Boosting Vitamin K2: Supercharging MK-7 Production with Bacteria

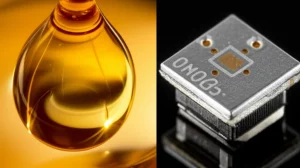

Hey there, science enthusiasts and health-conscious folks! We’re diving into something pretty cool today – how we can get more of a super important nutrient called Menaquinone-7, or MK-7 for short. You might know it as a key player in the Vitamin K2 family. This stuff is vital for keeping our bones strong, our hearts happy, and maybe even tackling some other health puzzles. But here’s the catch: getting enough MK-7 at a decent price has been a bit tricky. Why? Well, making it through fermentation hasn’t always given us huge amounts, and cleaning it up afterward is a bit of a headache.

With the demand for MK-7 skyrocketing in the health and pharma worlds, finding ways to make it efficiently is a big deal. That’s exactly what this study is all about! We wanted to find a way to seriously boost MK-7 production using a specific little helper: a strain of bacteria called Bacillus subtilis MM26, which was actually found chilling in some homemade fermented wine. Pretty neat origin story, right?

Finding the Sweet Spot: Initial Optimization

Our first mission was to figure out the absolute best conditions for our little bacterial friends, Bacillus subtilis MM26, to pump out MK-7. We started with a basic production medium and got an initial yield of about 67 mg/L. Not bad, but we knew we could do better!

We used a straightforward method called One Factor at a Time (OFAT). Think of it like tweaking one knob on a stereo while keeping all the others still to see what happens. We tested different:

- Carbon sources: What the bacteria eat for energy.

- Nitrogen sources: Essential building blocks for growth.

- pH levels: How acidic or alkaline the environment is.

- Temperatures: How warm things should be.

- Inoculum sizes: How much of the bacteria we start with.

What we found was pretty interesting. For carbon, lactose turned out to be the winner, giving us about 69 mg/L. Glycerol was okay, but lactose was better. Surprisingly, dextrose and maltose didn’t work at all for MK-7 production with this strain! For nitrogen, glycine was the star, also hitting around 69 mg/L, beating out soy peptone, tryptone, and beef extract. Peptone, like dextrose and maltose, was a no-go.

We also figured out the ideal environment:

- pH: A nice neutral 7 was perfect (69 mg/L).

- Temperature: A cozy 37°C did the trick (65 mg/L).

- Inoculum size: Starting with 2.5% of our bacterial culture gave the best results (68 mg/L).

These initial OFAT results gave us a solid foundation, showing us which ingredients and conditions were most promising. But OFAT only tells you about one factor at a time. To really optimize things, we needed to see how these factors worked *together*.

Getting Serious with Statistics: Response Surface Methodology

This is where things get a bit more sophisticated. To truly maximize the MK-7 yield, we employed a statistical technique called Response Surface Methodology (RSM). Instead of changing just one thing at a time, RSM lets us look at how multiple factors interact and influence the outcome. It helps us find the absolute peak of production efficiency within our experimental space.

Based on our OFAT findings and previous research, we focused on the factors that seemed to have the biggest impact: incubation time, our best carbon source (lactose), and our best nitrogen source (glycine). We used a specific RSM design called Box-Behnken, which involved 17 different experimental runs, each with varying levels of these three factors.

We set up these experiments, let our *Bacillus subtilis* MM26 cultures grow under the specified conditions, and then measured the amount of MK-7 produced using fancy equipment like HPLC (High-Performance Liquid Chromatography) and FTIR (Fourier-Transform Infrared Spectroscopy) to make sure it was definitely MK-7.

The Big Reveal: Optimized Yields!

And the results? Drumroll, please… In one of the runs (specifically the 12th one), we hit a massive yield of 442 ± 2.08 mg/L of MK-7! Remember our starting point was around 67 mg/L? That’s a whopping 6.4-fold increase just by optimizing the conditions!

The statistical analysis from RSM confirmed that incubation time, lactose, and glycine were indeed the key players significantly affecting MK-7 production. Glycine, in particular, seemed to have the biggest influence. The model we generated from the data was a great fit, meaning it accurately predicted the yields based on the factor levels. This gives us a lot of confidence in our findings.

We also looked at 3D graphs (response surface plots) generated by the model. These plots visually showed how changing the amounts of lactose and glycine, and the incubation time, affected the final MK-7 yield. It was clear that there’s a sweet spot for each factor, and getting the right combination is crucial for hitting that high production number.

Why This Is Exciting

So, why is this such a big deal? Well, previous studies using other strains or different methods often reported much lower MK-7 yields. Our *Bacillus subtilis* MM26 strain, combined with this optimized bioprocess, blew many of those earlier results out of the water, showing approximately a 4.65-fold increase compared to some reported values.

This study successfully demonstrated that by carefully selecting the right carbon and nitrogen sources (lactose and glycine) and optimizing their concentrations along with incubation time using RSM, we can dramatically enhance MK-7 production from this specific bacterial strain. It highlights how important it is to tailor the fermentation conditions to the particular microorganism you’re working with.

Achieving such a high yield is a major step towards making MK-7 production more efficient and potentially more cost-effective on an industrial scale. This could mean more affordable access to this valuable nutrient for people around the world.

Looking Ahead

This is a fantastic start, but the journey isn’t over. Future work will likely involve digging even deeper, perhaps using metabolic and genetic engineering techniques to make *Bacillus subtilis* MM26 an even better MK-7 factory. We also need to figure out the most cost-efficient ways to purify the MK-7 once it’s produced (the “downstream processing” part). But for now, we’re pretty thrilled with the potential shown by this little bacterium from homemade wine!

Source: Springer