Sniffing Out Danger: My Take on a Breakthrough Ethylene Glycol Sensor

Hey there! So, I was digging into some pretty neat scientific research the other day, and something really caught my eye. It’s all about making the world a bit safer, specifically by getting better at detecting something you might not think about much, but is actually quite hazardous: ethylene glycol.

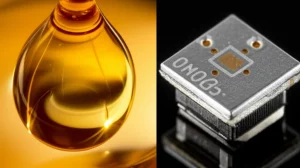

You know ethylene glycol, right? It’s that stuff often found in antifreeze. It’s super useful in lots of industries because of its properties, but here’s the kicker: it’s also highly toxic. And what makes it extra sneaky is that it’s colorless, odorless, and even has a sweet taste. Yeah, you heard that right – sweet! That makes accidental ingestion a real risk for both people and animals. While the stuff itself isn’t *instantly* lethal in small amounts, your body breaks it down into nasty things like glycolic and oxalic acids, which can seriously mess up your kidneys and other vital organs. Plus, spills are a big no-no for the environment, contaminating water and soil.

So, it’s pretty clear we need reliable ways to detect this stuff, especially if there’s a leak or a spill. And that’s where the cool science comes in.

The Challenge with Current Sensors

Now, we’ve got sensors out there, but many of the common ones, like those made from single-component metal oxides, have a bit of a problem. They’re not always the best at telling one gas apart from another. Imagine a sensor that reacts similarly to ethylene glycol, ethanol, and acetone. It’s like trying to identify a specific person in a crowded room just by their height – lots of people fit the bill! This lack of selectivity can lead to false alarms or just plain inaccurate readings.

This happens because these materials are often *too* reactive on their surface, grabbing onto all sorts of different molecules without much fuss. We need something smarter, something that can pick out ethylene glycol from the crowd.

Enter Spinel Ferrites: A Smarter Approach

This is where a different class of materials comes in – spinel metal oxides. These guys are pretty special because their structure has multiple different metal ions hanging out together. This unique setup means they can interact with different gases in more distinct ways, making them much better at separating and identifying specific targets. They’re also getting a lot of love in the sensor world because they can be highly sensitive, aren’t crazy expensive to make, you can control how they’re synthesized, they’re generally non-toxic, and they conduct electricity well. All good things for a sensor!

Among these, Zinc Ferrite (ZnFe2O4, or ZF) has already shown some promise, partly because of its crystal structure which has some natural defects that help with sensing.

Boosting Performance: Doping and Porosity

But scientists are always looking to make things better, right? One common trick to boost a material’s sensing ability is ‘doping’ – adding a small amount of another element. The idea here was, what if we doped ZF with cobalt? Cobalt is known to help out in these kinds of materials. Plus, making the material super porous, like a tiny sponge, gives it a huge surface area. More surface area means more places for the gas molecules to interact with the sensor, which usually means a better and faster response.

So, the folks behind this research set out to make cobalt-doped ZF in a porous form – specifically, tiny porous spheres made of interwoven nanosheets. They used a relatively simple method called hydrothermal synthesis. They made samples with no cobalt (ZC0), 15% cobalt (ZC15), and 20% cobalt (ZC20) to see how the amount of doping affected things.

Checking Out the Goods: Characterization

Before testing them as sensors, they put these materials through the wringer with various analytical techniques. They used XRD to check the crystal structure and purity (yep, they confirmed the spinel structure and high purity!). FESEM gave them a look at the morphology – confirming those cool porous microspheres made of nanosheets. They saw that adding cobalt changed the size and sheet thickness of the spheres a bit. EDS analysis confirmed that the cobalt was actually in the doped samples.

FTIR spectroscopy helped confirm the formation of the spinel structure again. And BET analysis? That was key! It measured the surface area and pore characteristics. Guess what? The ZC15 sample (with 15% cobalt) had the largest effective surface area – almost double the pure ZF! This is a big deal because, as I mentioned, more surface area means more interaction spots for the gas. The porosity also helps the gas get *into* the material structure, not just sit on the outside.

They also looked at the optical properties using UV-Vis, finding that the band gap changed slightly with doping, which is interesting from a materials science perspective.

Putting Them to the Test: Sensing Performance

Alright, the moment of truth! How did these materials perform as ethylene glycol sensors? First, they had to figure out the best temperature to operate the sensor. They tested them at different temperatures and found that 210 °C was the sweet spot for the highest response. Too hot, and the gas doesn’t stick around long enough to be detected effectively.

Then, they exposed the sensors to different concentrations of ethylene glycol vapor, from 20 ppm all the way up to 500 ppm. As expected, the response increased with higher concentrations. But here’s the exciting part: the ZC15 sample consistently showed a *much* higher response than the pure ZF (ZC0) and the 20% doped sample (ZC20). For 500 ppm EG, ZC15 had a response of 119.6, compared to 107.5 for ZC0 and 78 for ZC20. That 15% cobalt doping really made a difference!

But it wasn’t just about *how much* they responded, but *how quickly*. These sensors showed incredibly fast response times – less than 3.6 seconds! The ZC15 sample, in particular, had a super speedy response time of about 1.8 seconds across different concentrations. The recovery time (how quickly it clears the gas and is ready for the next measurement) was a bit longer, but still quite good (ranging from 3.6 to 38.7 seconds depending on the sample and concentration). A fast response is crucial for quickly detecting dangerous leaks.

The Star Quality: Selectivity

Remember the selectivity problem I mentioned earlier? This is where the ZC15 sensor really shines. They tested its response to other common vapors like ethanol, acetone, isopropanol, methanol, and dimethylformamide, all at the same concentration (100 ppm) and temperature (210 °C). And guess what? The response to ethylene glycol was *significantly* higher than to any of the others. For ZC15, the response to EG was about 5.5 times higher than to acetone and 5 times higher than to ethanol! That’s fantastic selectivity, meaning you can be much more confident that when this sensor goes off, it’s actually detecting ethylene glycol.

Compared to some other ethylene glycol sensors reported in previous studies, this cobalt-doped ZF sensor showed a high response at a relatively low operating temperature and those super-fast response times. It’s definitely a strong contender!

So, Why Does It Work So Well? The Mechanism

Let’s get a little peek under the hood at *why* this material is such a good EG sensor. Like many metal oxide sensors, it works by changes in electrical conductivity. When the sensor is in clean air, oxygen molecules from the air stick to the surface of the material. These oxygen molecules grab electrons from the sensor material, turning into oxygen ions (like O₂⁻, O⁻, etc.). This creates a layer on the surface that’s missing electrons, which changes the material’s conductivity.

Now, when ethylene glycol vapor comes along, its molecules interact with these adsorbed oxygen ions. The electrons that the oxygen ions captured are then released back into the sensor material’s conduction band. This reduces that electron-deficient layer, changing the conductivity back. The sensor measures this change in conductivity, and *voilà* – it detects the gas!

How does the cobalt doping and porous structure help? Well, the porous structure gives that huge surface area, meaning way more spots for oxygen to adsorb and for EG to interact. It’s like opening up a huge parking lot for gas molecules instead of just having a few spots on the street.

The cobalt doping does something clever too. It seems to create new energy levels within the material’s electronic structure. Think of these as stepping stones that make it easier for electrons to move around and get captured by the adsorbed oxygen. This enhances the accumulation of chemically active oxygen on the surface. Plus, cobalt might help create more hydroxyl groups on the surface, which can form stronger bonds (hydrogen bonds) with ethylene glycol molecules, making the interaction more specific and robust. All these factors work together to give that enhanced sensitivity and selectivity, and contribute to the speedy response.

Wrapping It Up

So, what did I learn from this research? That these cobalt-doped porous ZnFe2O4 microspheres are pretty awesome for sensing ethylene glycol. They figured out a simple way to make them, and by adding just the right amount of cobalt (15% seems to be the magic number!), they created a sensor that’s not only highly sensitive to EG across a range of concentrations but also incredibly fast and, crucially, very selective. The combination of the high surface area from the porous structure and the electronic tweaks from the cobalt doping seems to be the winning formula.

This material looks like a really promising candidate for developing practical, high-performance ethylene glycol sensors. And anything that helps us detect hazardous substances more effectively is a big win in my book!

Source: Springer