Supercharging Aluminum: How We Made Alloys Tougher with Welding and Tiny Particles

Alright, let’s talk about aluminum alloys. You know, the stuff that makes airplanes fly and boats float? It’s pretty fantastic already – lightweight, strong, durable. That’s why industries like aerospace and marine love it. But what if we could make it even *better*? Especially for those really demanding spots, places with extreme temperatures, high humidity, or corrosive conditions? That’s exactly what we set out to explore.

We were particularly interested in two specific types: Al6061 and Al6082. Al6061 is a go-to for things like aircraft structures and car parts because it’s strong and welds nicely. Al6082 is a champ when it comes to resisting seawater and chemicals, making it perfect for marine applications. Now, sometimes you need the best of both worlds, right? You need to join these different materials together. That’s where dissimilar welding comes in – combining the unique strengths of different materials to get a superior result.

Enter Friction Stir Welding (FSW)

Forget traditional welding where you melt everything. FSW is this really cool, solid-state joining technique. Think of it like stirring materials together while they’re hot but not melted. It uses precise control of temperature, force, and movement. It’s known for being energy-efficient, environmentally friendly, and producing super high-quality joints without defects. We’ve seen FSW do amazing things with aluminum and other materials.

But we wanted to push the boundaries even further. What if we could add some “super-stuff” into the mix *during* the FSW process? We’re talking about reinforcement particles. A few folks have tried adding particles like SiC or Al₂O₃ to different aluminum alloys with FSW, and the results showed improved strength. So, we thought, why not try something a bit different, maybe even a mix?

Our Secret Ingredients: TiB₂ and Al₂O₃

We decided to focus on titanium diboride (TiB₂) and aluminum oxide (Al₂O₃) nanoparticles. TiB₂ is this super hard, white powder. Al₂O₃ is also a tough ceramic. Both have shown promise in boosting the properties of aluminum composites. We figured adding these during the FSW of Al6061 and Al6082 could create a novel material with seriously enhanced qualities.

So, how did we do it? We took plates of Al6061 and Al6082 and set them up for butt joining using FSW. Before welding, we created a little groove along the joint line. This groove was where our secret ingredients – the TiB₂ and Al₂O₃ nanoparticles – were placed. Then, the FSW tool came in. This tool isn’t just a stirrer; its shape (we used a conical pin and concave shoulder) is crucial. It generates heat through friction and mechanically mixes the materials, pushing the plasticized aluminum and our reinforcement particles around in the weld nugget zone (WNZ).

We optimized our FSW parameters – things like the tool’s rotation speed (2000 rpm) and how fast it moved along the joint (3 mm/min). These settings are key to getting enough heat and ensuring our particles are mixed evenly, not just clumped together. The tool material itself needs to be tough; we used stainless steel 316L. After the tool did its work in a single pass, we let the joint cool down naturally.

Putting Them to the Test: Wear, Strength, and Hardness

Once we had our welded joints, including those with the added particles and those without (for comparison), it was time for testing. We wanted to see how tough they were, how strong they were, and how well they resisted wear and tear.

First up, wear resistance. We used a pin-on-disc machine, which basically rubs a pin of our material against a spinning disc under a specific load. The results were pretty eye-opening! The base materials (Al6061 and Al6082 on their own) wore down the most. The FSW process itself improved wear resistance compared to the base materials, even without particles. This is because FSW refines the grain structure in the weld zone, making it harder and more resistant to wear.

But the real star? The material we reinforced with particles, especially the Al6061–Al6082/TiB₂ composite. It showed a significantly *reduced* wear rate – a whopping 30% less wear compared to the unreinforced FSW joints! This is because the hard TiB₂ particles act like tiny shields, taking the load and preventing the aluminum matrix from wearing away easily. They also help keep the grain size super small, which boosts hardness and wear resistance.

We also looked at the coefficient of friction – basically, how “slippery” the surface is when rubbed. Again, the reinforced materials, particularly the Al6061–Al6082/TiB₂, showed a lower friction coefficient (just 0.24). This means less friction, less heat generated during sliding, and better performance in applications where parts rub against each other.

Next, we checked their strength with tensile tests. We pulled the samples until they broke to see their ultimate tensile strength (UTS). Just like with wear, the FSW process improved the tensile strength compared to the base materials, thanks to that lovely grain refinement in the weld zone.

And guess what? The particle-reinforced joints were even stronger! The Al6061–Al6082/TiB₂ material hit the highest UTS, reaching an impressive 364 MPa. Why? Those hard particles act as barriers, making it harder for dislocations (tiny defects that move when you stretch a material) to slide around. This “pinning” effect, combined with the fine grains from FSW, makes the material much stronger.

Hardness tests (using a Vickers hardness tester) told a similar story. The weld nugget zone (WNZ) was generally harder than the surrounding areas (like the heat-affected zone), again because of the fine grains. And the particle-reinforced joints were harder still. The Al6061–Al6082/TiB₂ composite recorded a hardness of 100 HV. While interestingly, the *unreinforced* dissimilar joint showed a slightly higher peak hardness (105 HV) in some areas due to specific solid solution and precipitation effects, the *overall* enhanced properties from the uniform particle distribution and grain refinement in the reinforced samples, especially TiB₂, led to superior wear and tensile strength. The high hardness of the particles themselves contributes significantly, acting as tiny, hard islands within the aluminum sea.

Peeking Inside: Microstructure and Particles

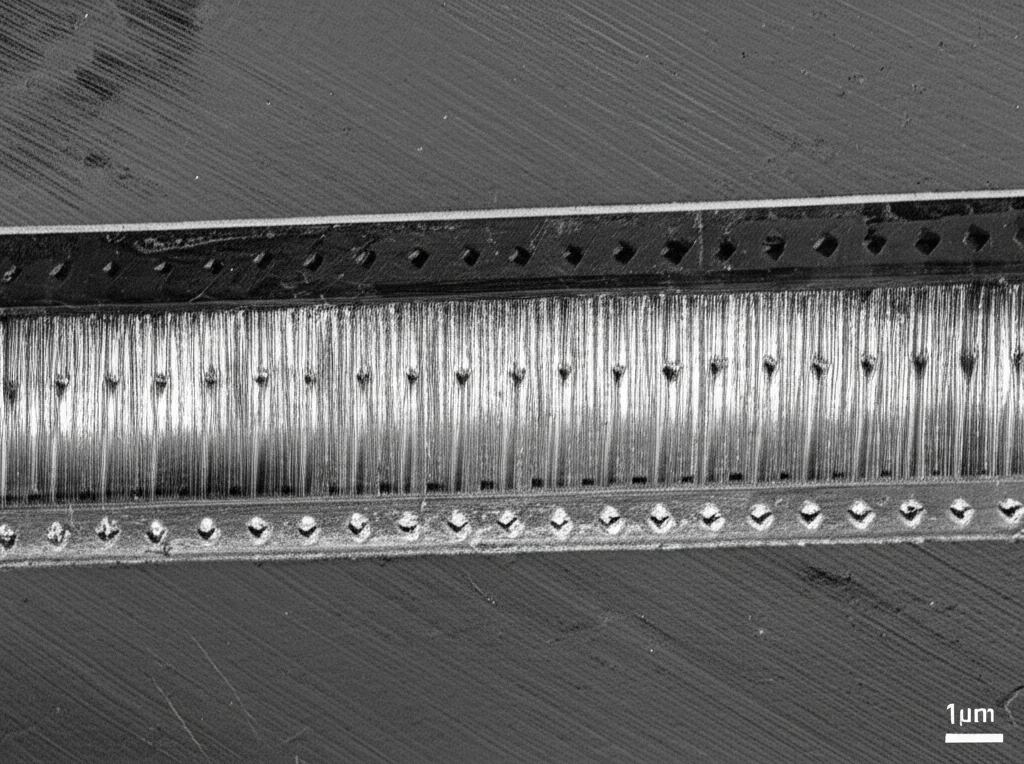

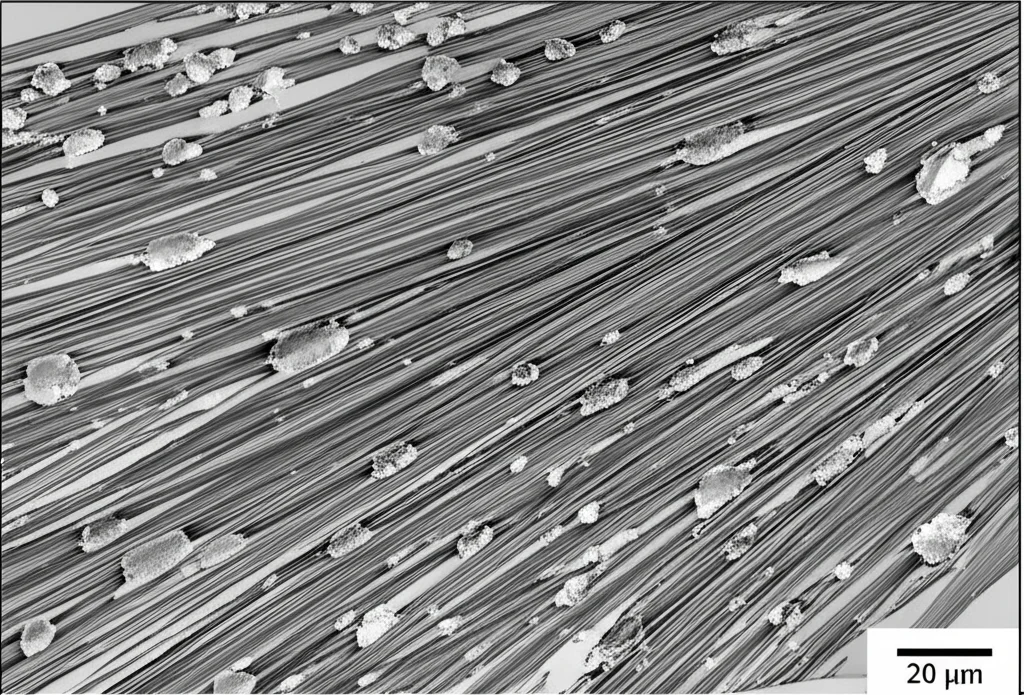

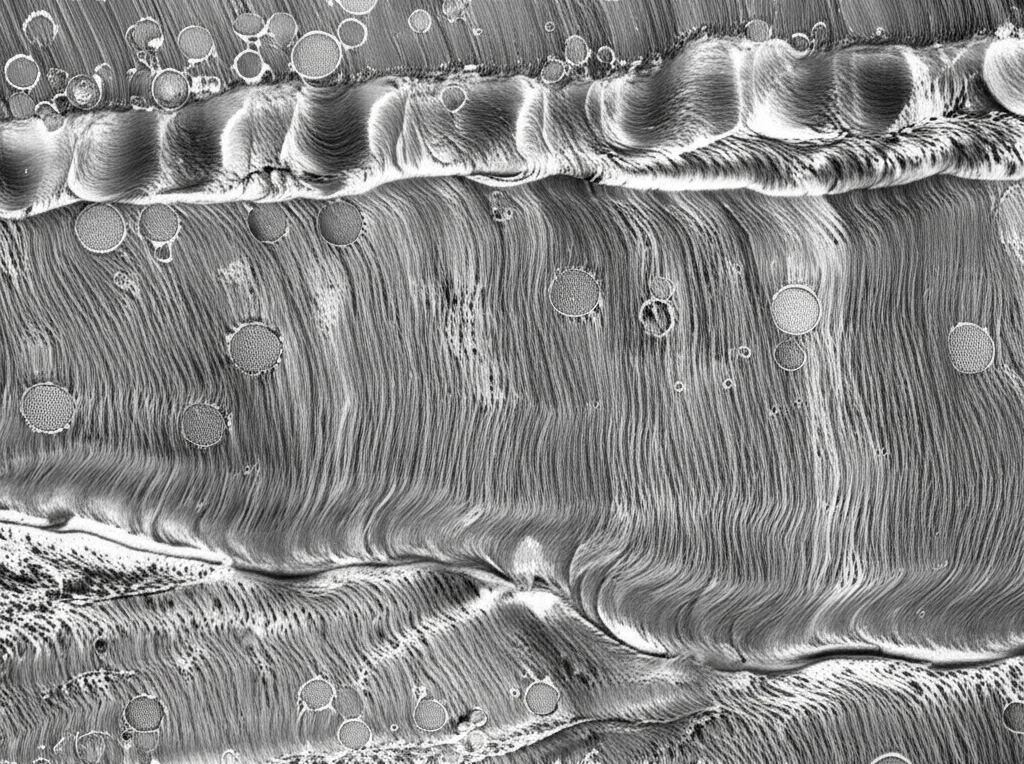

To really understand *why* these materials performed so well, we looked at their microstructure using techniques like Scanning Electron Microscopy (SEM) and Energy-Dispersive X-ray Spectroscopy (EDX). SEM images of the worn surfaces showed that the reinforced joints, particularly with TiB₂, had much smoother surfaces with less damage (fewer grooves, less material pulled out) compared to the unreinforced ones. This visually confirms the improved wear resistance.

Looking at the fracture surfaces after tensile testing gave us clues too. The reinforced samples showed signs of ductile fracture (little dimples), suggesting they absorbed more energy before breaking, though the Al₂O₃ samples showed some particle pullout, indicating weaker bonding there. The TiB₂ samples seemed to have better particle-matrix adhesion.

EDX mapping was super helpful. It showed us how well the TiB₂ and Al₂O₃ particles were distributed in the weld zone. For the best results, you want them spread out evenly, not clumped up. Our EDX analysis confirmed a nice, uniform dispersion of Ti and B (from TiB₂) and Al and O (from Al₂O₃) throughout the weld nuggets. This uniform distribution is key to the particles doing their job effectively – blocking dislocations and strengthening the material.

We also saw clear evidence of grain refinement in the weld nugget zone under the microscope. The FSW process, especially with the help of the particles acting as nucleation sites, created much finer grains compared to the original materials. Remember the Hall-Petch relationship? Smaller grains mean higher hardness and strength. This grain refinement is a huge factor in the improved mechanical properties.

So, What’s the Big Takeaway?

Adding hard reinforcement particles like TiB₂ and Al₂O₃ during the FSW of dissimilar aluminum alloys like Al6061 and Al6082 is a fantastic way to boost their performance. We saw significant improvements in:

- Wear Resistance: Much less material loss, especially with TiB₂ (30% reduction!).

- Friction: Lower coefficient of friction, meaning smoother operation.

- Tensile Strength: Stronger joints, able to withstand higher loads (364 MPa with TiB₂).

- Hardness: Harder material in the weld zone, resisting deformation.

These enhancements come from a combination of factors:

- Grain Refinement: FSW creates tiny grains, making the material tougher.

- Particle Strengthening: TiB₂ and Al₂O₃ particles block dislocation movement and bear some of the load.

- Uniform Dispersion: Getting the particles spread out evenly is crucial for consistent performance.

While both TiB₂ and Al₂O₃ helped, TiB₂ really stood out in this study for achieving the best combination of wear resistance, tensile strength, and hardness. This work gives us some really valuable insights for creating super-tough aluminum structures for those harsh environments – think stronger, more durable parts for planes, ships, and cars.

Of course, there’s always more to explore! We can keep playing with the FSW parameters and the amount/type of particles to see if we can make them even better. But for now, we’re pretty excited about the potential of this approach to create high-performance aluminum matrix composites.

Source: Springer