Printing Smart Fibers Onto Anything? Yes, Please!

Hey there! Ever looked at your favorite mug, your trusty old wrench, or even your comfy face mask and thought, “Man, I wish this could *do* something extra?” Like, sense the temperature, monitor your breathing, or connect to your phone? Adding cool tech functions to everyday stuff sounds awesome, right? But sticking rigid, flat electronics onto curvy, bumpy, or even squishy things? Yeah, not so easy. It usually involves complicated steps, extra adhesives, and often messes up the original look or feel of the object.

Well, guess what? Science just cooked up something pretty neat that could totally change the game. We’re talking about a way to print conductive microfibers – tiny, smart threads – directly onto almost *anything*, regardless of its shape or surface. Think of it as giving your stuff a temporary, high-tech upgrade, right when and where you need it.

The Problem with Adding Smartness

Adding sensing or electronic capabilities to existing objects is a fantastic idea. Imagine a face mask that monitors your breath, or a robotic hand that can ‘feel’ like a human finger. These kinds of enhancements can extend the life and utility of things we already own, which is great for our wallets and the planet. But the traditional methods? They hit some snags:

- 3D Printing: Can make custom shapes, sure, but printing directly onto an existing, textured object? Precision gets tricky, and the texture can mess with the print quality.

- Spraying Inks: Simple in concept, but often messy, can change the object’s appearance drastically, and whether it works depends a lot on how the ink wets the surface. Not very versatile.

- Pre-fabricated Layers: Making smart films or fiber meshes separately and then trying to stick them on? Requires extra glue (which can block the function or look) and is super difficult to get them to conform perfectly to complex curves or porous surfaces.

We needed something more flexible, more adaptive, and less… well, obstructive!

Enter Adaptive Fiber Printing: The Magic Touch

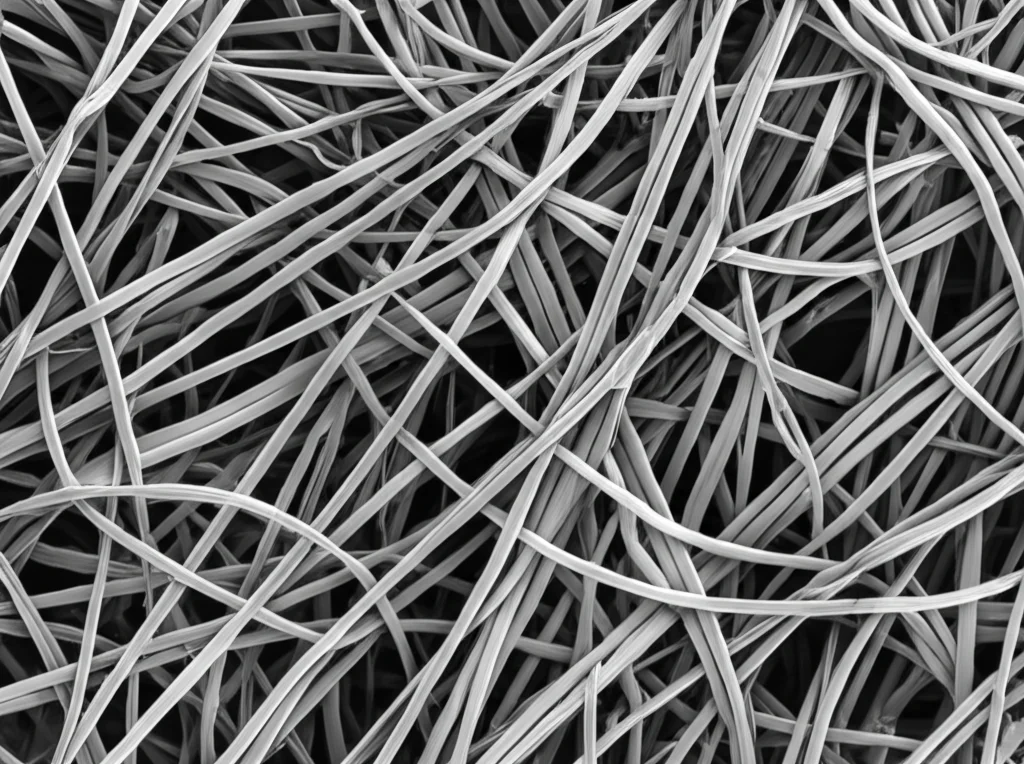

This new strategy is pretty clever. Instead of trying to stick something *onto* a surface, it *creates* the conductive pattern directly *on* it. It uses a technique called in situ orbital spinning. Sounds fancy, but here’s the gist:

- A special conductive ink (made with stuff like PEDOT:PSS or silver nanoparticles) is fed through a needle.

- A tiny, rotating arm gently scratches a drop of this ink, pulling out a thin jet.

- This jet gets stretched and narrowed as it travels towards the object you want to upgrade.

- The cool part? It lands on the object while it’s still a bit semi-wet.

This ‘semi-wet’ state is the secret sauce! When the fiber lands, it’s still pliable enough to conform perfectly to the surface, whether it’s flat, curved, or even porous. It sticks right there and then, no extra adhesive layer or pressing needed. It’s a seamless, one-step process from ink to functional fiber on your object. This mechanical pulling process, unlike electrospinning, avoids the ‘jet whipping’ chaos, allowing for much more controlled and precise patterns.

Why These Fibers Are So Cool

Okay, so they stick easily. Big deal, right? Well, it is, but there’s more! These microfibers have some fantastic properties:

- Adaptive Champions: They work on a huge range of materials and shapes – from smooth plastic and glass to artificial leather and even super-porous graphene aerogels. Curvy pencil? Bumpy tool handle? No problem!

- Practically Invisible: They’re incredibly thin (micrometer scale) and can be printed in sparse patterns with large gaps between them. This means they are highly transparent (around 90% transmittance for visible light!). You can put them on a screen, and you can still see what’s underneath.

- Breathable and Permissive: The open network lets air and moisture pass right through. Great for sensors!

- EM-Friendly: Crucially, they minimally obstruct electromagnetic waves, even in the gigahertz range used by Wi-Fi and Bluetooth. This means you can put them on your smartwatch or phone case without killing your signal!

- On-Demand e Tunable: You can design the pattern, density, and orientation of the fibers precisely for the specific object and function you need. Need a denser pattern for better conductivity? Done. Need a more open one for transparency? Easy.

- Sustainable e Cost-Effective: This method uses minimal material and energy compared to traditional microfabrication or even 3D printing. Plus, the fibers are transient – you can wipe them off when you’re done, often allowing the base object (like a 3D printed frame) to be reused. Minimal waste!

Putting the Fibers to Work: Real-World Magic

So, what can we actually *do* with these super-adaptive, unobtrusive conductive fibers? The possibilities are pretty exciting, and the researchers demonstrated a bunch:

- Breath Sensing Face Masks e Smartwatches: By printing PEDOT:PSS fibers onto a small frame that clips onto a face mask valve or a smartwatch, you can create a sensor that detects changes in humidity caused by breathing. It can monitor your breath patterns without getting in the way or blocking the watch screen.

- Giving Robots a ‘Sense of Touch’: They printed fibers onto a robotic finger. When a human finger touched it, the fiber layer acted like a dry electronic skin, able to pick up faint biopotential signals like ECG (electrocardiogram) from the human body.

- Smart Everyday Objects: Imagine your humble pencil becoming a health monitor! By wrapping it in fibers, it can detect EMG (electromyography) signals from your hand muscles as you write, showing how much force you’re using. A plier handle, normally just insulated rubber, could also be wrapped to measure ECG or EMG while you work. The fibers conform perfectly to the curves and don’t stop you from using the object normally.

- Transparent Heaters: Silver nanoparticle fibers are highly conductive. They printed them over an NFC tag. The fibers could heat up when power was applied, but because they’re so sparse and thin, they didn’t block the radio waves, and the smartphone could still read the NFC tag!

- Energy Harvesting Coasters: PEDOT:PSS has thermoelectric properties (it can convert heat differences into electricity). They wrapped a coaster in these fibers. Place a hot mug on it, and the temperature difference between the top and bottom generates a small voltage and current! Free, tiny energy!

- Connecting Tricky Materials: Graphene aerogels are amazing for gas sensing because they’re super porous. But connecting them to electronics usually means covering up those pores with traditional electrodes, ruining their sensing ability. With these microfiber arrays, you can ‘sandwich’ the aerogel between two layers of fibers. The fibers are so open, they don’t block the pores, allowing the aerogel to do its job detecting gases like formaldehyde while being connected to a circuit.

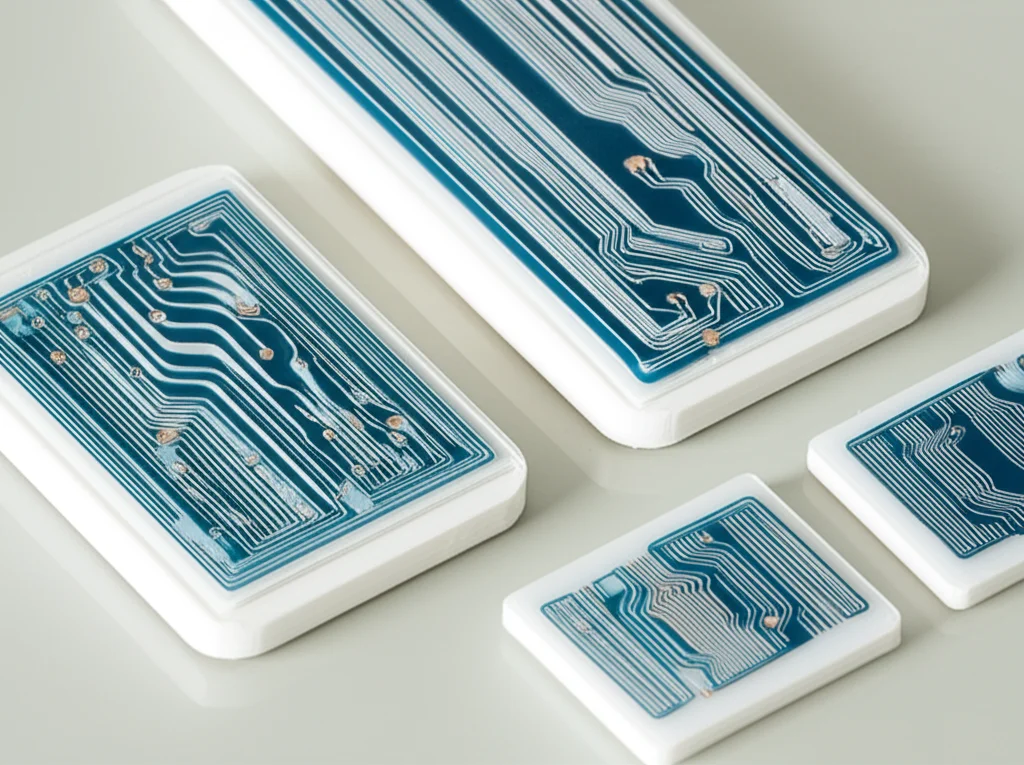

Building Blocks for a Smart Future

Beyond just printing directly, they also showed how you could print fibers onto small, interlocking 3D-printed plastic frames. These frames act like “Lego blocks” for smart functions. You can assemble them into different 3D shapes (like a multi-tier sensor or a box) to detect spatial moisture flow, then take them apart and reconfigure them for a different task. When the fibers are no longer needed or get damaged, you can just wipe them off the reusable frame with a wet tissue, print new ones, and you’re good to go. This reconfigurable, low-waste approach is pretty exciting.

Looking Ahead: The “Fiber-of-Things”

This adaptive fiber deposition technique feels like a significant step forward. It solves some big problems with adding electronic functions to the incredibly diverse world of everyday objects. It’s on-demand, highly adaptable, minimally intrusive, and surprisingly sustainable.

The researchers reckon this opens the door to a “Fiber-of-Things” (FoT) future. Imagine a world where adding a temporary sensor to your backpack, making your gardening tool smart, or giving a toy new interactive features is as simple as printing a pattern of these tiny, smart fibers onto it. Expanding the types of materials the fibers can be made from could unlock even more functions, leading to multi-functional integrations on the fly.

It’s a flexible, efficient, and low-impact way to bring the internet-of-things connectivity to… well, almost *anything*!

So yeah, this adaptive fiber printing? It’s not just cool lab tech; it’s a game-changer for making our everyday objects a whole lot smarter, without messing them up or creating tons of waste. Pretty exciting stuff!

Source: Springer