Cracking the Code: How AI Helps Us Predict When Welded Steel Will Give Up the Ghost!

Hey there, fellow material enthusiasts and engineering buffs! Ever wondered how we make sure the bits and pieces in our cars or ships, especially the welded ones, don’t just decide to call it a day when things get tough? Well, I’ve been diving deep into something super cool called Rotary Friction Welding (RFW), a nifty way to join metals, particularly carbon steels like C35 and C45. It’s a big deal in the automotive and marine worlds, but here’s the kicker: figuring out how long these welded joints will last under repeated stress, what we call low-cycle fatigue life, especially when you’re joining different types of steel, has been a bit of a gray area. Until now, that is!

We’re talking about a journey into the heart of steel, stress, and some seriously smart AI. So, grab a cuppa, and let’s get into it!

So, What’s the Big Deal with Low-Cycle Fatigue?

Imagine bending a paperclip back and forth. It doesn’t take many bends before it snaps, right? That’s kind of like low-cycle fatigue (LCF) in metals. We’re talking about situations where metals are subjected to pretty high stress or strain, pushing them beyond their comfy elastic limits, usually in fewer than 10,000 cycles. Each cycle causes a tiny bit of microplastic deformation, and this adds up, eventually leading to failure. Ouch!

Understanding and predicting this fatigue life is super crucial. If a critical component in your car engine or a ship’s hull fails unexpectedly, well, that’s not a good day for anyone. That’s why strain-based prediction methods are so important – they help us assess how durable these materials are under intense conditions. We often lean on classic equations like the Coffin-Manson relation to help us out here, but as you’ll see, we’re taking things a step further.

The Magic of Rotary Friction Welding (RFW)

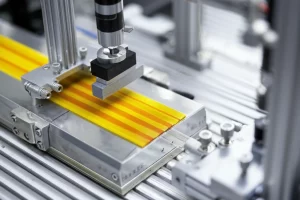

Now, let’s talk about RFW. Picture this: you take two pieces of metal, clamp one so it can’t move, and spin the other one really fast while pushing them together. The friction generates a heck of a lot of heat, making the ends of the metal soft and plastic-like. Then, you stop the spinning and give them one final, mighty push. Bam! They’re welded. It’s a solid-state joining process, meaning the metal doesn’t actually melt, which can be great for maintaining material properties.

But, like any heating process, RFW can change the microstructure of the steel, especially around the weld. And these changes can significantly impact its fatigue life. The parameters you use for RFW – things like how much pressure you apply (friction pressure), how fast you spin it, and for how long – are absolutely critical. Some studies, like one by Serdar Mercan and his team, found that higher friction pressures (from 30 to 280 MPa) and longer times (4-8 seconds) could actually weaken tensile and fatigue strengths in certain dissimilar joints. Our approach, however, suggests something a bit different, especially when we fine-tune these parameters.

We’ve been particularly interested in what happens when you weld C35 and C45 carbon steels – sometimes joining the same types (C35-C35 or C45-C45) and sometimes different ones (C35-C45). The goal? To get the strongest, most durable weld possible.

Previous Research: What Have Others Found?

We’re not the first to look into this, of course! Yan et al. used some clever modeling to look at fatigue life distributions in RFW joints. Torsakul et al. found that annealing RFW-treated C45 steel could boost its hardness and tensile strength. And Madyan et al. did some great work comparing similar and dissimilar RFW carbon steel joints, showing that the Coffin-Manson method was pretty good at predicting fatigue life improvements.

But fatigue testing is expensive and takes a long, long time. That’s where Artificial Neural Networks (ANNs) started to pop up, showing promise in predicting strain-life fatigue properties. However, the nitty-gritty of how RFW parameters affect fatigue life under real-world loading conditions was still a bit fuzzy. This is where we thought, “Hmm, maybe we can do better!”

Our Game Plan: ANFIS to the Rescue!

This is where things get really exciting. We decided to bring in the big guns: an Adaptive Neuro-Fuzzy Inference System, or ANFIS for short. Sounds fancy, right? It kind of is! ANFIS is a brilliant hybrid that combines the learning power of neural networks (like a computer brain that learns from data) with the reasoning capabilities of fuzzy logic.

Now, what’s fuzzy logic? Introduced by Lotfi Zadeh back in 1965, it’s a way of dealing with things that aren’t just black or white, true or false. Think about describing temperature: “hot,” “warm,” “cool.” These are fuzzy terms. Fuzzy logic lets us use these kinds of imprecise, human-like rules in a mathematical way. Neural networks, on the other hand, are fantastic at spotting complex patterns in data.

So, by combining them in ANFIS, we get a system that can handle the uncertainties and complexities of predicting fatigue life with much better accuracy than traditional methods alone. Our main goal was to develop a predictive model for the low-cycle fatigue life of these RFW carbon steel joints using ANFIS. We also wanted to:

- Run our own experiments to test the tensile and fatigue properties of the base metals and the RFW joints.

- Compare how similar (e.g., C45-C45) and dissimilar (e.g., C35-C45) joints fared under different friction pressures.

- And, of course, see how well our ANFIS model stacked up against the actual experimental data.

We figured that if we could nail this, it would be a huge step forward, offering a more accurate and reliable way to predict fatigue life, especially for those tricky dissimilar carbon steel joints. This could save a lot of time and money on physical testing down the line!

Getting Our Hands Dirty: The Experimental Setup

Alright, let’s talk about how we actually did this. We didn’t just sit around theorizing; we got busy in the lab! We prepared over 66 carbon steel specimens. These included our base metals, C35 and C45, and then various welded combinations: C35 welded to C35, C45 to C45, and the dissimilar C35 to C45. For the welding, we used RFW with three different friction pressures: 25, 30, and 35 MPa. We also carefully controlled things like friction time, making sure we got good, defect-free welds.

Once we had our welded samples (and our base metal samples for comparison), it was time for testing.

- Tensile Testing: We pulled ‘em apart! Using a 100 kN universal testing machine, we stretched the specimens until they broke. This tells us things like their tensile strength (how much force they can take before breaking) and yield strength (where they start to deform permanently). We followed the ASTM A370-20 standard for this.

- Low-Cycle Fatigue Testing: This is where the real endurance test happened. We used a rotating fatigue machine (an SM1090, to be precise) and subjected the specimens to repeated stress cycles until they failed. This was done at room temperature, with a stress ratio of R = -1 (meaning the stress went from tension to compression equally) and a frequency of 60 Hz. The stress amplitudes we used varied between 361 and 781 MPa. We followed the ASTM E606-92 standard here.

To make sure our measurements were spot on, especially for crack initiation, we meticulously polished the surfaces of the RFW specimens. No hiding places for those pesky machining marks!

The Brains of the Operation: Modeling with ANFIS

With all this juicy experimental data, it was time to build our predictive model using ANFIS. As I mentioned, ANFIS is a hybrid system. Let’s break it down a bit more:

Fuzzy Logic Part: This is where we define our inputs (like friction pressure, metal type, stress level) using “membership functions.” Think of these as defining how much an input belongs to a fuzzy set, like “low pressure,” “medium pressure,” or “high pressure.” We then create a set of IF-THEN rules. For example, “IF pressure is high AND metal type is C45-C45 THEN fatigue life is long.” These rules are often based on expert knowledge or derived from the data itself.

Neural Network Part: This is the learning engine. The neural network takes our experimental data (70% for training, 15% for validation, and 15% for testing) and adjusts the parameters of the fuzzy logic system (like the shape of the membership functions and the rule outputs) to make the model’s predictions as close as possible to the actual outcomes. We used a type of ANFIS based on the Takagi-Sugeno-Kang (TSK) model, which is pretty efficient.

Why ANFIS over, say, a plain Artificial Neural Network (ANN) or a Support Vector Machine (SVM)? Well, ANNs can be a bit of a “black box” – they give you an answer, but it’s hard to see *how* they got there. ANFIS, with its fuzzy rules, is more transparent. It also tends to handle multi-dimensional data well and can be less computationally hungry for training, especially with the kind of dataset sizes we often see in materials science.

For our ANFIS models, the key input parameters included:

- Metal type (e.g., C35, C45, C35-C45)

- Friction pressure used during RFW (25, 30, or 35 MPa)

- Stress amplitude level (for one model) or strain amplitude level (for another model) applied during fatigue testing

The output, of course, was the predicted fatigue life (number of cycles to failure).

To make sure our input data was consistent, we standardized it, usually scaling values to fall within a 0 to 1 range. And to judge how good our ANFIS models were, we used standard statistical metrics like:

- Root Mean Square Error (RMSE): Gives us an idea of the average magnitude of our errors.

- Mean Absolute Percentage Error (MAPE): Tells us the average percentage error.

- Pearson’s correlation coefficient (R): Shows how well our predicted values correlate with the actual experimental values. An R-value close to 1 is what we’re aiming for!

We also used the classic Coffin-Manson equation to describe the material behavior under cyclic loading and to have an empirical model to compare against. This equation relates the strain range to fatigue life and involves parameters like fatigue strength coefficient and fatigue ductility coefficient.

Crunching the Numbers: What Did We Find?

Okay, so after all the welding, testing, and modeling, what did we actually discover? Let’s break it down.

Tensile Strength: Base Metals vs. Welded Joints

First off, looking at our base metals, C45 carbon steel was the clear winner in terms of strength. It showed a tensile strength of 910 MPa, quite a bit higher than C35’s 710 MPa. C45 also beat C35 in yield strength and modulus of elasticity. This wasn’t a huge surprise, as C45 generally has a higher carbon content, contributing to its strength.

When we looked at the welded joints, things got interesting. The stress-strain curves showed that the C45 base metal was the strongest and most ductile. The C35 base metal was next. The C35-C45 dissimilar joint welded at 35 MPa friction pressure, while still pretty good, showed lower stress and strain values compared to the C45 base metal. Importantly, we found that increasing the friction pressure (from 25 to 30 to 35 MPa) during RFW generally led to higher tensile strength in both similar (e.g., C45-C45) and dissimilar (C35-C45) joints. This suggests that higher pressure helps create a better, more consolidated weld.

Fatigue Life: The S-N Curves Tell a Story

Now for the main event: fatigue life! We plotted S-N curves (Stress amplitude vs. Number of cycles to failure).

- Base Metals: As expected, C45 steel showed better fatigue resistance than C35 steel. Higher carbon content for the win again!

- Similar RFW Joints (C45-C45 and C35-C35): For these joints, increasing the friction pressure (from 25 MPa up to 35 MPa) significantly boosted their fatigue life. The joints welded at 35 MPa could withstand higher stress amplitudes for more cycles. This makes sense – higher pressure likely means fewer defects and a stronger bond at the weld interface.

- Dissimilar RFW Joints (C35-C45): Here too, increasing friction pressure improved fatigue performance, but the improvement wasn’t quite as dramatic as with the similar joints. This is likely due to the differences in material properties between C35 and C45 (like hardness and thermal expansion). These differences can create stress concentrations at the weld interface, which can be a bit of a weak spot, even with higher welding pressures.

The takeaway message from the S-N curves was pretty clear: higher friction pressures (especially 35 MPa in our tests) generally lead to better fatigue resistance. This is likely due to better weld quality, fewer defects, and possibly some beneficial microstructural changes or work hardening at the weld interface.

Coffin-Manson: The Classic Approach

We also used the Coffin-Manson equation to analyze our fatigue data. We found that the fatigue strength coefficient (({sigma }_{f}^{,})) in the equation increased as we increased the friction pressure used to make the RFW specimens. This ties in nicely with our observation that higher friction pressure improves tensile properties. In fact, we came up with an empirical model based on the Coffin-Manson equation where the fatigue strength coefficient was about 1.52 times the ultimate tensile strength, and this gave us pretty good predictions with less than 1.3% error compared to experimental values for the coefficient itself.

ANFIS Models: Stress-Based vs. Strain-Based

Now for our star players, the ANFIS models! We developed two main ones:

- Model-1 (Stress-based): Inputs were metal type, friction pressure, stress amplitude, and total fatigue time (though fatigue time as an input for predicting fatigue life seems a bit circular, the paper mentions it as an input for the model structure description, with the output being total fatigue life cycle (2Nf). I’ll interpret it as the model predicts 2Nf based on the other three, and fatigue time might refer to friction time during welding). We used bell-shaped membership functions for the inputs and 64 IF-THEN rules.

- Model-2 (Strain-based): Inputs were metal type, friction pressure, strain amplitude, and friction time (during welding). This model used Gaussian membership functions and a whopping 256 IF-THEN rules.

For both models, we trained them with 70% of our experimental data, used 15% for validation (to make sure the model wasn’t just memorizing the training data), and the final 15% for testing (to see how well it performed on unseen data).

And the results? They were fantastic!

For Model-1 (stress-based), we achieved a correlation coefficient (R) of 0.99486 between the predicted and experimental fatigue lives.

For Model-2 (strain-based), it was even slightly better, with an R-value of 0.99843!

These are incredibly high correlation values, telling us that our ANFIS models were doing an excellent job of predicting the fatigue life based on the input parameters.

ANFIS vs. The World: How Do Our Predictions Stack Up?

This is the moment of truth! We compared the predictions from our ANFIS models with the actual experimental results and also with the predictions from our empirical model (based on Coffin-Manson). We focused on the specimens welded at the optimal 35 MPa friction pressure.

For the RFW C35-C35 weld, ANFIS Model-1 (stress-based) was incredibly close to the experimental results, with a Mean Absolute Percentage Error (MAPE) that was practically zero (not exceeding 0.00003!).

For the RFW C35-C45 dissimilar specimen, when we compared the strain-based ANFIS Model-2 with the experimental data and the empirical model:

- The empirical model had a MAPE of 0.00566 (still very good).

- ANFIS Model-2 had an even lower MAPE of 0.00062!

This showed that both our ANFIS models were highly accurate, and ANFIS Model-2 (strain-based) even outperformed the already good empirical model. It really highlights how powerful ANFIS can be for this kind of complex prediction task.

So, What Does This All Mean for the Real World?

This isn’t just an academic exercise; these findings have some pretty cool practical implications.

- Better Design: Industries like automotive and marine manufacturing can use these optimized RFW parameters (like those higher friction pressures of 25-35 MPa) to make components like drivetrain parts, axles, ship hulls, and propellers more durable and resistant to fatigue.

- Cost Savings: The ANFIS model offers a potentially faster and cheaper way to predict fatigue life compared to doing tons of expensive and time-consuming physical tests. This is huge for rapid prototyping and quality assurance. Think aerospace, where every gram and every safety check counts!

- Handling Dissimilar Materials: Our work provides a more reliable way to predict fatigue life for those tricky dissimilar material joints, which are becoming more common in advanced manufacturing.

Ultimately, this research can help make welded joints stronger, reduce testing costs, and improve the overall safety and reliability of all sorts of engineering structures. How cool is that?

Wrapping It Up: Key Takeaways

So, what are the big messages here?

- Friction Pressure Matters: We confirmed that higher friction pressures (25-35 MPa) in RFW significantly boost both the tensile strength and fatigue life of carbon steel joints, both similar and dissimilar.

- Coffin-Manson Still Useful, But Improvable: The classic Coffin-Manson equation, when adapted, can give decent fatigue life predictions, and we found a good link between its fatigue strength coefficient and friction pressure.

- ANFIS is a Star: Our Adaptive Neuro-Fuzzy Inference System (ANFIS) models proved to be incredibly accurate at predicting low-cycle fatigue life for these RFW joints, outperforming even our refined empirical model. This is a big step forward for predictive modeling in this field!

- Strain-Based ANFIS Shines: The ANFIS model that used strain amplitude as an input (Model-2) was particularly impressive.

This research really pioneers the use of these advanced modeling techniques in the RFW world and gives us some new practical guidelines for optimizing welding conditions. It’s all about making things last longer and perform better, safely!

What’s Next on the Horizon?

As always in science, answering one question opens up a dozen more! We’re thinking about a few things for the future:

- More Materials: It would be great to test a wider range of steel grades and even other metals to see how they behave with RFW and ANFIS modeling.

- More Complex Models: We could explore even more sophisticated ANFIS setups or hybrid models that combine ANFIS with other machine learning tricks. Maybe even bring in big data analytics if we get enough data!

- Real-World Conditions: Testing under more varied and realistic loading conditions, and even considering environmental factors like corrosion or temperature changes, would be super valuable.

- High-Cycle Fatigue: Our focus was low-cycle, but looking at high-cycle fatigue (many more, smaller stress cycles) would give a fuller picture of long-term durability.

- Scaling Up: Taking these findings and developing practical guidelines for specific industries would be the ultimate goal.

It’s an exciting field, and I reckon we’ll see a lot more of these smart AI-driven approaches helping us understand and improve materials and manufacturing processes. Thanks for sticking with me on this deep dive – hope you found it as fascinating as I do!

Source: Springer