Diamond Films: How a Little Gas Juggling Makes Them Super Smooth and Tough!

Hey everyone! Ever thought about diamonds? Not just the sparkly ones in jewelry, but the super-strong, super-slick coatings we can make in the lab? I’m talking about diamond films, and they’re pretty amazing. They boast incredible hardness and super low friction, which sounds perfect for all sorts of high-tech applications, right? But there’s a catch – often, these films end up with a surface rougher than a badger’s backside. Not ideal if you want things to slide smoothly!

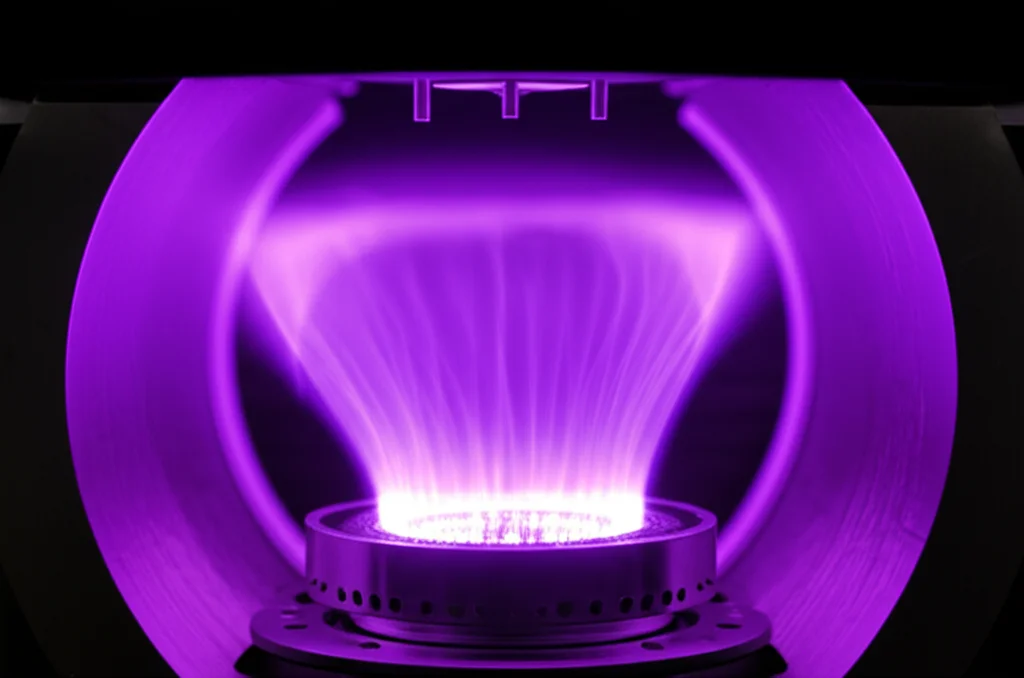

So, what if I told you we’ve been playing around with a neat trick to get these diamond films both super-strong and super-smooth? It’s all about “concentration modulation” during their synthesis using something called microwave plasma chemical vapor deposition (CVD). Sounds fancy, I know, but stick with me, it’s pretty cool.

So, What’s the Big Deal with Rough Diamond Films?

Diamond itself is a wonder material. It’s incredibly hard, doesn’t like to rub up against things (low friction), and resists wear like a champ. That’s why it’s a go-to for things like sliding parts in machinery. We typically grow these films using CVD, where we feed gases like methane (CH4) and hydrogen (H2) into a chamber and let the magic happen with microwaves. Depending on how much methane we use, we can get different types of diamond films.

For instance, microcrystalline diamond (MCD) films, usually made with about 1% methane, are super wear-resistant. Awesome! But, their surface is often quite rough, which can actually wear out the material they’re sliding against. To fix this, they need a lot of polishing after they’re made, and that costs time and money. Nobody likes extra costs!

On the other hand, if we crank up the methane to around 10%, we get nanocrystalline diamond (NCD) films. These guys have a much smoother surface, which is great. But, they tend to be a bit softer and don’t resist wear as well. So, it’s like choosing between a tough brute and a smooth operator – why can’t we have both?

People have tried making laminated films, layering MCD and NCD, which helps. Some have even tried quickly switching the methane concentration between 2% and 3% to get films smoother and harder than traditional MCD, without creating distinct layers. There’s also this stuff called nanopolycrystalline diamond (NPD), which is made under high-temperature and high-pressure and is insanely hard (up to 140 GPa!), but making NPD thin films with that kind of hardness and tiny particle size is a real challenge.

Our Little Trick: Concentration Modulation!

We had a hunch that if we could cleverly switch the methane concentration during the growth process, we might hit a sweet spot. We’d previously made a smooth and hard NCD film by flipping the methane between 1% and 10% every 5 minutes. But we wanted to dig deeper, see how changing the *frequency* of this switching – the modulation – affected the film’s properties. Could we make them even harder? Even smoother?

So, we set up our microwave plasma CVD system. We used standard silicon wafers as our base (they’re great for these kinds of fundamental studies). We’d scratch them up a bit with diamond powder (sounds counterintuitive, but it helps the new diamond to start growing!) and then give them a good clean.

Our main recipe for what we call concentration-modulated diamond (CMD) films involved switching the methane (CH4) concentration. We had two steps:

- Step 1: Higher methane concentration (10%)

- Step 2: Lower methane concentration (1%)

We’d alternate these steps every 2 to 5 minutes. We kept the hydrogen flow steady, the pressure at 6 kPa (which we had to manually tweak because changing gas flows can mess with it!), and the microwave power at 400 Watts. The whole cooking time was about an hour. For comparison, we also made standard MCD films (at a constant 1% CH4 for 2 hours) and NCD films (at a constant 10% CH4 for 2 hours), plus a couple of films at steady 5% and 6% CH4.

What Did These Modulated Films Look Like?

First, we took a peek at their surfaces and cross-sections using a scanning electron microscope (SEM).

The MCD film, as expected, had clearly visible crystals and a rough surface – its roughness (we call it Sz) was about 1.02 µm. The NCD film, made of tiny diamond particles, was much smoother, with an Sz of just 0.19 µm. Interestingly, we found that the switch from MCD-like rough surfaces to NCD-like smooth ones happened somewhere between 5% and 6% methane concentration if we kept it constant.

Now, for our CMD films! They looked a lot like the NCD films – composed of small diamond particles with lovely smooth surfaces. Their Sz values were all pretty low, ranging from 0.15 µm to 0.21 µm. When we looked at their cross-sections, we didn’t see the large grain growth typical of MCD films; instead, their structure was very NCD-like. It seemed that the deposition rate (how fast the film grew) actually decreased a bit if we switched the concentrations more frequently.

This makes sense when you think about what’s happening. At low methane (around 1%), hydrogen in the plasma is busy etching away any non-diamond stuff and helping the diamond crystals grow big. At high methane (around 10%), this etching effect is weaker, and new diamond crystals (nucleation) tend to pop up more readily. So, by switching, we’re trying to get the best of both worlds – enough nucleation for small grains and smoothness, with some growth to keep things strong.

Digging into the Structure: XRD and Raman Insights

To get a better idea of the crystal structure, we used X-ray diffraction (XRD). All our films showed the characteristic diamond peaks, which is always a good sign! We used the XRD data to estimate the size of the tiny crystals (crystallites). The NCD film had crystallites around 5.6 nanometers. Our CMD films? Their crystallites were consistently a tad larger, ranging from 5.7 to 6.2 nm. This suggests that the low-methane part of our modulation cycle (Step 2) was indeed allowing for a bit of crystal growth.

Next up was Raman spectroscopy, a fantastic tool for telling us what kind of carbon bonds we have.

The MCD film showed a nice, sharp peak for diamond. The NCD film was more complex: it had peaks for amorphous carbon (the D band) and graphite (the G band), along with a weaker diamond peak. It also showed peaks related to something called trans-polyacetylene (t-PA), which is linked to nanoscale diamond growth, and another peak (dnc) related to tiny diamond clusters. These five peaks are classic NCD signatures. And guess what? Our CMD films showed these same NCD-like Raman spectra!

We then did some fancy deconvolution of these Raman spectra. Two ratios are particularly interesting:

- Idnc/Id: This tells us about the “nanocrystallinity.” A smaller grain size usually means a larger Idnc/Id.

- It-PA/IG: This helps us gauge the relative amounts of nanoscale diamond versus graphite.

The NCD film had the highest Idnc/Id (smallest grain size, as we saw with SEM), but its It-PA/IG value was lower, meaning it had a fair bit of graphite. For our CMD films, the It-PA/IG values actually increased when we switched the concentrations more frequently. This is great news because it suggests we were getting less graphite in the films! The Idnc/Id values didn’t show such a clear trend with frequency, but the key takeaway was that by playing with the modulation frequency, we could reduce unwanted graphite and tweak the diamond grain size.

The All-Important Question: How Hard Were They?

Okay, so they’re smooth and have a nice structure, but are they tough? We measured their hardness using an ultra-micro indentation method.

The MCD film was pretty hard, around 71.0 GPa, but because of its rough surface, the hardness values varied quite a bit. The NCD film, as expected, was softer.

And our CMD films? They were consistently harder than the NCD films! Even better, the film hardness generally increased as we increased the modulation frequency (up to a point). The champion was our CMD3 film (modulated every 3 minutes), which clocked in at an average of 61.1 GPa. This clearly shows that modulating the CH4 concentration is a great way to boost hardness while keeping things smooth.

It seems there’s a sweet spot. The It-PA/IG ratio (less graphite) correlated well with the hardness for most CMD films. A longer low-methane step (Step 2) allows more time to etch away non-diamond bits formed during the high-methane step (Step 1) and promotes diamond growth, leading to higher hardness. However, if we switched too fast (like in our CMD2 film, modulated every 2 minutes), the hardness dipped a bit. It could be that the short low-methane step wasn’t quite enough to clean things up perfectly, even though the It-PA/IG value was still high. More digging needed there!

The Rub: Friction and Wear Performance

Finally, the big test: how do these films perform when things get rough, literally? We used a ball-on-disk tester, rubbing an alumina (Al2O3) ball against our diamond films.

The MCD film started with a higher friction coefficient, which gradually settled to about 0.16. The NCD film had a lower friction coefficient, around 0.08, but it fluctuated quite a bit.

Our CMD films were the real stars here! Their friction coefficients dropped quickly and stabilized at values below 0.1 – some even as low as 0.03 on average! That’s significantly better than both MCD and NCD films.

We then looked at the wear on the alumina ball and the films themselves. The alumina ball is pretty hard (20-25 GPa), but all our diamond films are harder, so we didn’t expect much wear on the films. However, the NCD film surface did show some abrasion marks. When we looked at the specific wear rate of the alumina ball, it was much lower when rubbing against any of our CMD films compared to when it rubbed against MCD or NCD films. In fact, the wear rate on the counterpart material was reduced by over 90% compared to conventional diamond films! That’s a huge improvement.

So, what’s going on?

- The MCD film, being hard but rough, likely caused abrasive wear on the alumina ball. As the ball wore down, the contact pressure decreased, and so did the friction.

- The NCD film, while smooth, had more non-diamond components and lower wear resistance. We even saw some black particles in its wear tracks, which could be debris from the ball, the film, or bits of the film that broke off. These particles would act like grit, increasing wear on the ball.

- Our CMD films, however, hit the jackpot: smooth surface, plenty of nanoscale diamond, and good hardness (around 60 GPa). They didn’t seem to wear or have particles break off like the NCD film. This led to a low, stable friction coefficient and much less wear on the alumina ball.

It seems the friction coefficient and wear aren’t just about surface roughness or hardness alone; it’s a combination. The CMD films seem to get that combination just right.

Wrapping It All Up: The Magic of Modulation

So, what have we learned from all this mucking about with methane concentrations? It turns out that by cleverly modulating the CH4 concentration during microwave plasma CVD, we can really fine-tune the properties of our diamond films.

- We can synthesize films with a surface roughness similar to NCD films, and we can even reduce this roughness by tweaking the modulation frequency.

- We can improve the nanoscale diamond structure and boost the hardness compared to standard NCD films. Again, the modulation frequency is our control knob here.

- Most excitingly, we can significantly reduce the wear on the material rubbing against our diamond films, much more so than with traditional MCD or NCD films. The friction coefficient also behaves beautifully.

Essentially, by carefully adjusting the high-methane (Step 1) and low-methane (Step 2) periods, we can control the surface morphology, the internal structure (like how much diamond versus non-diamond stuff we get), and the hardness of the films. And all this control leads to some seriously impressive friction and wear performance. It’s a pretty neat way to get the best of all worlds: smooth, hard, and low-friction diamond films! Who knew a little gas juggling could be so effective?

Source: Springer