Unlocking Aircraft Engine Secrets with AI: 1D CNNs Take Flight

Hey there! Ever wonder how those massive jet engines stay in tip-top shape? It’s not just about wrenching and checking oil. Nope, in the modern world of aviation, it’s increasingly about smart tech, specifically artificial intelligence (AI) and machine learning (ML). We’re talking about predicting potential hiccups *before* they become big problems. This is super important for keeping flights safe, managing airline fleets efficiently, and honestly, saving a ton of cash and reducing our environmental footprint.

Why Engine Health Monitoring is a Big Deal

Think about it: a gas turbine engine is a complex beast. It’s got parts spinning incredibly fast, handling extreme temperatures and pressures. Keeping tabs on its performance and health is absolutely crucial. Traditionally, this involved scheduled maintenance and reacting when something went wrong. But with digital flight data recorders (DFDRs) capturing tons of information during every single flight, we’ve got a treasure trove of data just waiting to be analyzed.

Now, wading through that data manually? That’s a nightmare. It’s costly and takes forever. This is where intelligent techniques like ML swoop in. They can process vast amounts of data quickly, accurately, and reliably. It’s like having a super-powered detective constantly monitoring the engine’s pulse.

One of the key indicators of engine health is the Exhaust Gas Temperature (EGT). If the EGT starts creeping up, it’s often a sign that things aren’t running as efficiently as they should be. This could mean wear and tear on components. Every engine has an EGT limit, and hitting that limit means a costly trip to the maintenance shop and, worse, the aircraft being stuck on the ground. So, being able to predict EGT – and other vital parameters – is a game-changer for operators and manufacturers alike.

Modern aircraft are packed with sensors, generating even *more* data. This makes fault identification and isolation more challenging, but also provides the fuel (pun intended!) for advanced ML techniques. Predictive analysis is key for engine health monitoring, helping to:

- Predict performance degradation.

- Reduce maintenance costs.

- Minimize in-flight shutdowns.

- Control fuel consumption.

- Avoid unexpected delays and cancellations.

Our Subject: The PW-4056-3 Engine on a Boeing 747-400F

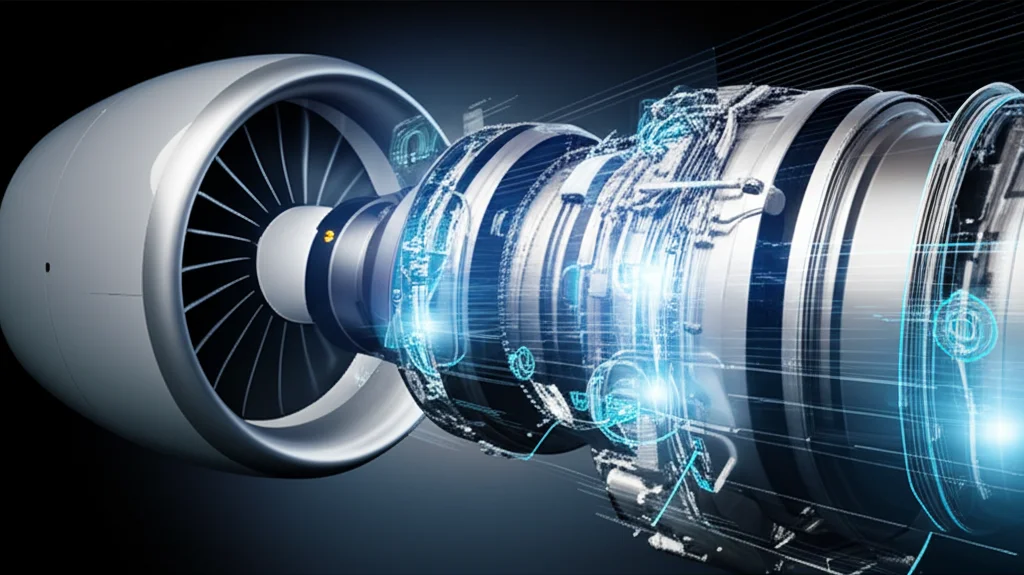

For this particular deep dive, we focused on the PW-4056-3 engine, a typical turbofan found on the Boeing 747-400F. These engines have various sections – the fan, low-pressure compressor (N1), high-pressure compressor (N2), combustor, and turbines – all contributing to performance and monitored by sensors for speed, fuel flow, temperature (like EGT), and vibration (VIB). This real-time data is logged in the DFDRs.

We got our hands on data from a couple of flights in August 2021. This wasn’t just some random grab; it was specific data recorded during the taxi, takeoff, and climb phases – critical moments where engines are really working hard. This data, pulled from the DFDR via the quick access recorder (QAR) and a flight data acquisition unit (FDAU), became the input for our ML magic.

Enter the 1D Convolutional Neural Network (CNN)

So, how did we tackle predicting these engine parameters? We decided to use 1D Convolutional Neural Networks (CNNs). Now, you might have heard of CNNs being used for image recognition – they’re fantastic at finding patterns in grids of data. But they’re also brilliant for sequential data, like the time series of engine parameters recorded during a flight. That’s where the “1D” comes in – they process data along a single dimension (time).

CNNs are a type of deep learning model. They’re great because they can automatically learn complex features and patterns directly from the raw data. They use convolutional layers to scan the data for specific patterns, followed by other layers to process these patterns and make a prediction. We used standard ML libraries like TensorFlow and PyTorch to build and train our models.

Our goal was to predict N1, N2, EGT, fuel flow (FF), and vibration (VIB) for four engines across different flights. We split our dataset – a hefty 3270 samples – into 80% for training the model and 20% for testing how well it performed on data it hadn’t seen before.

Putting the Model to the Test: Metrics Matter

To know if our predictions were any good, we needed ways to measure accuracy. We used a few standard metrics:

- Mean Squared Error (MSE): This tells us the average squared difference between our predicted values and the actual values. Lower is better.

- R-squared (R2): This indicates how well our model fits the data, essentially how much of the variation in the actual data is explained by our model. A value closer to 1 is better (1 means a perfect fit).

- Mean Absolute Error (MAE): This is the average absolute difference between predictions and actual values. It’s another way to see how far off our predictions are, on average. Lower is better.

No single metric tells the whole story, so using a combination gives us a robust picture of the model’s performance. We tweaked some settings, like the ‘learning rate’ and ‘batch size’, to get the best possible accuracy.

What Did We Find? The Results Are In!

Alright, let’s get to the exciting part – the results! Our 1D CNN model did a pretty solid job predicting the engine parameters. The accuracy varied depending on the parameter, ranging from about 80% to 99%. This is considered quite acceptable for predicting engine performance, and in some cases, even better than what’s been reported for similar models in other studies.

Here’s a quick rundown of what we observed for the specific parameters during the takeoff and climb phases:

- N2 (High-Pressure Compressor): This parameter was remarkably stable. Our model predicted an average value around 94.93%, which is right where it should be. Like a rock, N2 stayed steady.

- EGT (Exhaust Gas Temperature): The EGT predictions aligned well with the actual data. During takeoff and initial climb, the temperature reached around 600°C, dropping to about 540°C at higher altitudes. This matches the engine’s technical specifications and standard values. The model captured this behavior accurately.

- FF (Fuel Flow): Fuel flow is directly related to EGT and engine power. Our predictions showed that the fuel consumption rate stabilized after reaching the transition altitude, averaging around 6800 kg per hour. This is also in compliance with standard parameters and demonstrates the model’s ability to predict this highly predictable performance.

- N1 (Low-Pressure Compressor): Now, this one showed some interesting behavior, and our model picked up on it. Right after takeoff, within the first 81 seconds, the actual N1 values fluctuated noticeably, between 97% and 97.84%. Our model’s predictions tracked this variation. N1 is a primary indicator of thrust, so this fluctuation is significant.

- VIB (Vibration): This was the trickiest parameter to predict accurately, and our model showed it was the least efficient here. The fluctuation in N1 right after takeoff had a significant impact on vibration, causing some abnormal trends with chaotic frequency changes. While the model captured the general trend, the prediction wasn’t as precise as for the other parameters. This makes sense because vibration can be influenced by many factors beyond just the engine’s core performance, like imbalances or external forces.

The comparison graphs (which, sadly, I can’t *show* you here, but trust me, they look pretty convincing!) illustrate how closely the orange lines (our CNN predictions) followed the blue lines (the true values) for EGT, FF, N1, and N2. Vibration was a bit more scattered, as expected.

Why This Matters: Real-World Impact

So, what does this all mean in the real world? Having an accurate way to predict engine performance parameters using ML like 1D CNNs is incredibly valuable for several reasons:

- Predictive Maintenance: Instead of waiting for something to break or sticking to rigid schedules, airlines and maintenance crews can use these predictions to know *when* an engine might need attention *before* it causes a problem. This allows for timely maintenance, reducing unexpected breakdowns and costly emergency repairs.

- Cost Savings: By keeping engines running at their optimum efficiency (which the predictions help monitor), airlines can reduce fuel consumption. Catching issues early also means repairs are often less extensive and expensive.

- Safety: Predicting potential anomalies or performance degradation contributes directly to flight safety by addressing issues proactively.

- Engine Development: Manufacturers can use these insights to develop even more accurate engine models and improve designs.

The ability to integrate real-time data and provide timely recommendations for maintenance actions is a big step forward. It moves us beyond traditional monitoring towards a more intelligent, data-driven approach.

Looking Ahead

Our study shows that the 1D CNN model is a reliable tool for estimating key gas turbine engine parameters with acceptable effort and accuracy. While vibration prediction is still a bit challenging due to its complex nature, the results for N1, N2, EGT, and FF are highly promising.

For airlines and leasing companies managing large fleets, this kind of early detection of performance degradation is gold. It allows them to schedule engine removals and maintenance visits strategically, avoiding higher overhaul costs and financial losses associated with poor performance or unexpected failures.

Basically, catching a fault early, while it’s just starting to change the engine’s “standard signature,” is key. Trend monitoring and analysis using advanced tools like our CNN model can give those early warnings.

The world of AI and ML in aviation is evolving rapidly, and techniques like 1D CNNs are proving to be powerful allies in ensuring the safety, efficiency, and sustainability of air travel. It’s exciting to see how these digital innovations are transforming how we keep those incredible machines flying smoothly!

Source: Springer