Unlocking Green Sand Mold Secrets: The Test That Gets It Right

Hey there! Ever wonder why making big, complicated metal parts, like for huge construction machines, can be such a headache? One major reason is something called “casting deformation.” That’s when the hot metal cools down inside its mold and shrinks, and if the mold doesn’t behave exactly as expected, the final shape gets warped. This costs a ton in rejected parts!

To try and avoid this, smart folks use computer simulations (like FEM) to predict how the metal will deform. But these simulations are only as good as the information you feed them about the mold itself. For green sand molds, which are super common for these big castings, we need a reliable “constitutive model” – basically, a mathematical description of how the mold material responds to stress. The Mohr-Coulomb (MC) model is a popular choice for sandy stuff like this.

The Old Way Had Some Snags

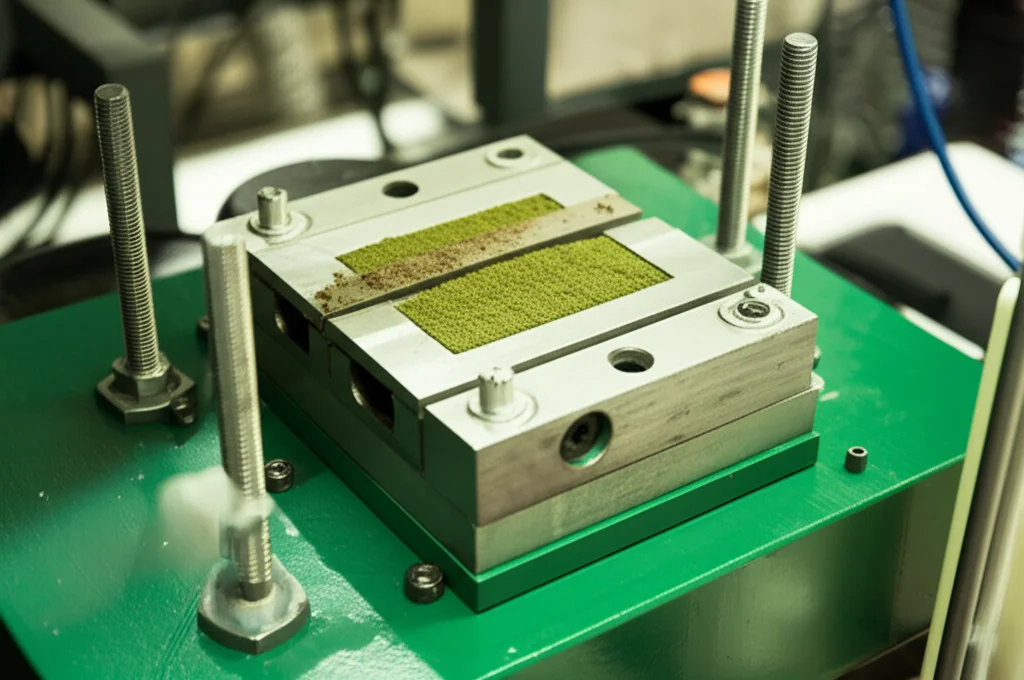

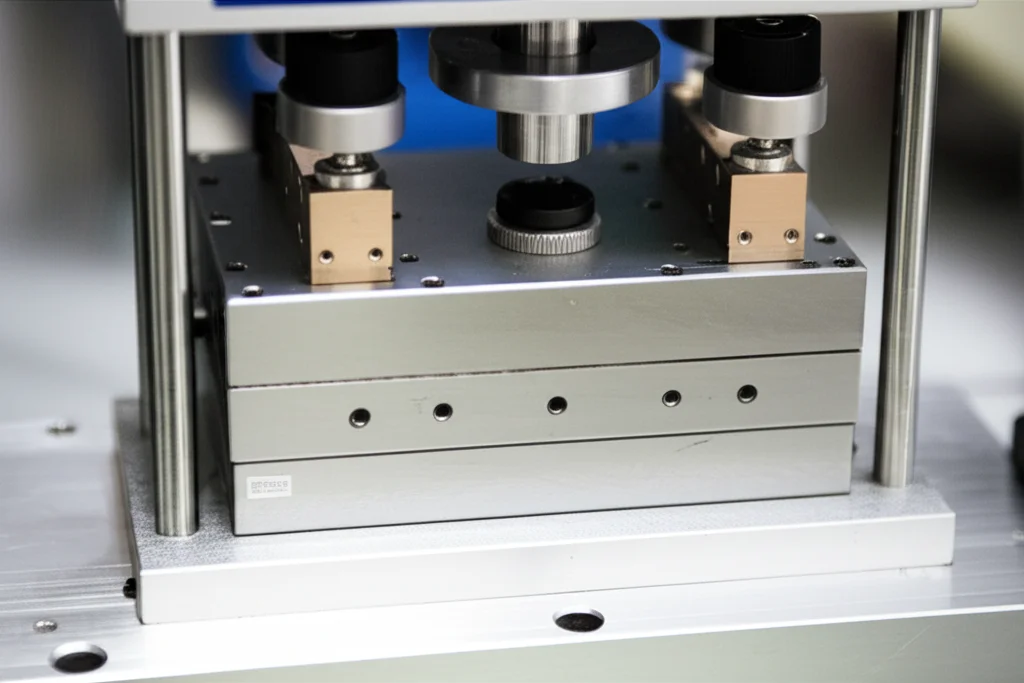

Getting the numbers (material constants like internal friction angle and cohesion) for the MC model usually involves a test called a “direct shear test.” It sounds straightforward: you put a sample of the sand mold in a box, apply pressure from the top, and then slide the bottom half of the box sideways to shear the sample. You measure the forces involved. Simple, right?

Well, not quite. Turns out, previous direct shear tests on green sand molds had a couple of pretty big issues that made the results questionable:

- Too Much Pressure: They often used vertical pressures way higher – sometimes ten times higher! – than what the sand mold actually experiences deep inside a real casting setup, just from the weight of the sand itself.

- Ignoring Sneaky Wall Friction: This is a big one. As you push down and shear the sand sample, it rubs against the inner walls of the shear box. This “wall friction” means the pressure you apply at the top isn’t fully transmitted down to the actual shear plane where the action is happening. What’s worse, as the sand shears, it can either shrink or *expand* (this expansion is called dilatancy), and this changes the direction and amount of that wall friction *during the test*. Previous methods often ignored this change or tried to estimate the pressure beforehand, which just wasn’t accurate.

If you ignore these things, especially the changing wall friction, you end up with numbers for your MC model that don’t truly represent the mold’s behavior.

A Smarter Way to Test

This is where the study we’re talking about comes in. They set out to fix these problems and get a truly reliable MC model for green sand.

First, they made sure to test the sand under more realistic pressures, closer to what you’d find in an actual mold (somewhere in the 0.01 to 0.1 MPa range).

Second, and this is the really clever part, they used a direct shear test device that could *directly measure* the vertical stress right on the shear plane *while the test was happening*. How? By putting a load cell (a force sensor) underneath the sample at the “reaction side.” The force measured by this load cell is the actual vertical force on the shear plane. This neat trick essentially eliminates the effect of the wall friction *during* the shearing process. Pretty slick, huh?

What They Found: The Truth About Mold Strength

So, what did this more accurate testing method reveal?

* Expansion is Key: At the lower, more realistic pressures (below 0.10 MPa), they observed that the green sand sample actually *expanded* as it was sheared. This is a different behavior than what happens at the higher pressures used in older tests, where the sample would contract.

* Friction Gets Tricky: Because the sample expanded, the direction of the wall friction actually reversed! Instead of pulling upwards (reducing the pressure on the shear plane), it pushed downwards, *increasing* the vertical stress on the shear plane compared to the pressure applied at the top.

* Overestimation Galore: This is the critical finding. When they compared the MC model parameters obtained using their accurate method (measuring vertical stress directly during shearing) with methods that ignored wall friction:

* Completely ignoring wall friction during shearing resulted in the mold’s shear strength being estimated as *twice as large* as the true strength found by the accurate method, especially at low vertical stresses.

* Using the previous estimation method (which measured friction *before* shearing) was even worse at low pressures because it didn’t account for the change in friction direction due to expansion. It significantly *misjudged* the wall friction’s effect.

Why This Matters for Your Castings

Think about it: if your computer simulation uses a mold model that thinks the sand is twice as strong as it really is, it’s going to predict that the mold provides a much stronger constraint on the cooling metal than it actually does. This leads to totally inaccurate predictions of how the casting will deform. You’ll design based on wrong information, and likely end up with those costly dimensional defects anyway.

By using the values obtained from the test method that *correctly* accounts for the vertical stress on the shear plane by eliminating the wall friction effect during shearing, engineers can finally build a truly reliable MC model for green sand molds.

Wrapping It Up

This study is a real game-changer for understanding green sand molds. By addressing the shortcomings of previous direct shear tests – using realistic pressures and, most importantly, developing a way to measure the *true* vertical stress during shearing – they’ve provided a reliable method to get the right numbers for the Mohr-Coulomb model.

They’ve also quantitatively shown just how much overestimation happens when you ignore that tricky wall friction and the sand’s expansion behavior at realistic pressures. Knowing this means engineers can use more accurate data in their simulations, leading to better designs, fewer rejected castings, and ultimately, saving a lot of time and money. Getting the science right at the material level makes a huge difference in the final product!

Source: Springer