-isatin (oxidative addition), then things rearrange, the palladium complex attacks the styrene, and finally, the product is formed, and the palladium goes back to its starting state on the catalyst surface, ready for the next cycle. It’s a bit like a molecular dance happening on the surface of our tiny magnetic spheres.

The Takeaway

So, what’s the big picture here? We’ve successfully developed a new, sustainable heterogeneous catalyst – Fe₃O₄@SiO₂-SD@Pd – that’s supported on magnetic nanoparticles. This catalyst is fantastic for synthesizing important *Isatin derivatives* through *Heck*, *C-H activation*, and *cycloaddition* reactions. It works efficiently under moderate conditions, gives good yields, and, crucially, it’s easy to separate using a magnet and can be reused multiple times without losing its punch.

This isn’t just a cool lab trick; it’s a step forward for green chemistry. By making these vital compounds using less toxic materials, easier separation, and reusable catalysts, we’re contributing to more sustainable and efficient chemical processes. Our magnetic little helper is truly a silent hero in the world of synthesis, capable of orchestrating complex chemical symphonies!

Source: Springer