Green Magic: Henna Helps Create Powerful Magnetic e Antibacterial Nanocomposites

Hey there! So, we’ve been diving into the fascinating world of tiny materials, specifically something called spinel ferrites. Now, these aren’t just any old materials; they’re pretty special because they can be magnetic *and* potentially fight off nasty germs. And guess what? We found a really cool, eco-friendly way to make them, using something you might even have in your kitchen cupboard – henna!

Why Spinel Ferrites Matter

Think of spinel ferrites as a family of oxides with some seriously useful talents. They’ve got high saturation magnetization (meaning they get strongly magnetic), they don’t conduct electricity very well (low electrical loss), and they’re super stable chemically. These traits make them stars in lots of different areas:

- Magnetic recording (like old hard drives, but way more advanced applications now!)

- Magnetic sensors

- Hyperthermia (using magnetic fields to heat and destroy things like cancer cells)

- Targeted drug delivery (guiding medicine right where it needs to go with a magnet)

- Catalysis (speeding up chemical reactions)

- Water purification (breaking down pollutants)

- Adsorbing dyes

- Antibacterial agents (fighting off microbes!)

Their magnetic properties and often good biocompatibility make them prime candidates for biomedical stuff, like MRI. And get this – doped spinel ferrite nanoparticles have already shown promise against various pathogens like E. coli and S. aureus.

We were particularly interested in cobalt ferrite (CoFe₂O₄), which is known for being a “hard” magnetic material with high coercivity, and manganese ferrite (MnFe₂O₄), which is more biocompatible and superparamagnetic, making it great for biomedicine and sensors. Swapping out some of the cobalt or iron with other elements like manganese, nickel, or chromium can totally change their personality, tuning their magnetic and other properties. For example, manganese substitution can make them more sensitive to stress, nickel doping makes them good for blocking electromagnetic interference, and chromium substitution affects their magnetic parameters like remanence and coercivity.

Meet the Henna-Green Method

Traditionally, these materials are made using various methods like hydrothermal synthesis, co-precipitation, or sol-gel. But we wanted to try something different, something greener and more efficient. That’s where our henna-green/microwave-assisted hydrothermal method comes in.

We basically combined the best bits of hydrothermal synthesis (it’s simple, cost-effective, and works at lower temperatures) with the perks of microwave heating (super fast, energy efficient, and can be scaled up). The “green” part comes from using henna extract. You know, the stuff used for temporary tattoos and hair dye? Turns out, it’s packed with natural compounds like polyphenols, flavonoids, and tannins. These act like little helpers, or “capping agents,” during the synthesis. They wrap around the growing nanoparticles, stopping them from clumping together and helping us control their size and shape. It’s an eco-friendly win!

We played around with different conditions – pH levels, temperatures, reaction times, and even how much henna extract we used – to see how it affected the final product. After finding the sweet spot for making cobalt-manganese spinel ferrite (Co₀.₅Mn₀.₅Fe₂O₄), we also tried swapping in nickel and chromium to see how that changed things.

Putting Them to the Test: Characterization

Once we had our samples, we put them through a battery of tests to figure out what we had made and what they could do.

Looking Inside with FTIR

First up was FTIR (Fourier Transform Infrared Spectroscopy). This basically tells us about the chemical bonds present. After heating our samples (calcination), the signals from the henna extract disappeared, and we saw clear peaks showing the formation of metal-oxygen bonds, confirming we had indeed made spinel ferrite. We even saw specific peaks corresponding to bonds in the tetrahedral and octahedral sites within the spinel structure. Pretty neat!

Crystal Structure Secrets from XRD

Next, we used XRD (X-ray Diffraction) to look at the crystal structure. All our samples showed the characteristic peaks of spinel ferrite, which has a cubic face-centered structure. However, for most samples (especially those calcined at 900°C), we also saw peaks for hematite (α-Fe₂O₃), another iron oxide. This hematite seems to pop up during the high-temperature heating step due to thermal decomposition and oxidation.

Interestingly, the amount of hematite depended a lot on our synthesis conditions. Things like pH, temperature, time, and even the concentration of henna extract influenced how much hematite formed alongside the spinel ferrite. For instance, lower pH seemed to lead to more hematite, likely because cobalt is more soluble than iron at lower pH, leaving iron free to form hematite. This shows just how crucial it is to control these parameters if you want to fine-tune the final material!

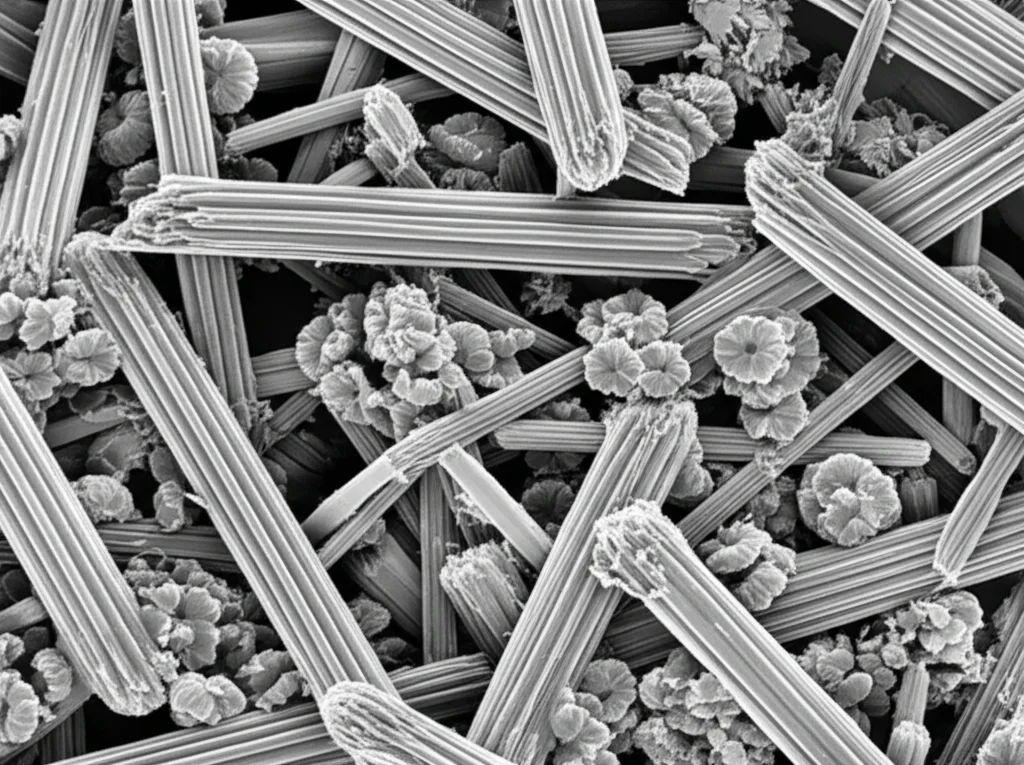

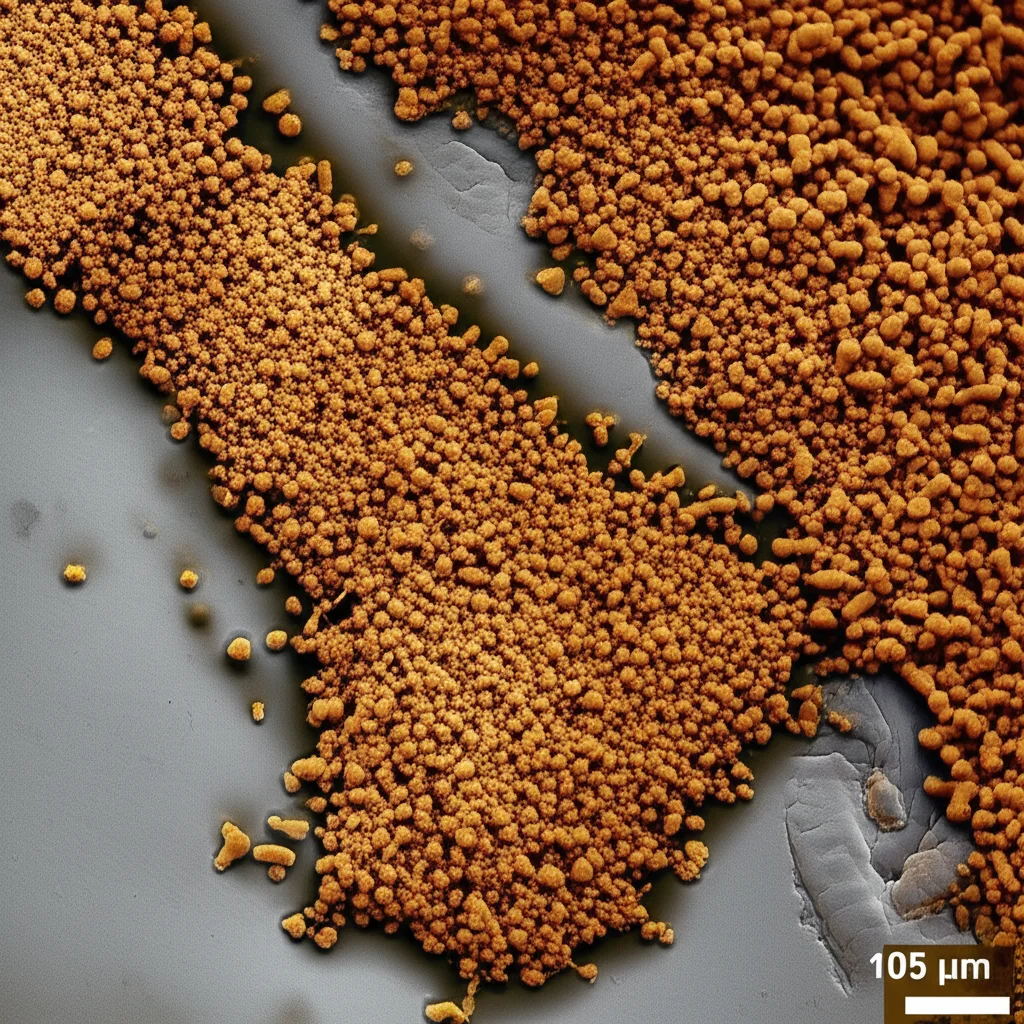

Seeing is Believing: SEM and TEM

To see what our nanoparticles actually looked like, we used SEM (Scanning Electron Microscopy) and TEM (Transmission Electron Microscopy). And wow, the shapes were diverse! We saw everything from short rod-like structures and flower-like shapes to polygonal and even elongated worm-gear shapes.

The henna extract played a huge role here. Samples made without henna were lumpy and agglomerated. But adding henna, especially at the right concentration, helped create smaller, more uniform, and well-dispersed particles with these cool shapes. This confirms that the natural compounds in henna are doing their job as capping agents, controlling how the particles nucleate and grow. pH, temperature, and time also influenced the morphology, sometimes leading to larger particles or different shapes due to processes like Ostwald ripening (where smaller particles dissolve and redeposit onto larger ones).

Checking the Elements: XPS

XPS (X-ray Photoelectron Spectroscopy) gave us a peek at the elements present and their oxidation states (basically, how many electrons they’ve gained or lost). Our analysis confirmed the presence of cobalt, iron, and the substituted elements (chromium, manganese, or nickel). We found that cobalt and nickel were primarily in the +2 oxidation state, while iron and chromium were in the +3 state. Manganese, being a bit more flexible, showed peaks consistent with the +2 oxidation state.

This analysis also helped explain why the nickel-substituted sample (NCF) was the only one that showed a pure spinel structure without any hematite in the XRD. Turns out, nickel (Ni²⁺) is super stable in the +2 state, prefers to sit in the right spots in the spinel structure, and has an ionic radius similar to cobalt. This makes it fit in nicely and makes the structure more stable, even at high temperatures. Manganese and chromium, with their multiple oxidation states and different ionic radii, cause more disruption, making it easier for hematite to form.

Feeling the Pull: Magnetic Properties

Alright, let’s talk magnetism! We measured the magnetic properties using a Vibrating Sample Magnetometer (VSM). All our substituted samples showed ferromagnetic behavior, meaning they can be permanently magnetized.

We looked at three key values:

- Saturation Magnetization (Ms): How strongly they get magnetized in a strong field.

- Remanent Magnetization (Mr): How much magnetism is left after the field is removed.

- Coercivity (Hc): How strong a field you need to apply to demagnetize them.

Our samples had Ms values ranging from 23.53 to 55.15 emu/g. The manganese-substituted sample (MCF) had the highest Ms (55.15 emu/g), followed by nickel (NCF, ~45.85 emu/g), and then chromium (CCF, ~23.53 emu/g). This is different from pure cobalt ferrite (~18 emu/g) or manganese ferrite (~15 emu/g), showing that the substitutions really do change the magnetic game!

Why the difference? It comes down to how the substituting ions (Cr³⁺, Mn²⁺, Ni²⁺) arrange themselves within the spinel structure and how their electron spins interact. Chromium substitution generally lowers Ms because Cr³⁺ has fewer unpaired electrons than the Fe³⁺ it replaces. Manganese’s effect is more complex, depending on where the Mn ions end up (tetrahedral or octahedral sites). Nickel substitution, while creating a stable pure spinel, also slightly reduces Ms compared to the manganese sample due to changes in magnetic interactions.

Fighting the Germs: Antibacterial Power

Now for the really exciting part for potential biomedical uses: fighting off germs! We tested our substituted samples (CCF, MCF, NCF) against common culprits: Escherichia coli (a Gram-negative bacterium), Staphylococcus aureus (a Gram-positive bacterium), and Candida albicans (a type of yeast). We measured how well they reduced the number of viable microbes (Colony-Forming Units or CFU).

Turns out, the chromium-substituted sample (CCF) was the champion! It showed the best reduction in CFU against all three types of microbes (87% for E. coli, 83% for S. aureus, and 86% for C. albicans). The manganese sample (MCF) was moderately effective, and the nickel sample (NCF) showed lower activity against E. coli and C. albicans but was pretty good against S. aureus.

Why is the chromium one so good? We think it’s mainly because Cr³⁺ ions are better at generating reactive oxygen species (ROS). These ROS are like tiny chemical weapons that damage the microbial cells. Also, Cr³⁺ has a higher charge density and smaller size compared to Mn²⁺ and Ni²⁺, which might help it interact more strongly with the negatively charged cell walls and cause more disruption.

This antibacterial power means these nanoparticles could be used in lots of cool ways, like:

- Cleaning up contaminated water

- Coating medical implants or tools to prevent infections

- Making antibacterial fabrics

Why This Method Rocks

Using the henna-green/microwave-assisted hydrothermal technique offers some sweet advantages:

- It’s eco-friendly – we’re using water as the main solvent and avoiding harsh chemicals.

- It’s fast and energy-efficient thanks to the microwave heating.

- It gives us good control over the synthesis, helping us get specific structures and properties.

- Using henna extract is a neat way to control particle size and prevent clumping.

Wrapping It Up

So, there you have it! We’ve successfully synthesized substituted cobalt spinel ferrite nanocomposites using a novel, green, and efficient method involving henna extract and microwave heating. We confirmed their spinel ferrite and hematite structures, saw how synthesis conditions and substitutions dramatically changed their shape, and verified the presence of our target elements in their expected oxidation states.

Most importantly, these tiny materials showed off their ferromagnetic properties and, particularly in the case of the chromium-substituted version, impressive antibacterial activity against common pathogens. This study really highlights the potential of this henna-green method for creating functional nanomaterials with tunable properties for various applications, from medicine to environmental cleanup. We’re excited to explore different compositions and dopants in the future to see what other cool things these materials can do!

Source: Springer

![Macro lens, 60mm, high detail, precise focusing image of a collection of colorful, glowing 3D molecular models representing the 2-(Aryl)benzo[d]imidazo[2,1-b]thiazole-7-sulfonamide derivatives, arranged on a dark, reflective surface with artistic, controlled lighting to emphasize their complex structures and potential as antitubercular and antibacterial agents.](https://scienzachiara.it/wp-content/uploads/2025/05/149_macro-lens-60mm-high-detail-precise-focusing-image-of-a-collection-of-colorful-glowing-3d-molecular-models-300x150.webp)